8.

MAINTENANCE

AND

INSPECTION

/MELSEC-A

8.

MAINTENANCE

AND

INSPECTION

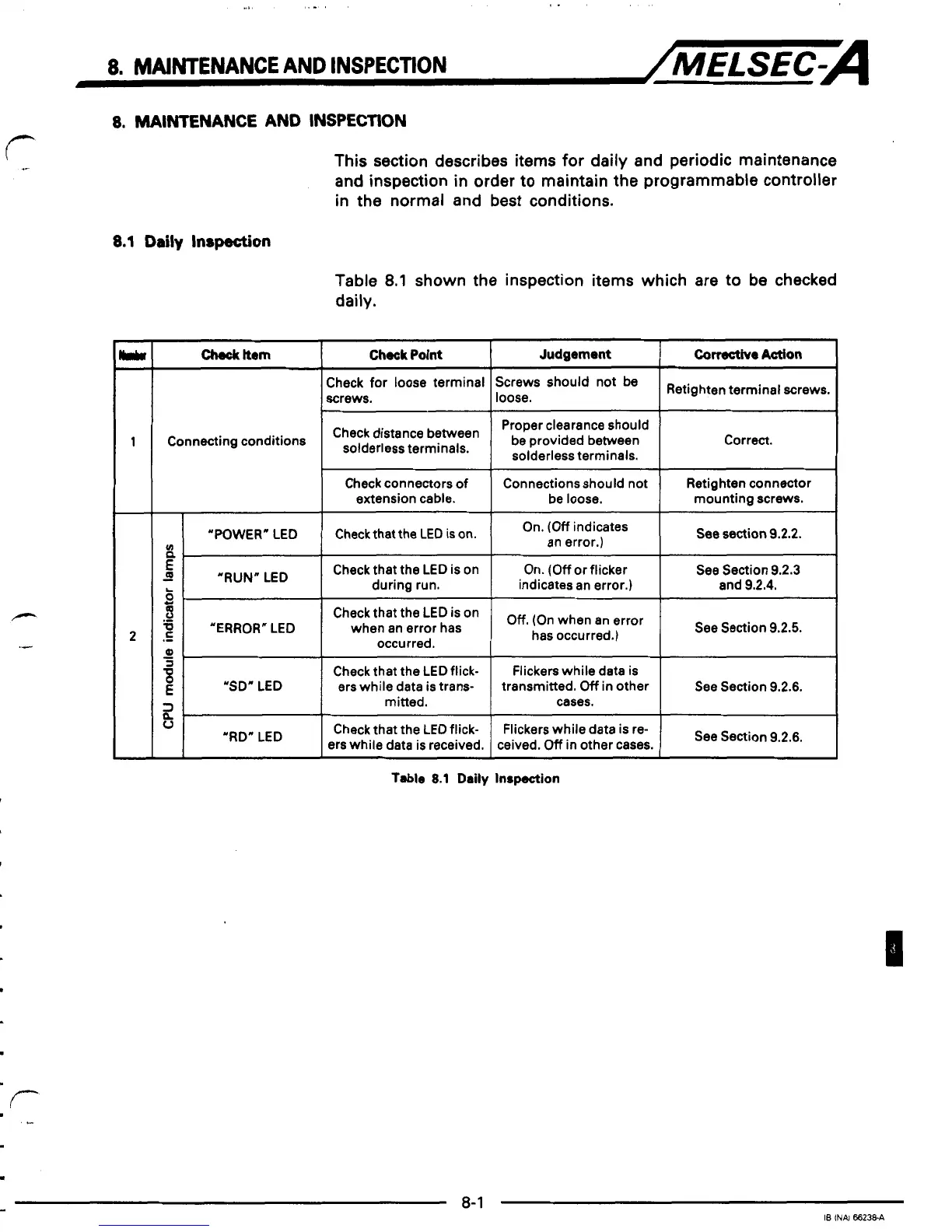

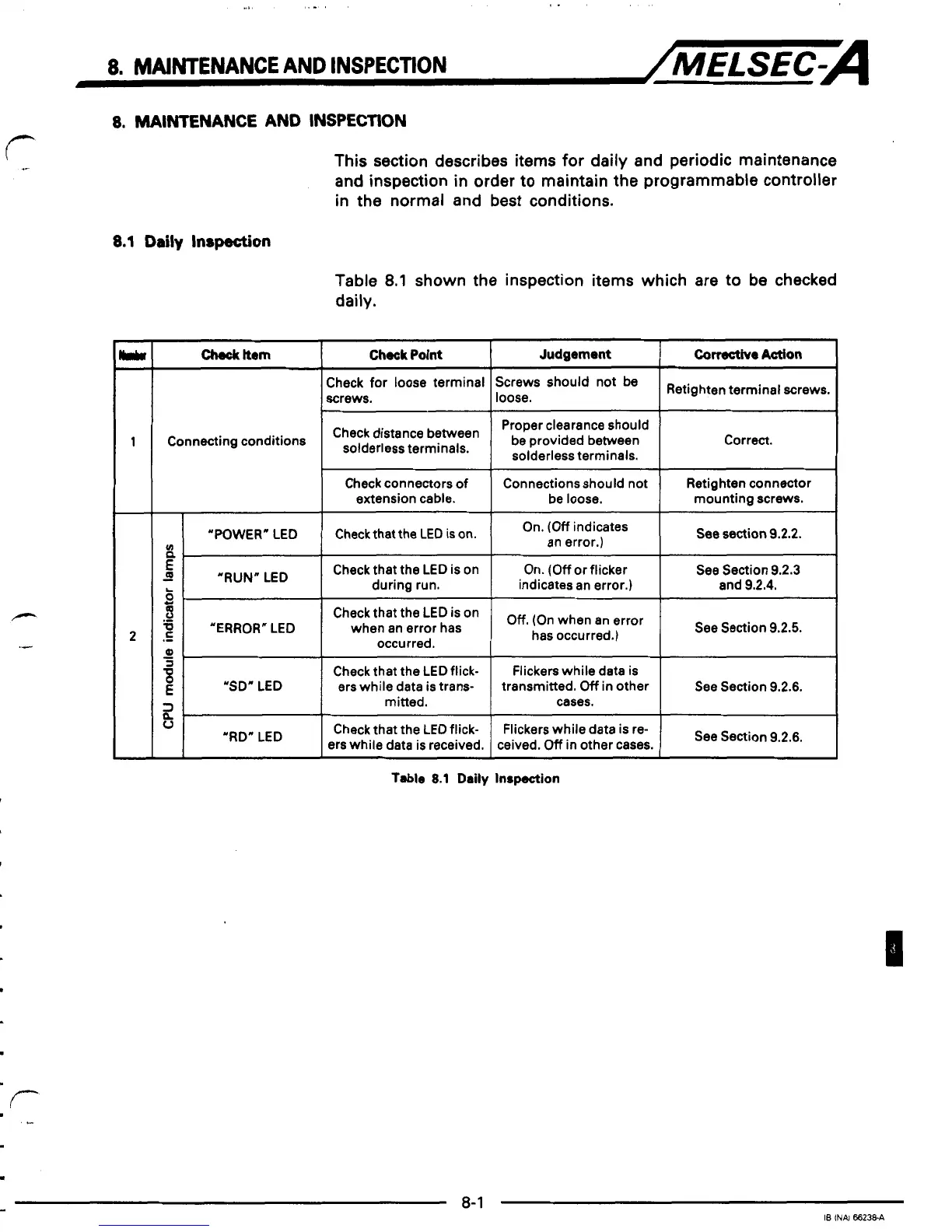

This section describes items for daily and periodic maintenance

and

inspection

in

order to maintain the programmable controller

in the normal and best conditions.

8.1

Daily

Inspection

Table

8.1

shown the inspection items which are to be checked

daily.

2

-

Connecting conditions

"POWER" LED

"RUN"

LED

'ERROR" LED

.-

-

'RD" LED

Check

Point

Corrective

Action

Judgement

I

Check for loose terminal

Screws should not be

Retighten

terminalscrews.

screws.

loose.

I

Check distance between

be

provided

Proper clearance should

solderless terminals.

solderless terminals.

Correct.

Check connectors of

mounting screws.

be loose.

extension cable.

Retighten connector Connections should not

Check that

the

LED

is

on.

1

an

error.)

1

See

section

9.2.2.

On.

(Off

indicates

Check that the LED is on

I

On.

(Off

or flicker See Section

9.2.3

during run. indicates an error.) and

9.2.4.

I

Check that the LED

is

on

Off,

(On

when

an

error

when an error has

occurred.

has occurred.)

See Section

9.2.5.

Check that the LED flick-

cases. mitted.

See Section

9.2.6.

transmitted.

Off

in other ers while data

is

trans-

Flickers while data

is

Check that the LED flick-

Flickers while data is re-

ers while data is received. ceived.

Off

in other cases.

See Section

9.2.6.

I

Loading...

Loading...