102

9 MAINTENANCE AND INSPECTION

9.2 Periodic Inspection

9.2 Periodic Inspection

This section describes items that must be inspected one or two times every six months to one year. When the equipment has

been relocated or modified, or cable laying has been changed, inspect the module for the items.

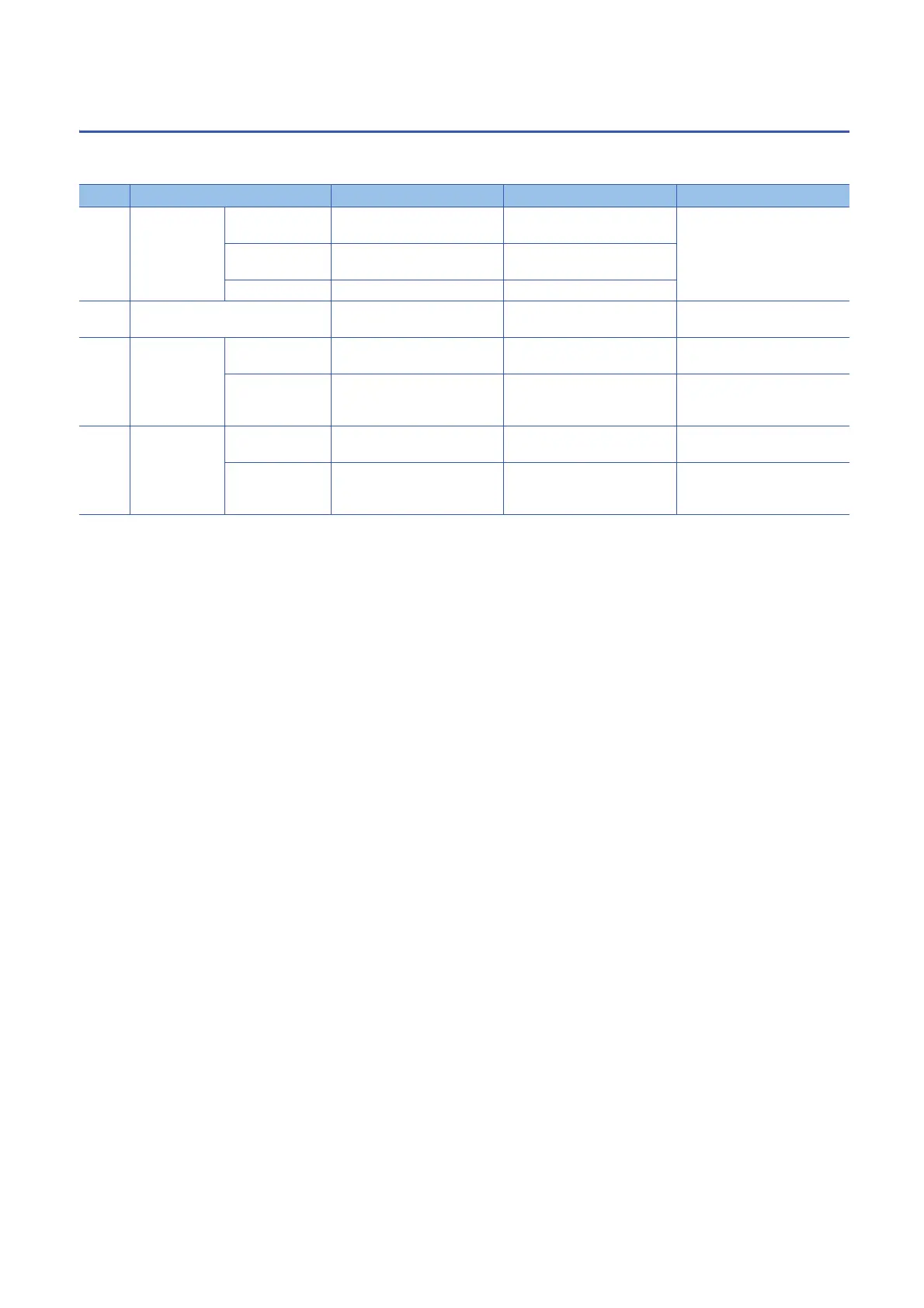

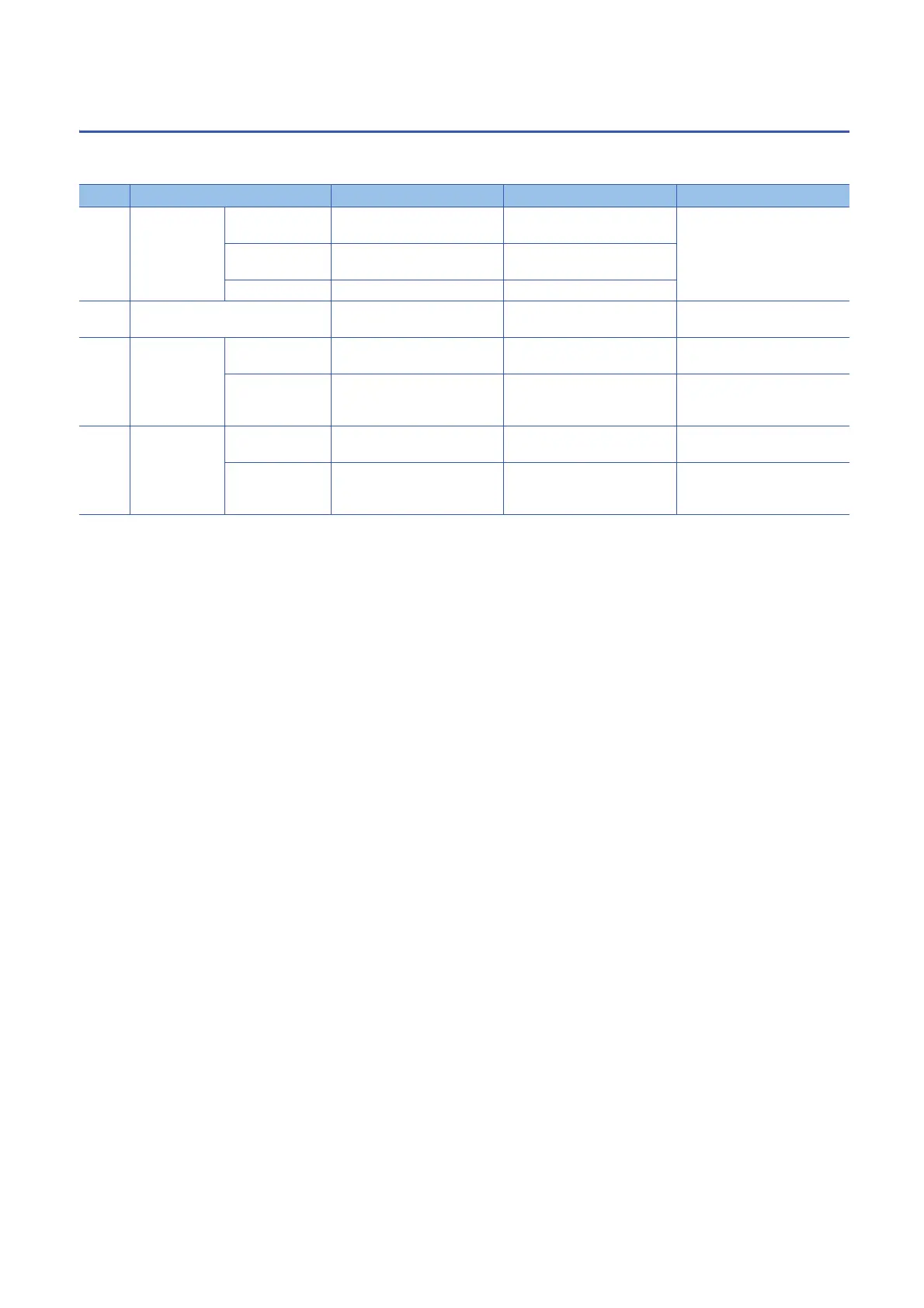

Item Inspection item Inspection method Judgment criterion Corrective action

1 Environment Ambient

temperature

Measure the temperature by

using a thermometer.

0 to 55 Create the environment that

satisfies the judgment criterion.

Ambient humidity Measure the humidity by using a

hygrometer.

5 to 95%RH

Atmosphere Measure corrosive gases. No corrosive gases

2 Power supply voltage check Measure the voltage across

24VDC terminals.

20.4 to 28.8VDC Change the supply power.

3 Installation Mounting status on

a DIN rail

Check for a rattling noise of the

safety remote I/O module.

The safety remote I/O module

does not rattle.

Remount the safety remote I/O

module on the DIN rail securely.

Terminal block

condition

Check for attachment of dirt and

foreign matters.

Dirt and foreign matters must not

be attached to terminal blocks.

Remove dirt and foreign matters

from the terminal block and clean

it.

4 Connection

status

Terminal block

mounting screw

Check for the looseness of

terminal block mounting screws.

The terminal block mounting

screws must not be loose.

Retighten terminal block

mounting screws securely.

Clearance between

solderless

terminals

Check the clearance between

solderless terminals.

The proper clearance must be

provided between solderless

terminals.

Provide the proper clearance.

Loading...

Loading...