Do you have a question about the Miller Invision 456MP and is the answer not in the manual?

Explains the meaning of safety symbols used throughout the manual.

Details potential dangers associated with arc welding processes and electrical shock.

Covers symbols related to specific hazards during installation, operation, and maintenance.

Lists key safety standards and codes relevant to welding equipment operation.

Provides information on electromagnetic fields and their potential effects during welding.

Details the technical specifications, including input power and output ratings.

Explains duty cycle limitations and procedures to prevent overheating.

Illustrates the voltage and amperage output capabilities of the unit in different modes.

Guides on choosing a suitable and safe location for operating the welding unit.

Provides information on connecting weld output terminals and selecting appropriate cable sizes.

Instructions for selecting and configuring the correct input voltage for the unit.

Step-by-step guide for safely connecting the welding machine to the input power source.

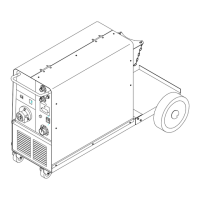

Identifies and explains the functions of all controls on the front panel.

Details the meter readings at idle and while welding for different operational modes.

Explains the synergic control system and its operational modes for automated welding.

Describes initial display and setup for Manual Pulse MIG, MIG, and Stick welding modes.

Guides on selecting pulse programs and adjusting parameters for optimal welding.

Provides a summary of the available pre-programmed welding settings.

Lists detailed parameters for each program, including wire type, size, gas, and settings.

Outlines recommended maintenance procedures for ensuring unit longevity and performance.

Offers solutions for common operational problems and error conditions.

| Brand | Miller |

|---|---|

| Model | Invision 456MP |

| Category | Welding System |

| Language | English |