SHIPPING AND RECEIVING

Each Minster Model 101 OBI/OBS Series press is

carefully prepared for shipment to protect the press

during transit and to enable the customer to install the

press with a minimum of reassembly when it arrives at

its destination.

When the press is received, it should be inspected

immediately for any visual signs of damage. If any dam-

age has occurred, notify MINSTER and the CARRIER

for claims inspection. However, with F.O.B. shipments,

a claim must be presented to the CARRIER by the cus-

tomer since title of the equipment changes to the cus-

tomer when shipment is accepted by the carrier.

UNLOADING AND LIFTING

REMOVE all accessories and boxes attached to the

skids so that these parts will not be damaged in han-

dling the press. The press should remain on the skids

until it is placed under the handling equipment.

WARNING

MAKE CERTAIN THAT THE CRANE OR HOIST

AND ASSOCIATED CABLES, CHAIN AND HOOKS

ARE CAPABLE OF SAFELY LIFTING THE WEIGHT

INVOLVED.

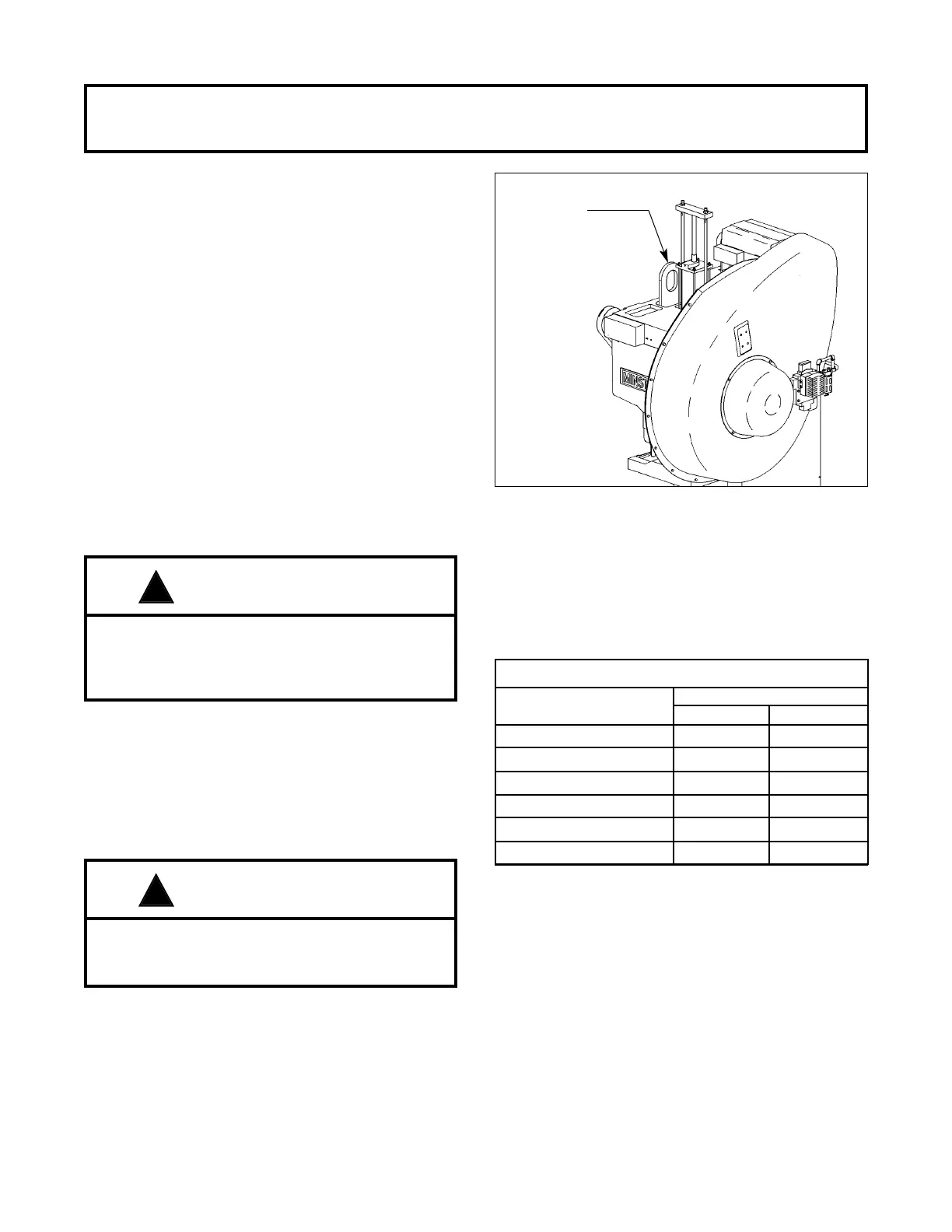

Two (2) lifting lugs are provided on the top of the press.

(See Figure 1C.) Riggers should be cautioned never to

place lifting slings around the press crankshaft. Work-

men should also be instructed to use adequate block-

ing when placing slings around major frame parts to

prevent cables from crushing oil lines or damaging

electrical conduit and/or other exposed components.

CAUTION

NEVER USE A FORKLIFT UNDER THE SLIDE

ASSEMBLY TO LIFT THE PRESS OR DAMAGE TO

THE SLIDE COULD OCCUR.

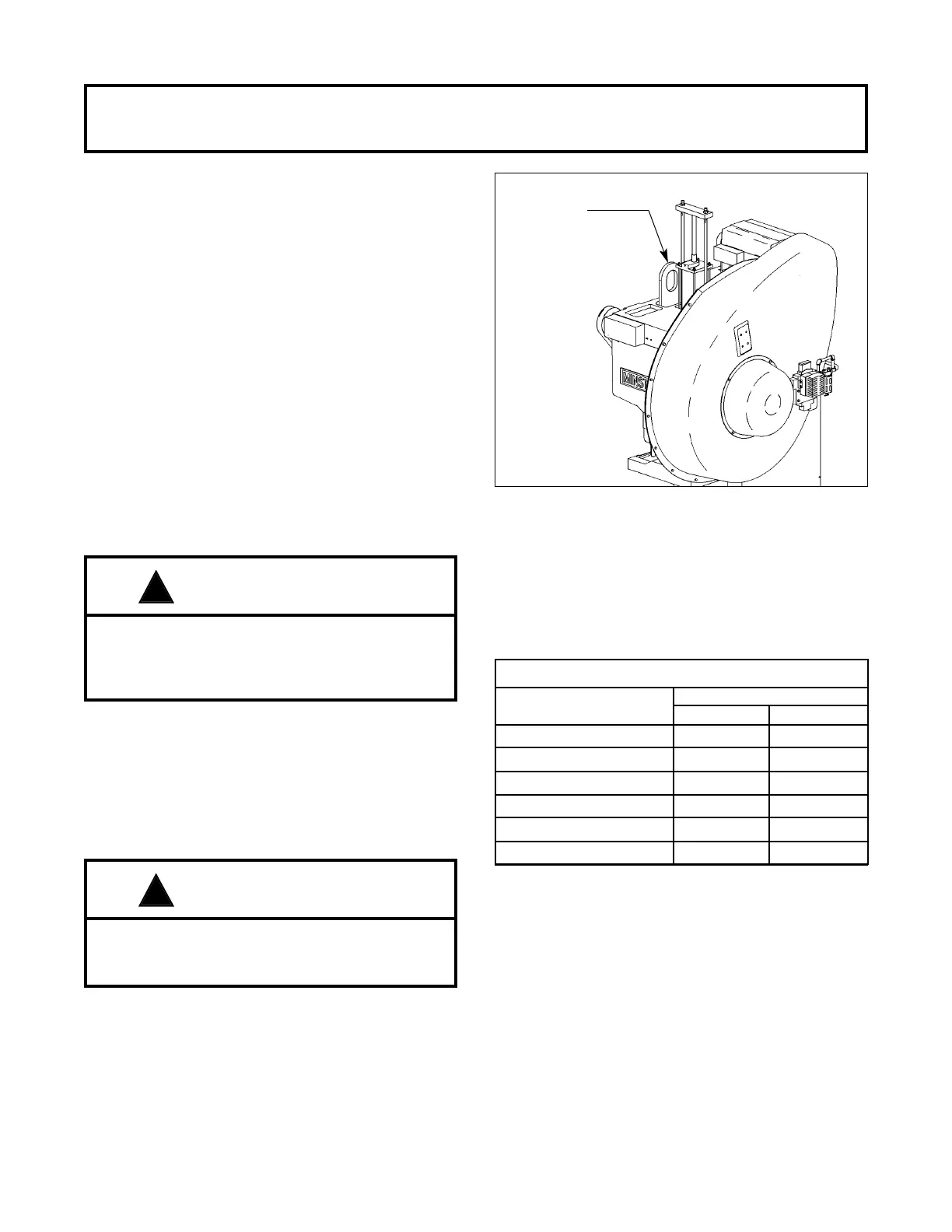

PRESS WEIGHT

The following table of press weights includes all facto-

ry supplied items mounted on the press when it is

assembled. All weights are approximate and do not

include the additional weight of dies, feeds, or other

customer-added equipment.

CLEANING

Before installing the press, clean it thoroughly to

remove cinders, rust, salt, sand and other soil that may

have accumulated during shipment. Carefully inspect

and clean all exposed areas where foreign particles

may have adhered. Use a good grade of commercial

solvent to remove slushing and rust-preventing com-

pounds. Use care when applying cleaning solvents to

the press. Make certain that the solvent used will not

cause damage to any seals that it might contact.

C - 2

PRESS INSTALLATION

Lifting Lug

(One Each Side)

Figure 1C. Lifting lug location.

!

!

PRESS WEIGHT CHART

PRESS SIZE

APPROXIMATE WEIGHT

POUNDS KILOGRAMS

No. 4 Flywheel Type 7,500 3,402

No. 5 Flywheel Type 10,000 4,536

No. 6 Flywheel Type 13,000 5,897

No. 6 Geared Type 14,200 6,441

No. 7 Flywheel Type 18,000 8,165

No. 7 Geared Type 19,000 8,618

Loading...

Loading...