7Appendix

Ex-T control Appendix-691

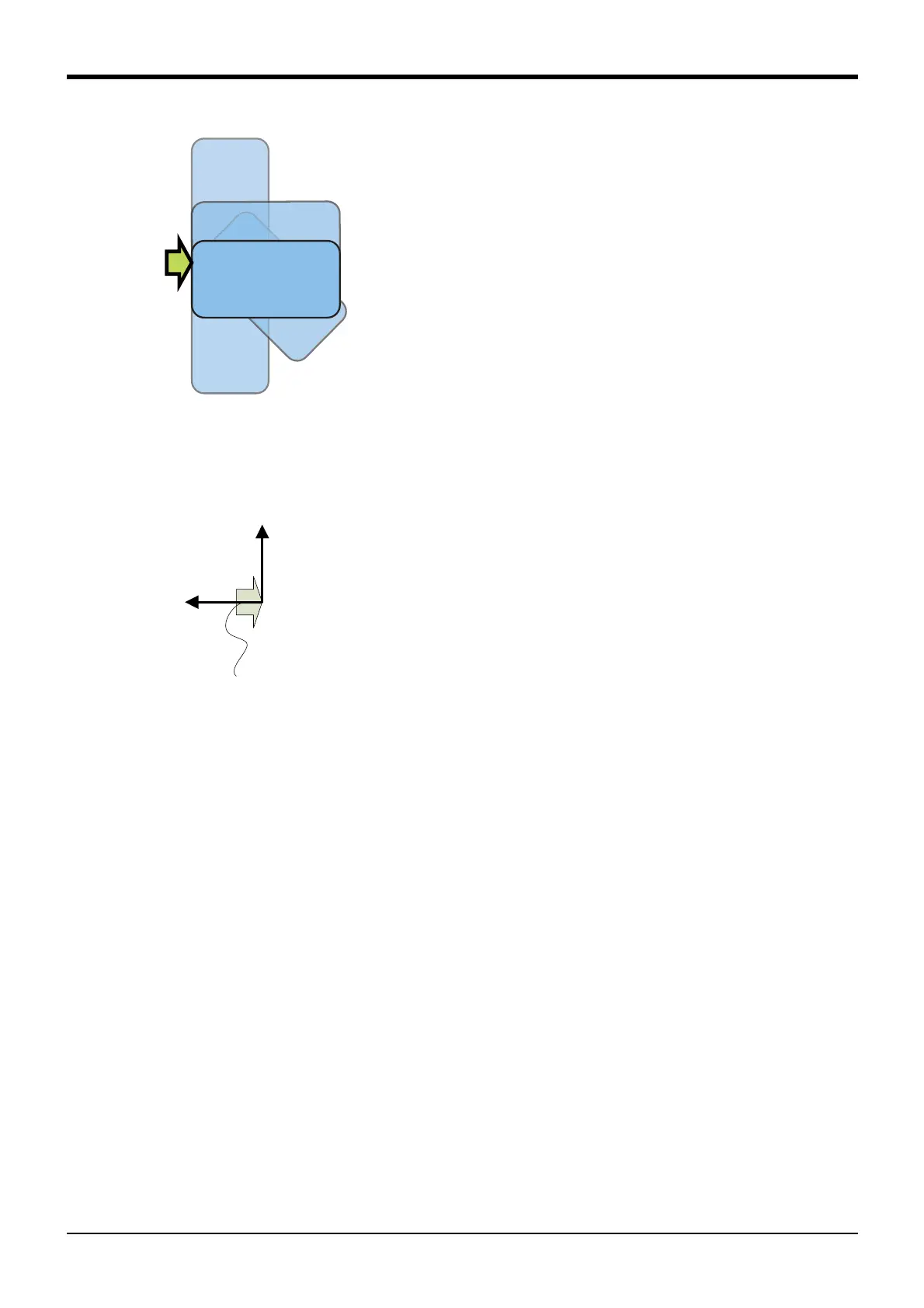

Fig.7-118:Operation example 2

■Step 1: Setting of the work coordinates (Ex-T coordinates)

Specify the work coordinates (Ex-T coordinates) so that the contact point between the processing tool and

the workpiece shown in the figure is used as the origin of the work coordinates (Ex-T coordinates). (On the

work coordinate 1 in this example)

In order to enable jog operation along this work coordinates system, set "1 (Ex-T jog mode)" in the parame-

ter WK1JOGMD.

■Step 2: Teaching of the positions

Let the robot actually hold the workpiece for teaching of the positions.

The positions <1> to <5> are taught in this example.

For teaching of the positions, performing jog feed of the robot in WORK jog (Ex-T jog) enables jog feed

along the processing tool.

■Step 3: Creation of the program

Create the MELFA-BASIC V program.

(Some of the actual necessary operations such as workpiece holding movement and input/output of signals

are omitted in this example.)

[Example program]

Mov P001 ’ Moves to the position <1>.

Dly 0.5

Spd 50 ’ Sets the processing speed (workpiece moving speed) to 50 mm/sec.

EMvs 1, P002 ’ Moves to the target position <2> along the work coordinate 1 by Ex-T

linear interpolation.

EMvr 1, P002,P003,P004 ’ Moves to the target position <4> from position <2> via position <3>

along the work coordinate 1 by Ex-T circular arc interpolation.

EMvs 1, P005 ’ Moves to the target position <5> along the work coordinate 1 by Ex-T

linear interpolation.

:

In this example, the teaching positions are five. More teaching positions are required depending on the

actual workpiece shape or processing operations. Change the program accordingly.

Loading...

Loading...