8.

MAINTENANCE

AND

INSPECTION

/MELSEC-A

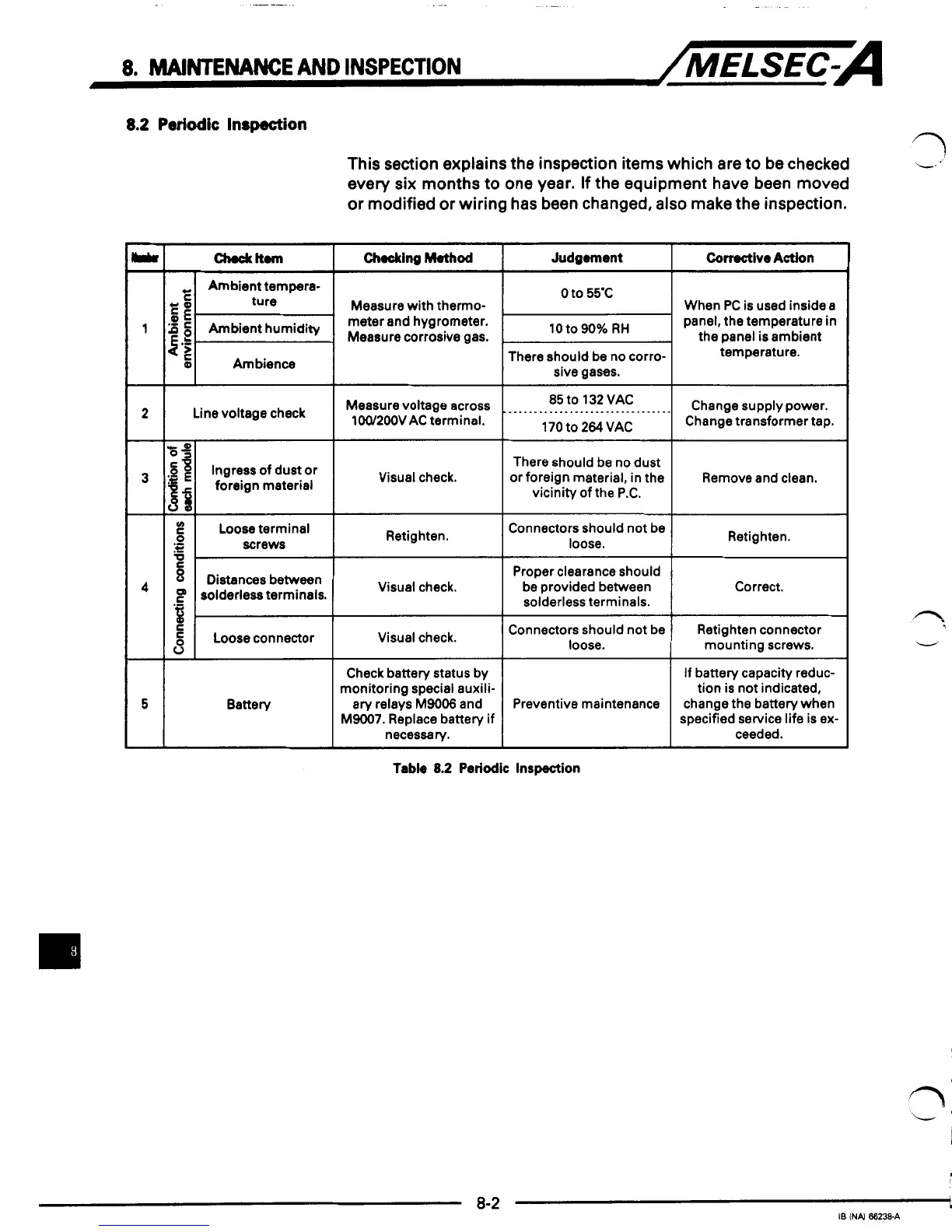

8.2

Periodic

Inspection

This section explains the inspection items which are to be checked

every

six

months to one year. If the equipment have been moved

or modified or wiring has been changed, also make the inspection.

2

-

3

4

5

-

ch.dr

km

Chocking

Mahod

-1

Ambient tempera-

Measure with thermo-

Measure corrosive gas.

meter and hygrometer.

E

'E

81

Ambience

I

Line voltage check

Measure voltage across

lW200VAC terminal.

foreign material

Visual check.

g

I

Looseterminal

.-

I

Retighten.

-

screws

Visual check,

.-

Y

6:

,Q

2

Loose connector Visual check.

Check battery status by

monitoring special auxili-

M9007. Replace battery if

Battery ary relays

M9006

and

Judgement

Comctiw

Action

0

to 55'C

When PC is used inside

a

panel, the temperature in

the panel is ambient

There should be no corro- temperature.

sive gases.

85 to 132 VAC

170 to

264

VAC

...............................

Change supply power.

Change transformer tap.

There should be no dust

or foreign material, in the

vicinity of the P.C.

Remove and clean.

Connectors should not be

loose.

Retighten.

Proper clearance should

be provided between

solderless terminals.

Connectors should not be

loose.

Preventive maintenance

Correct.

Retighten connector

mounting screws.

If battery capacity reduc-

tion

is

not indicated,

change the battery when

specified service life is ex-

ceeded.

~~ ~~~ ~ ~~

Table

8.2

Periodic

Inspection

3

1

3

7

3

3

J

3

1

-1

W

1

1

3

1

8-2

IB

INN

5823SA

Loading...

Loading...