What to do if the drive motor becomes inoperative in Miller Welding System?

- AAshley WebsterAug 8, 2025

If the drive motor becomes inoperative, cycle the unit power off and back on again.

What to do if the drive motor becomes inoperative in Miller Welding System?

If the drive motor becomes inoperative, cycle the unit power off and back on again.

What to do if the contact tip has stuck to the workpiece with Miller millermatic 180 auto-set?

If the contact tip has stuck to the workpiece, release the gun trigger, turn off the unit, and remove the contact tip from the workpiece.

What to do if contact tip is shorted to workpiece and Miller millermatic 180 auto-set Welding System shuts down welding output?

If the contact tip is shorted to the workpiece and the unit shuts down welding output, release the gun trigger to reset the unit.

Explains hazard symbols used throughout the manual for safety.

Details potential dangers related to arc welding processes.

Covers symbols for fire, falling equipment, moving parts, and static hazards.

Lists chemicals known to cause cancer or reproductive harm.

Lists key safety standards and their sources for reference.

Explains electromagnetic fields and their potential effects on medical implants.

Details voltage, amperage, input, KVA, KW, weight, and dimensions for 115V model.

Details voltage, amperage, input, KVA, KW, weight, and dimensions for 230V model.

Explains duty cycle percentages and actions for unit overheating.

Illustrates minimum and maximum voltage/amperage output capabilities.

Step-by-step guide to properly install the welding gun.

Instructions for attaching the work clamp securely for optimal performance.

Details how to route the work cable inside the welding unit.

Provides polarity and cable connection details for different welding processes.

Step-by-step guide on how to change the welding polarity.

Instructions for connecting the shielding gas cylinder and regulator.

Identifies the location of the serial and rating labels on the unit.

Guide for selecting a location and connecting the 115 VAC input power.

Guide for selecting a location and connecting the 230 VAC input power.

Recommendations for electrical service for the 230 VAC model.

Steps for installing the wire spool and adjusting hub tension.

Detailed instructions for threading the welding wire through the drive system.

Procedure for safely removing the MIG gun from the power source.

Guide for installing the switch for an optional spool gun.

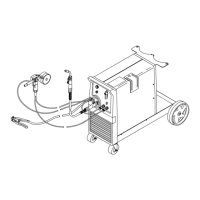

Instructions for connecting the spool gun to the Millermatic unit.

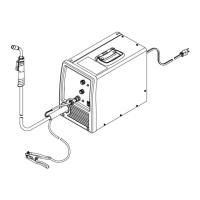

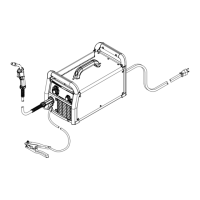

Overview and function of controls for the 115V Auto-Set model.

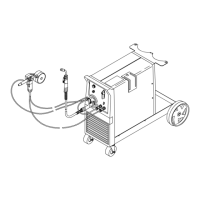

Overview and function of controls for the 230V Auto-Set model.

Recommended settings for mild steel welding on the 115V model.

Recommended settings for mild steel welding on the 230V model.

Outlines regular maintenance tasks and their frequency.

Explains the overload protection system and how to reset it.

Details protection circuits for the drive motor and contact tip.

Instructions for replacing the drive roll or wire inlet guide.

A table listing common problems and their remedies.

Provides the overall circuit diagram for the welding unit.

Illustrates the standard setup for MIG welding processes.

Provides guideline settings for MIG welding based on material and wire.

Demonstrates correct techniques for holding and positioning the welding gun.

Explains how gun angle, travel speed, and stickout influence weld bead shape.

Describes proper gun movements for different weld joint types.

Illustrates common issues leading to poor weld bead quality.

Shows examples of desirable weld bead characteristics.

Identifies causes and corrective actions for excessive spatter.

Lists potential causes and solutions for weld porosity.

Addresses issues related to excessive weld penetration.

Provides solutions for insufficient weld penetration.

Offers remedies for incomplete fusion in welds.

Explains how to prevent or fix burn-through during welding.

Addresses causes and solutions for wavy weld beads.

Covers methods to minimize or correct weld distortion.

Lists common shielding gases and their applications.

Guide for resolving issues with semiautomatic welding equipment.

Lists recommended spare parts for the equipment.

Details optional drive rolls available for the feed head assemblies.

Lists optional accessories like replacement guns.

Outlines the terms, conditions, and periods of the limited warranty.

Lists components and conditions not covered by the warranty.

| Input Hz | 60 Hz |

|---|---|

| Output Amperage Range | 30 - 180 A |

| Welding Process | MIG (GMAW) |

| Input Phase | Single Phase |

| Rated Output | 130A at 20V (20% Duty Cycle) |

| Wire Diameter | 0.023-0.035 in |