3. Remove drain plug located on bottom of main bearing housing and allow bearing hous-

ing to drain completely. Clean magnetic drain plug and re-install it in bottom of bearing

housing.

4. Strictly following lubrication specifications below, refill bearing housing using 1/2" plastic

tube closest to the drive pulley. After refilling bearing housing, re-install cork stoppers.

CAUTION: Do not spill oil. Oil spilled on components such as the timer or

controls may cause machine to malfunction.

ÏLubrication Specifications

Component

Lubricant

Type

Amount of

Lubricant

Main Bearing H ousing H igh quality SAE 30 heavy duty

oil, non-detergent if possible

22 ounces

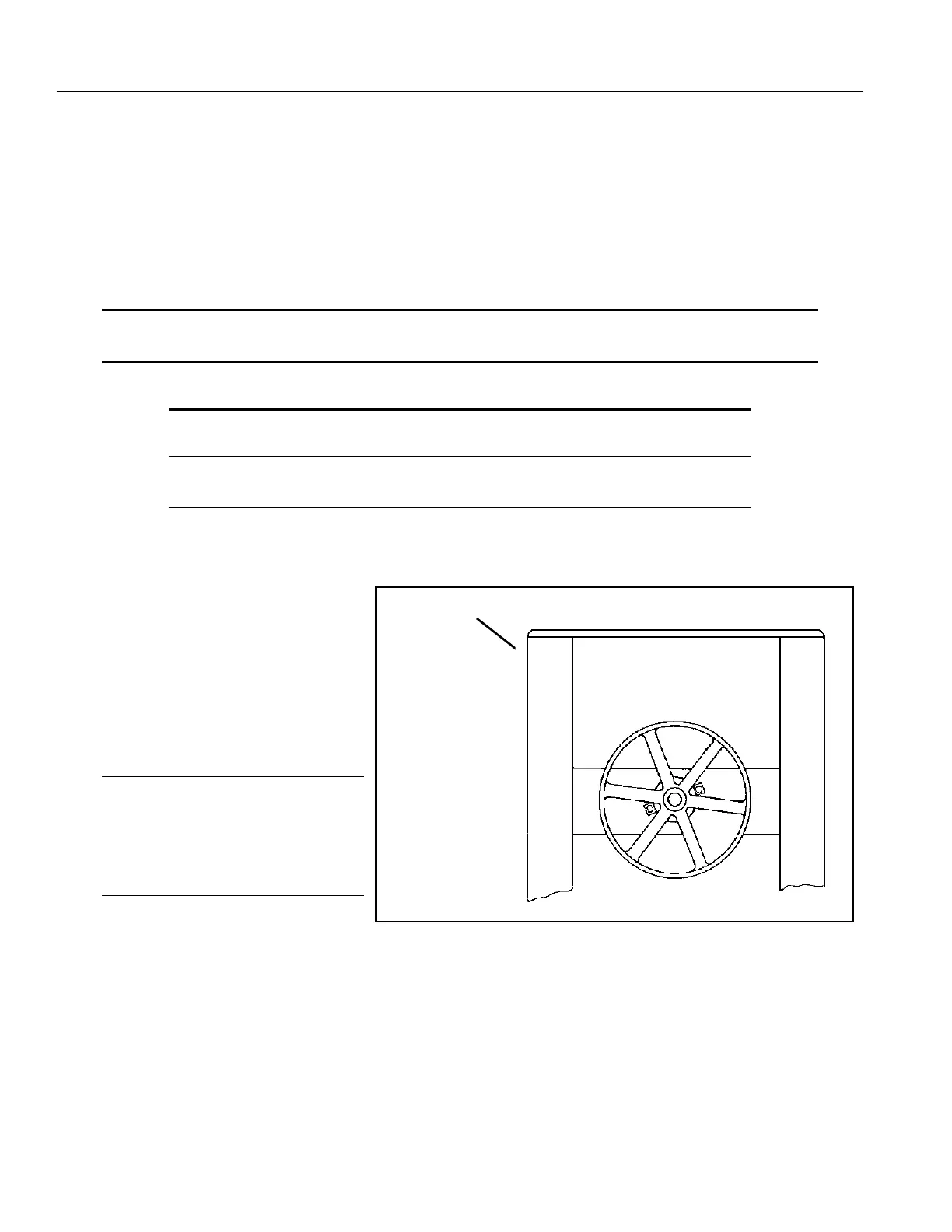

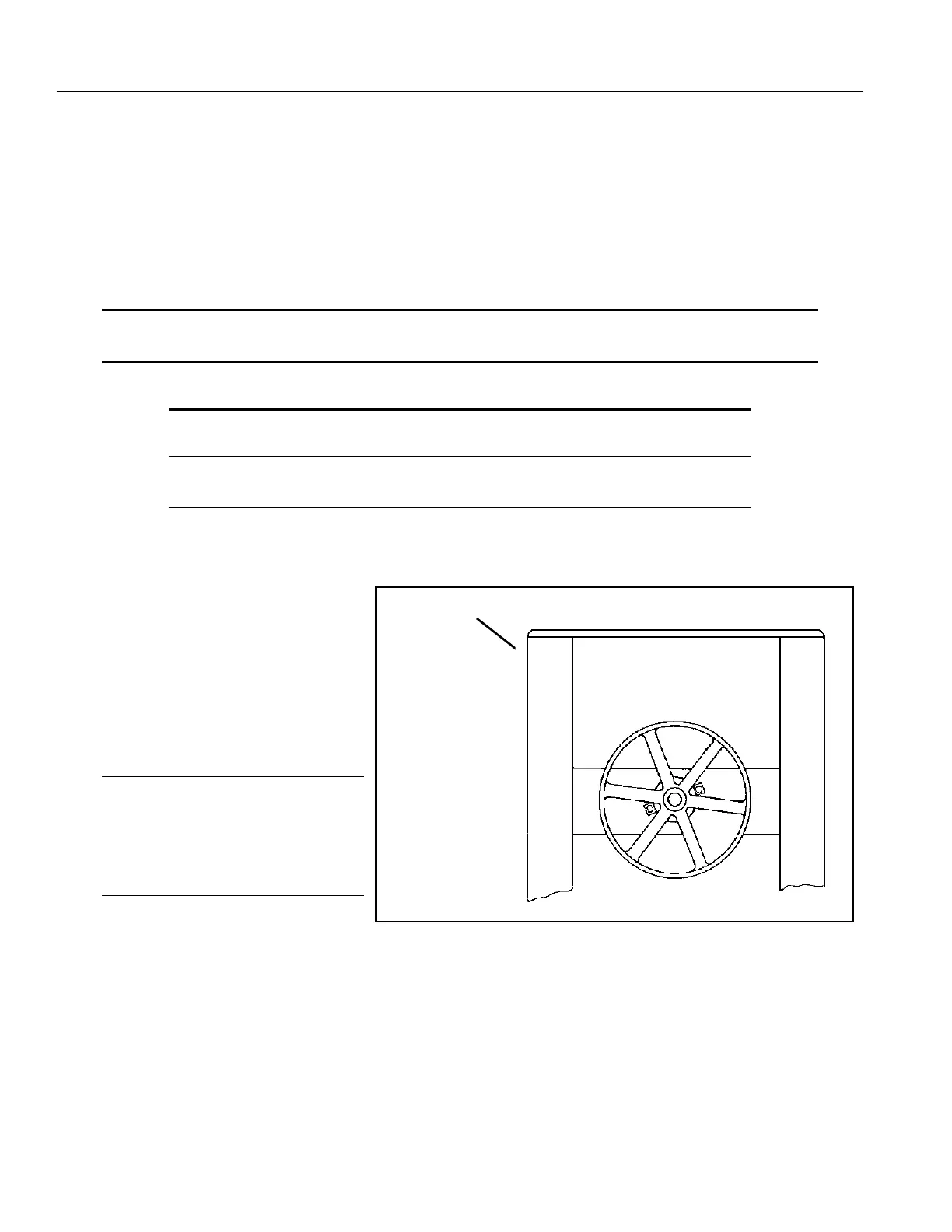

Support Bolt Inspection

Inspect Main Bearing support bolts

(Figure 1) for tightness.

Foundation Bolts

Inspect six foundation bolts for

tightness.

Two foundation bolts are located

within machine console. It is most im-

portant to inspect these bolts for tight-

ness as they are located directly below

the Main Shaft. Remove rear belt

guard for access to these bolts.

Main Bearing Housing

support bolts

ÎFigure 1 (MSSM0705AE)

ÎSupport Bolt Locations

PREVENTIVE MAINTENANCE/LUBRICATION MSSM0705AE/90066V (2 of 2)

Loading...

Loading...