OM-251981 Page 12

SECTION 7 − SELECTING AND PREPARING A TUNGSTEN

FOR DC OR AC PHASE MACHINE WELDING

Ref. gtaw_Phase_2018−01

! Whenever possible and practical, use DC weld output instead of AC weld output.

7-1. Selecting Tungsten Electrode (Wear Clean Gloves To Prevent Contamination Of Tungsten)

A. Select Tungsten Electrode

. Not all tungsten electrode manufacturers use the same colors to identify tungsten type. Contact the tungsten electrode manufacturer or refer-

ence the product packaging to identify the tungsten you are using.

Amperage Range - Gas Type♦ - Polarity

Electrode Diameter (DCEN) − Argon

Direct Current Electrode Negative

(For Use With Mild Or Stainless Steel)

AC − Argon

Unbalanced Wave

(For Use With Aluminum)

2% Ceria Or 1.5% Lanthanum

.040” (1 mm) 15-80 15-80

1/16” (1.6 mm) 70-150 70-150

3/32” (2.4 mm) 150-250 140-235

1/8” (3.2 mm) 250-400 225-325

Pure Tungsten

.040” (1 mm) Pure Tungsten Not Recommended

For DCEN − Argon

10-60

1/16” (1.6 mm) 50-100

3/32” (2.4 mm) 100-160

1/8” (3.2 mm) 150-210

♦Typical argon shielding gas flow rates are 10 to 25 CFH (cubic feet per hour).

Figures listed are a guide and are a composite of recommendations from American Welding Society (AWS).

7-2. Preparing Tungsten Electrode For Welding With Phase Control Machines

! Grinding the tungsten electrode produces dust and flying sparks which can cause injury and start fires. Use

local exhaust (forced ventilation) at the grinder or wear an approved respirator. Read MSDS for safety infor-

mation. Consider using tungsten containing ceria, lanthana, or yttria instead of thoria. Grinding dust from

thoriated electrodes contains low-level radioactive material. Properly dispose of grinder dust in an environ-

mentally safe way. Wear proper face, hand, and body protection. Keep flammables away.

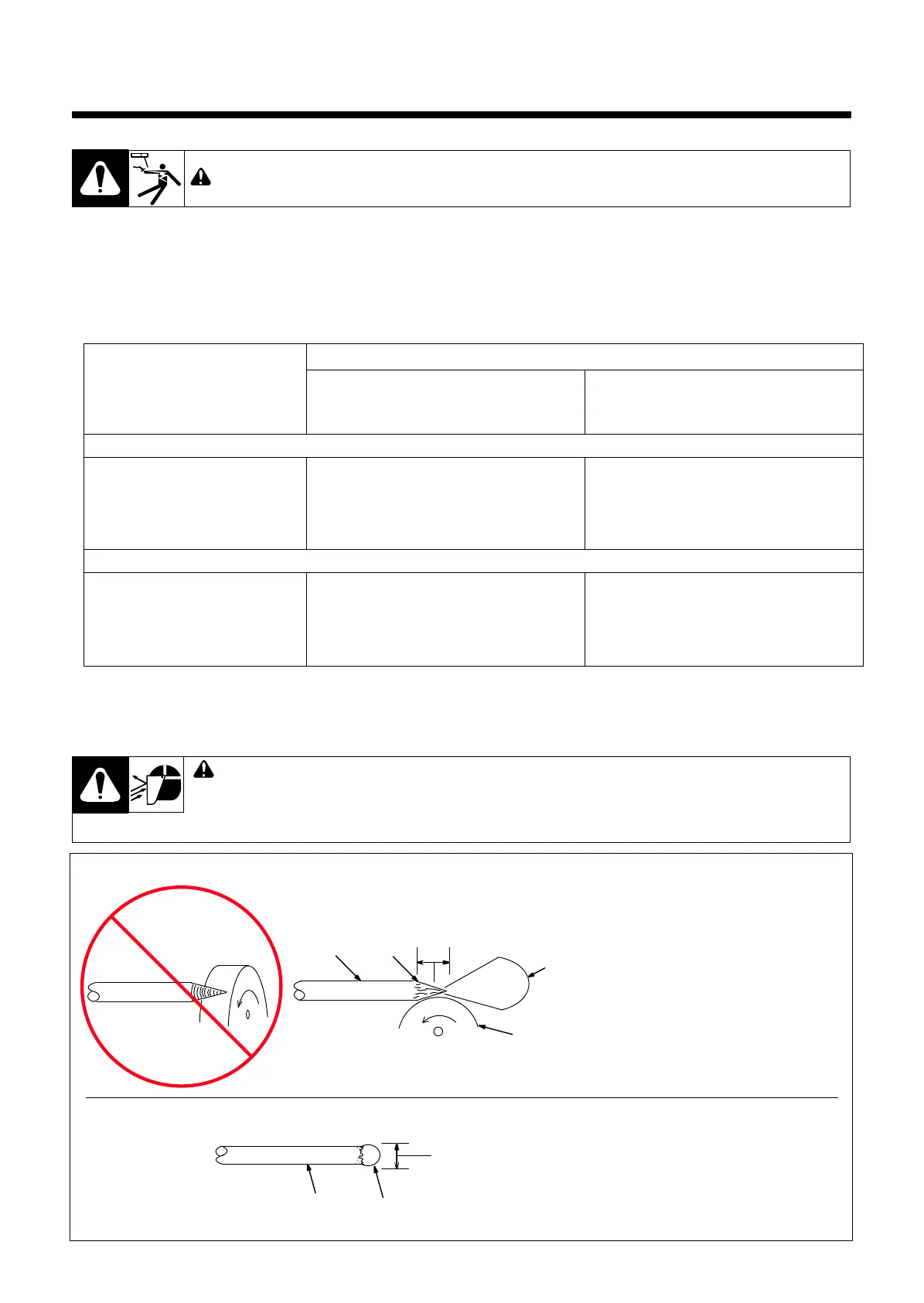

A. Preparing Tungsten For DC Electrode Negative (DCEN) Welding

1 Grinding Wheel

Grind end of tungsten on fine grit, hard

abrasive wheel before welding. Do not use

wheel for other jobs or tungsten can become

contaminated causing lower weld quality.

2 Tungsten Electrode

A 2% ceriated tungsten is recommended.

3 Ideal Grind Angle Range: 15° to 30°

. 30 degrees is the recommended elec-

trode grind angle.

4 Straight Ground

Grind lengthwise, not radial.

1 Tungsten Electrode

A pure tungsten is recommended..

2 Balled End

Ball end of tungsten by applying AC amper-

age recommended for a given electrode

diameter (see Section 7-1). Let ball on end of

the tungsten take its own shape.

B. Preparing Tungsten For AC Welding

1 − 1-1/2 Times

2

Electrode Diameter

Causes Wandering Arc

1

Wrong Tungsten Preparation

Radial Grinding

Ideal Tungsten Preparation − Stable Arc

1

3

2

15° to 30°

4

1-1/2 To 4 Times

Electrode Diameter

Loading...

Loading...