Mechanical Press Parts

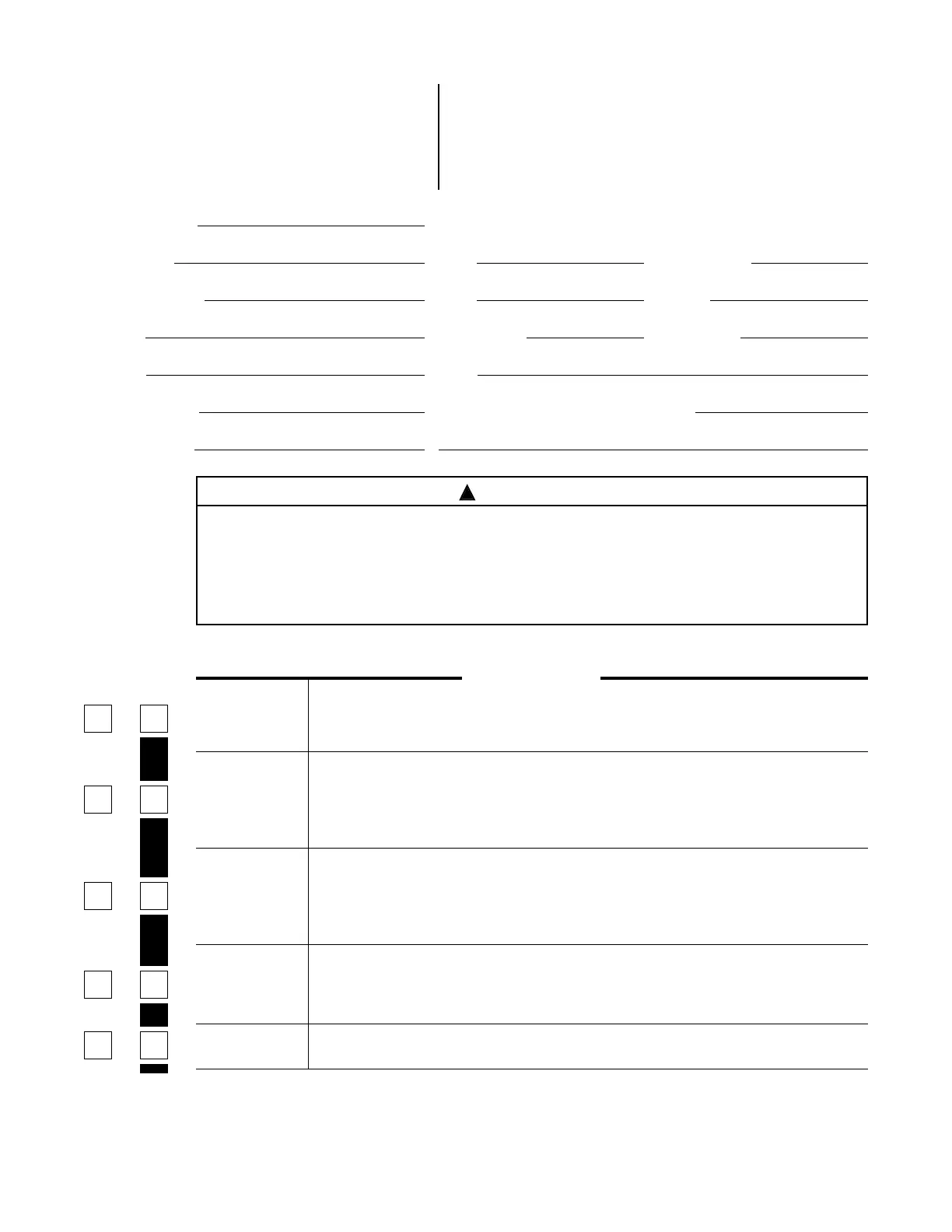

Weekly Checks

! Clean press inside and out. Remove any foreign material, rags, chips, scrap, etc. which

may have accumulated.

! Clean-up floor and area surrounding the press.

! Check flywheel (or main gear) cover to make certain it is in place and secure.

! Make certain all covers are closed and properly secured.

! Check feed and scrap shear cover, if applicable, to make certain it is in place and

secure.

! Check for any other covers that are missing or broken and replace as necessary.

! Check automatic feeding equipment for loose mounting bolts, brackets, rods and

levers. Tighten if necessary.

! Check scrap shears for dull knives and improper setting.

! Make certain gear case gear teeth and all other feed equipment bearings are properly

lubricated per feed manufacturer’s instructions.

! Check physical size of die for compatibility with press. (Die should not extend beyond

edge of slide face or bolster. Small die area may cause concentrated loading.)

! Check tonnage requirements of die or dies to be installed. (Do not exceed tonnage

capacity of press.)

! If dies are set, test press to determine if it is overloaded. Do not operate press above

maximum rated tonnage.

I - 4

MINS TER®

Press Inspection

Check List &

Maintenance Record

Auxiliary Equipment

MODEL 101 OBI/OBS Series Press

Press Serial No.

Press Model Feed

Reel

Straightener

Scrap Shear

Cradle

Stock Oiler

User’s Equip. No.

Location

Tonnage Other

Type Of Point Of Operation GuardingInstallation Date

Inspection Date

WARNING

USE EXTREME CAUTION WHEN PERFORMING INSPECTIONS. DISCONNECT POWER TO THE PRESS, LOCK

THE AIR LOCKOUT VALVE AND ELECTRICAL DISCONNECT SWITCH IN THE OFF POSITION, AND INSERT THE

DIE SAFETY BLOCK. ATTACH WARNING TAGS TO PREVENT ACCIDENTAL STARTING. MAKE CERTAIN THAT

THE FLYWHEEL HAS STOPPED TURNING. IF NECESSARY TO MOMENTARILY RESTORE ELECTRICAL POWER

OR AIR PRESSURE, MAKE CERTAIN THAT ALL PERSONS AVOID ANY PINCHING POINTS ASSOCIATED WITH

THE PRESS AND/OR ITS AUXILIARY EQUIPMENT. PRESS INSPECTIONS SHOULD BE PERFORMED ONLY BY

AUTHORIZED, EXPERIENCED PERSONNEL.

!

Cleanliness

Protective

Covers

Feeding

Equipment

(If Furnished)

Die

Installation

Overload

Satisfactory

Unsatisfactory

Loading...

Loading...