-

291

-

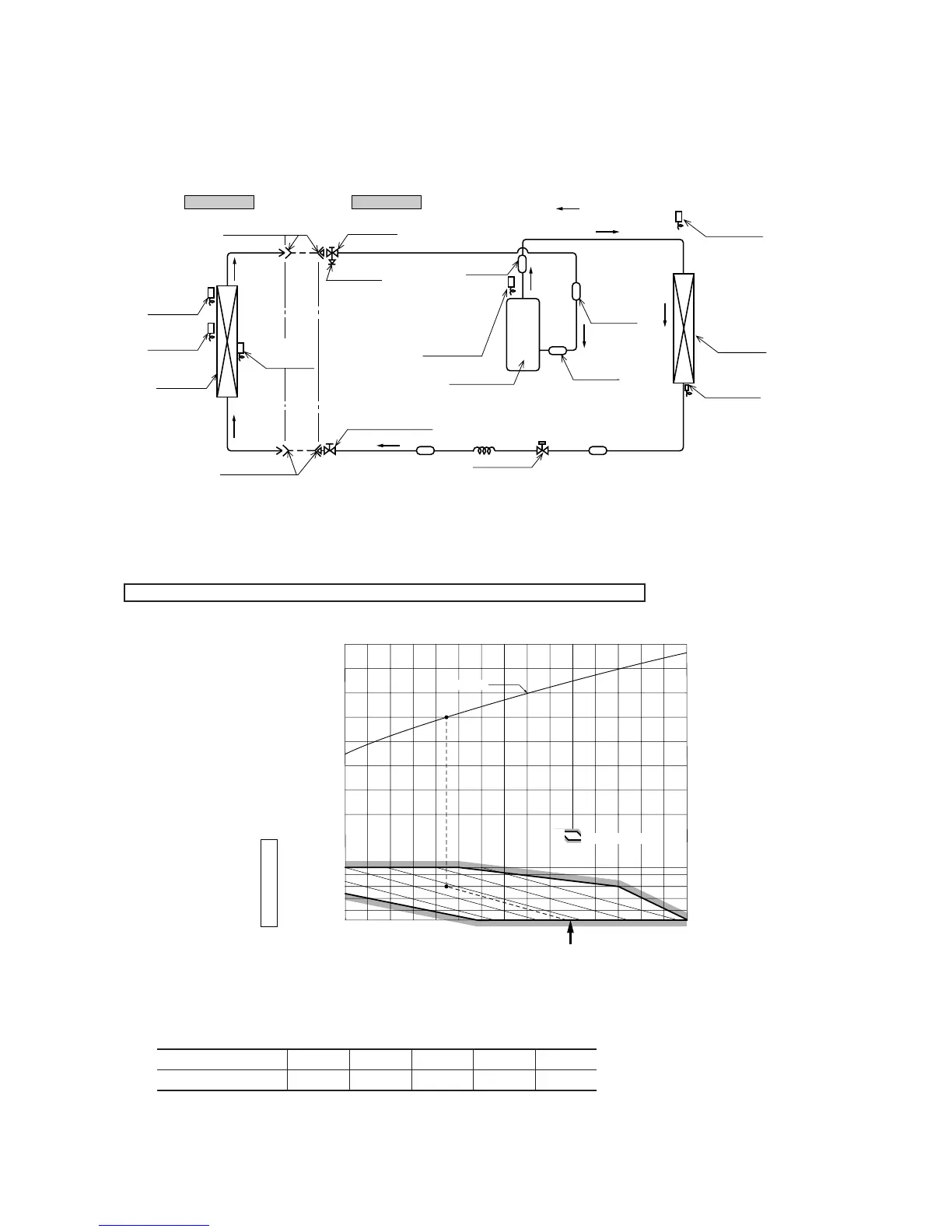

Outdoor unitIndoor unit

Room temp.

sensor

Humidity

sensor

Heat

exchanger

Flare connecting

Heat

exchanger

sensor

Piping

(Liquid)

ø

6.35

Piping

(Gas)

63:

ø

12.7

71:

ø

15.88

Check joint

Service valve (Liquid)

Flare connecting

Discharge pipe

temp. sensor

Cooling cycle

Muffler

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube

Strainer

Strainer

(71 model only)

accumulator

Sub

Accumulator

Service valve

(Gas)

Electronic

expansion valve

Models SRK63CE-S1, 71CE-S1

( )

(4) Piping system

(5) Selection chart

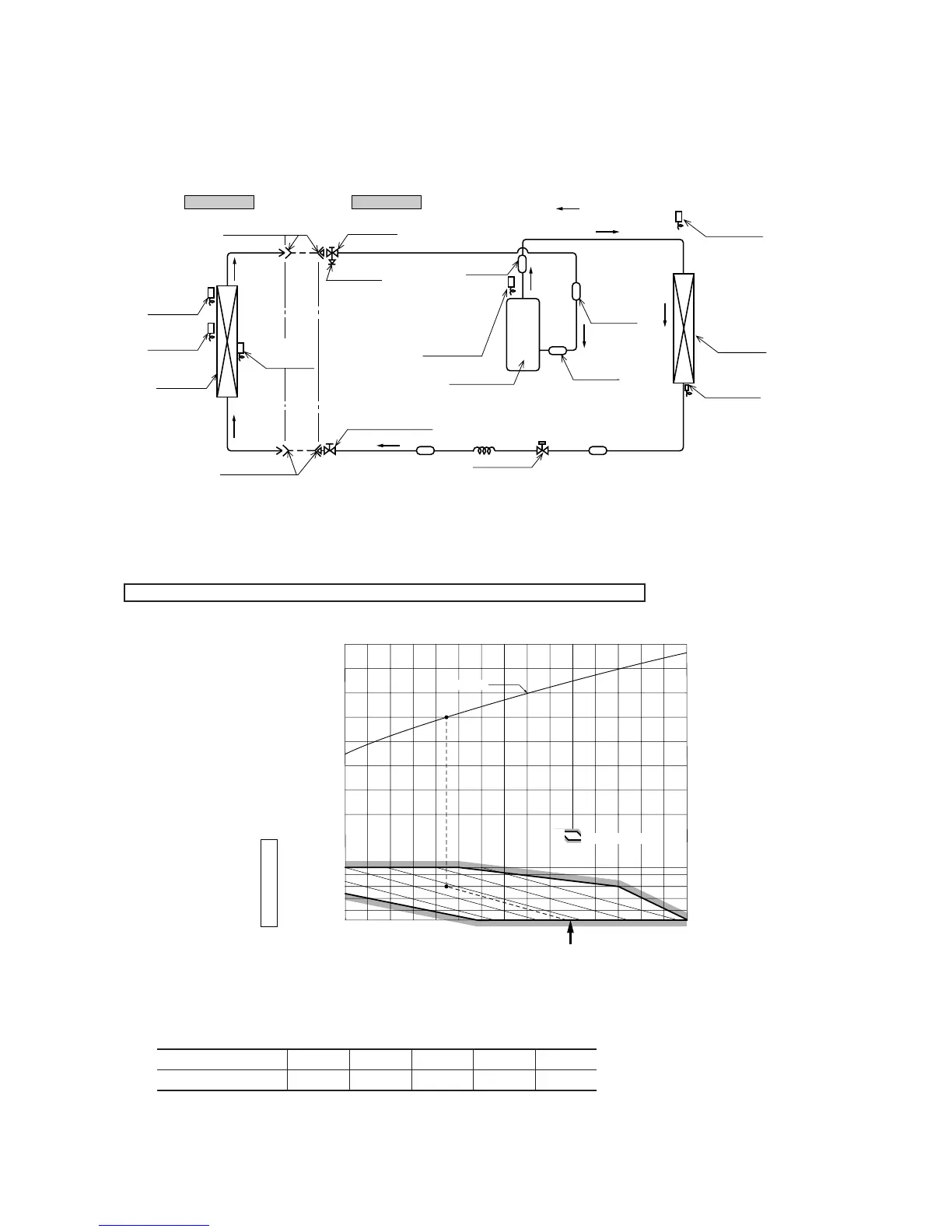

Correct the cooling capacity in accordance with the conditions as follows. The net cooling capacity can be obtained in the following

way.

Net capacity = Capacity shown on specification ✕ Correction factors as follows.

(a) Coefficient of cooling capacity in relation to temperatures

(2) Correction of cooling capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling capacity in relation to the one way piping length between the indoor and outdoor units.

16 18 20 22 24

ISO-T1 Standard ConditionIndoor air W.B. temperature ˚C W.B.

Applicable range

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Cooling

Coefficient of cooling &

Heating capacity in

relation to temperature

Cooling operation

Outdoor air D.B.

temperature

˚C D.B.

21

25

30

35

40

43

Piping length [m]

Cooling

7

1.0

10

0.99

15

0.975

20

0.965

25

0.95

Loading...

Loading...