13. While an assistant maintains pressure on the

slide, check clearance between the slide and the

untightened gib. Total gib clearance should not

exceed 0.003” to 0.004” (0.076 to 0.101 mm).

14. If gib clearance is satisfactory, relieve pressure on

the slide and tighten gib mounting bolts and lock

adjusting screws. If gibs require adjustment,

adjust the gibs following the procedure listed

under “To Adjust Gib Clearance,” page F-3.

15. When gib clearance is set, reinstall any covers

previously removed and tighten their associated

mounting screws securely.

F - 11

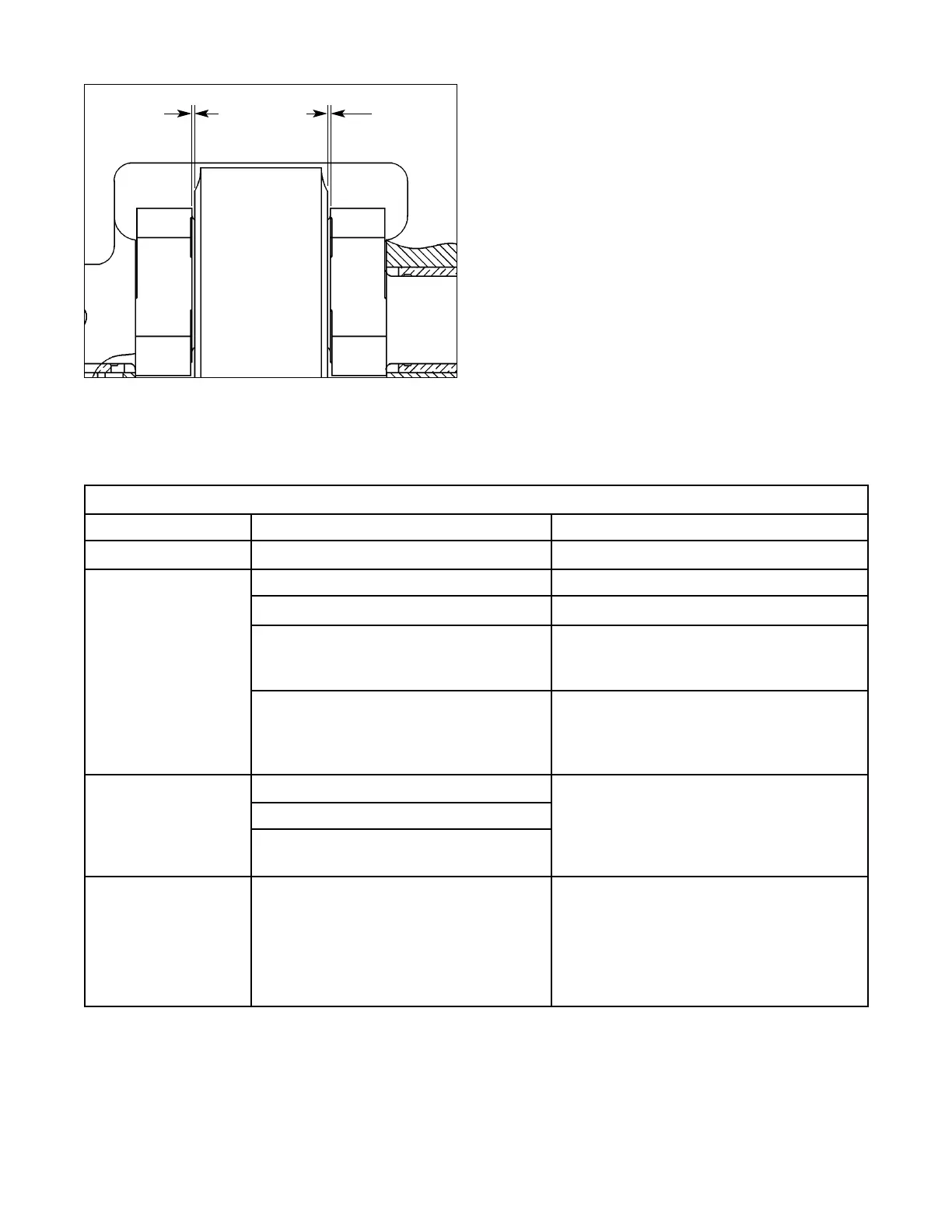

.03”

.03”

Figure 11F. Checking connection to crankshaft clearance.

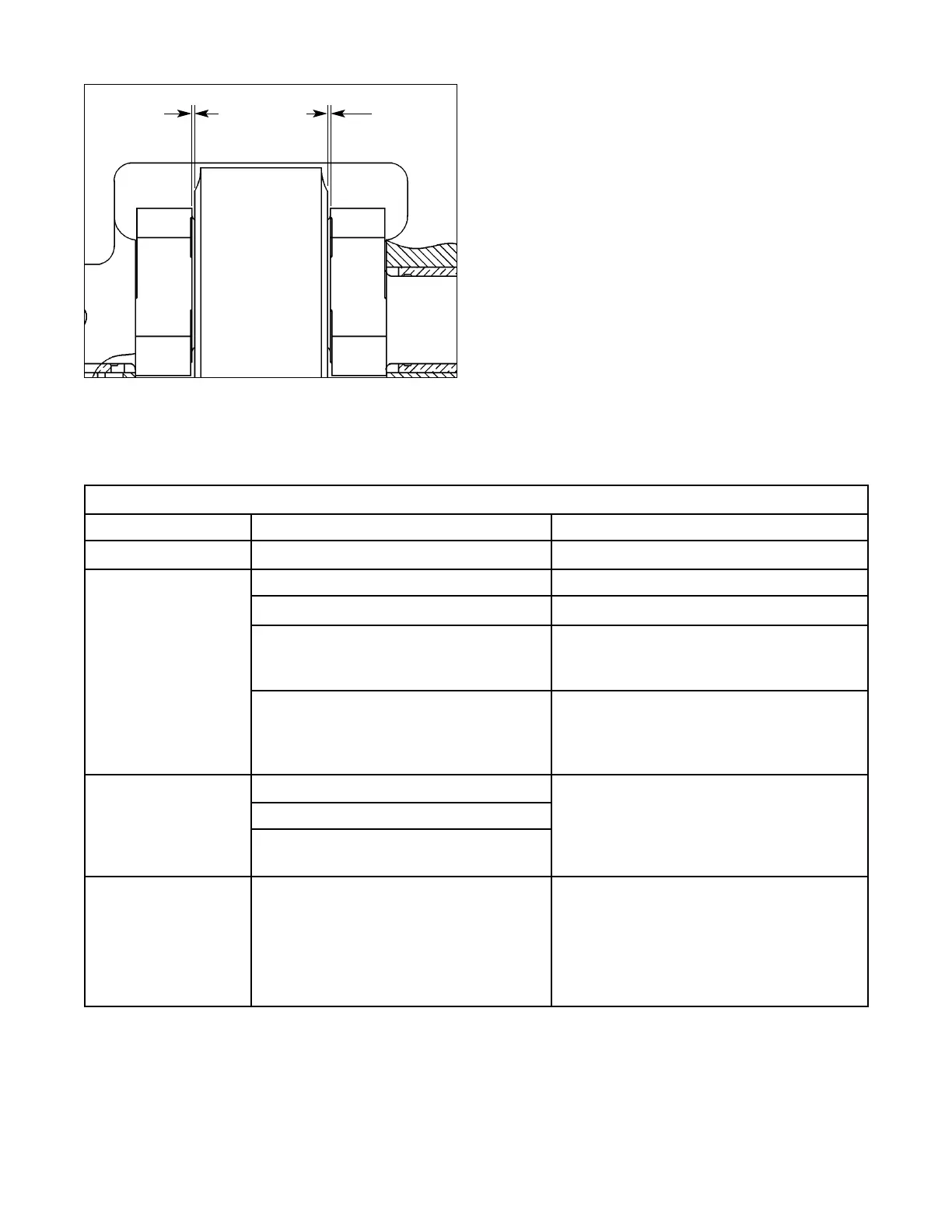

Factors Affecting Parallelism And Vertical Movement

DUE TO POSSIBLE CAUSE CORRECTION

Frame distorted. 1. Press not level (in twist). Level press carefully.

Gibs not adjusted

properly or gibs

are damaged.

1. Sliding surfaces worn due to usage. Set gibs as explained on page F-2.

2. Improper setting of gibs. Set gibs as explained on page F-2.

3. Gibs damaged (probably due to

lack of oil).

Repair or replace gib and wear plate, if

necessary. (Problem cannot be

corrected by adjustment.)

4. Gibs damaged (due to excessive

counterbalance pressure).

Repair or replace gib and wear plate if

necessary. Make certain counterbal-

ance pressure is set properly to avoid

future damage.

Worn or damaged

bearings.

1. Normal wear.

Check bearing clearances. (See page

G-4.) Replace bushings if clearance is

excessive. Eliminate the overload or

off-center loading condition.

2. Overheating or lack of lubrication.

3. Overloading or frequent off-center

loading.

Slide adjusting

nuts not turning

equally.

1. Slide adjustment bevel gears loose

on shaft or cross shaft brackets

loose.

Check condition of slide adjusting cross

shaft and bevel gear assembly. Replace

keys and tighten the set screws or cap

screws as necessary. Make certain slide

parallelism is correct before locking

components in the final position.

Loading...

Loading...