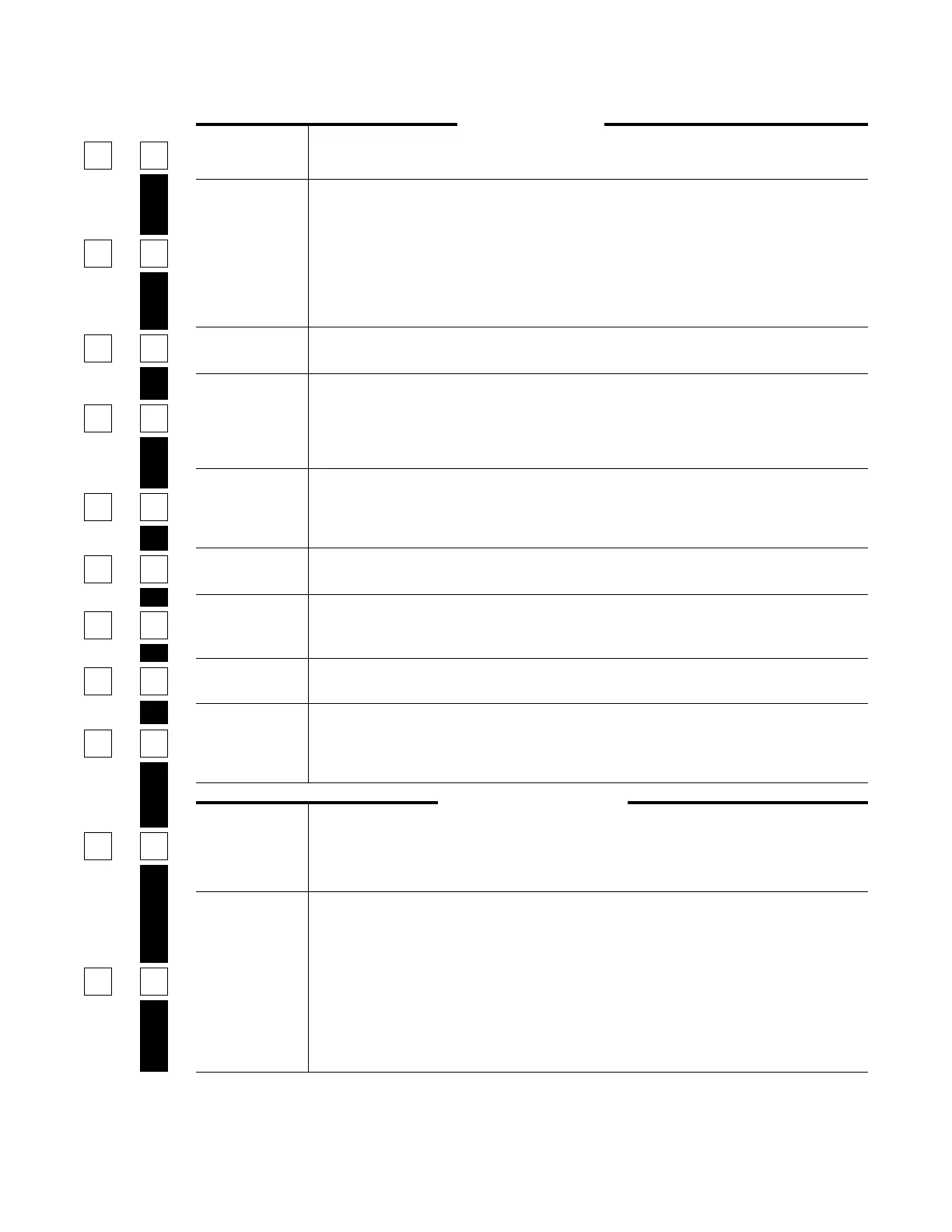

Mechanical Press Parts (Continued)

Monthly Checks

! Make certain no foreign material is lodged between bolster and bed.

! Make certain bolster is mounted securely to bed.

! Check clutch brake anchor pins for tightness.

! Check clutch for loose or broken parts.

! Check clutch for air leakage. (Procedure is explained in separate clutch manual.)

! Check brake lining wear. (Check clutch drive disc wear whenever clutch is disassem-

bled for replacement of brake linings.)

! Check clutch adjustment by measuring amount of pressure plate travel. (See clutch

manual for procedure and tolerances.)

! Perform additional checks listed in the clutch service manual.

! Check all cap screws and stud nuts for tightness.

! Replace all missing screws, nuts, and washers.

! Make certain slide adjusting motor is mounted securely.

! Check slide adjustment gears for condition and tightness on shaft.

! Check micro shutheight indicator for accuracy. (Follow procedure given in manual.)

! Check slide adjustment locking knob and pin assembly. Make certain pin is not broken

and that the adjustment setting can be locked.

! Check knockout brackets to be sure they are fastened securely and that they are not

cracked or broken.

! Check condition of clamping screws and knockout rods.

! Make certain knockout bar is straight. Repair or replace as necessary.

! Check inclining frame bracket for cracks or looseness.

! Check inclining jack assembly and attachment pins for loose or broken parts.

! Check motor sheave for looseness on motor shaft.

! Check alignment of motor sheave with flywheel sheave.

! Check motor sheave and flywheel for cracks, wear, and rough areas.

! Check v-belts for proper tension.

! Check for worn, cracked, or frayed belts.

! Check timing belts for proper tension.

! Check timing belts for worn, cracked, or frayed sections.

! Check timing belt sheaves for tightness on the shaft and for proper alignment.

! Check condition of sheaves.

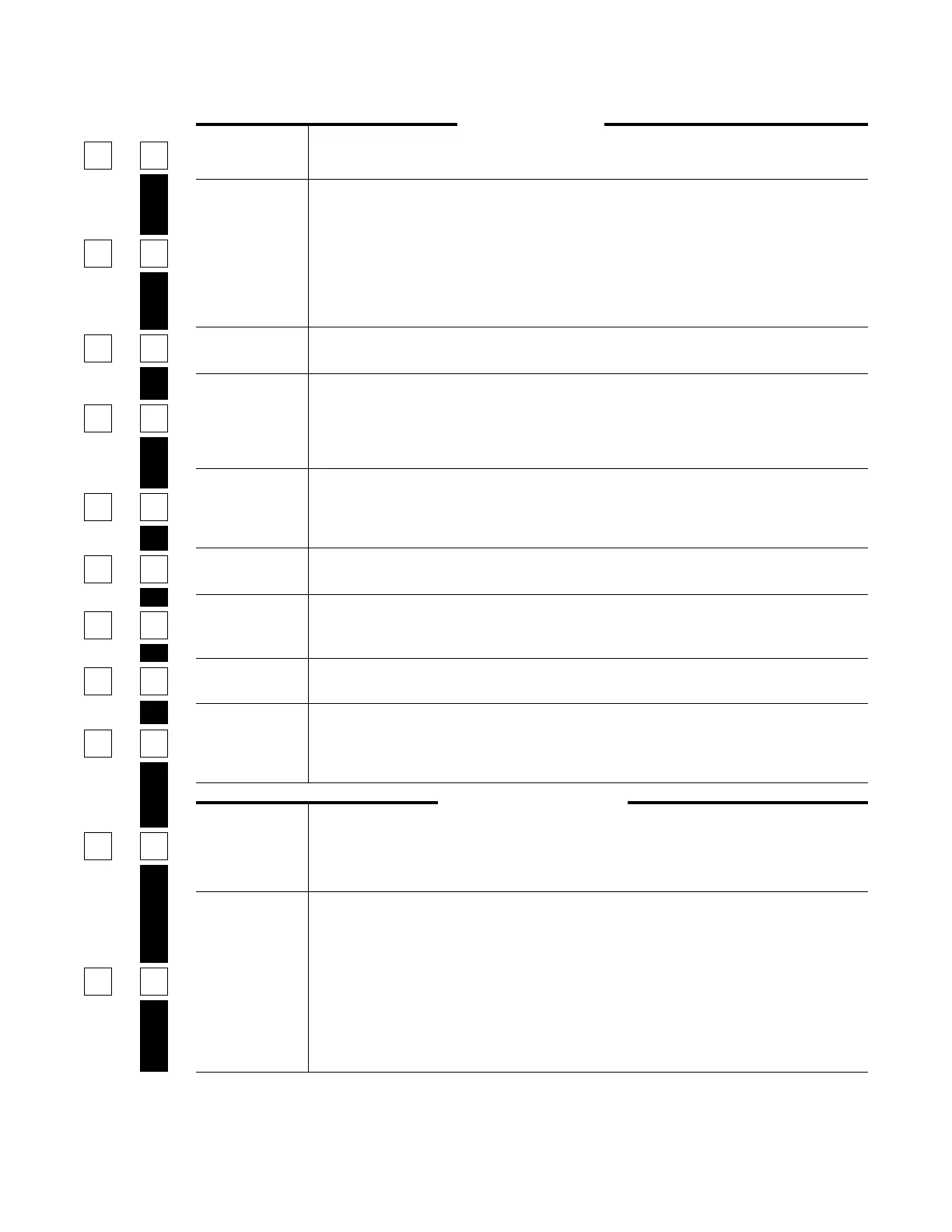

Semi-Annual Checks

! Check the levelness of the press. Press should by level in both the right-to-left and

front-to-back directions.

! Make certain press weight is being supported proportionately by all four feet and that

the bed is not being twisted.

! Evaluate general condition of the press and accessory equipment. Repair or replace

as necessary.

! Check major frame components (not previously inspected) for cracks, broken sections,

and worn parts.

! Check press for missing or broken accessory items.

! Check press foundation. Replace foundations that are broken, sinking, uneven or

loose.

! Check appearance of press. Repaint or clean thoroughly if necessary.

! Check floor area surrounding press. Floor should be clean and free from obstructions.

! Check aisleways to make certain they are clear and free from protruding objects.

I - 5

Bolster Plate

Clutch

Assembly

Cap Screws

and Fasteners

Power Slide

Adj. Parts

(If Furnished)

Knockout

Parts

Inclining

Mechanism

Motor Sheave

& Flywheel

V-Belts

Timing Belts

and Sheaves

(If Applicable)

Levelness

General

Condition of

Press and

Installation

Satisfactory

Unsatisfactory

Loading...

Loading...