MPI <6A1> -

On-vehicle Service

13A-193

ON-VEHICLE SERVICE

OXYGEN SENSOR CHECK

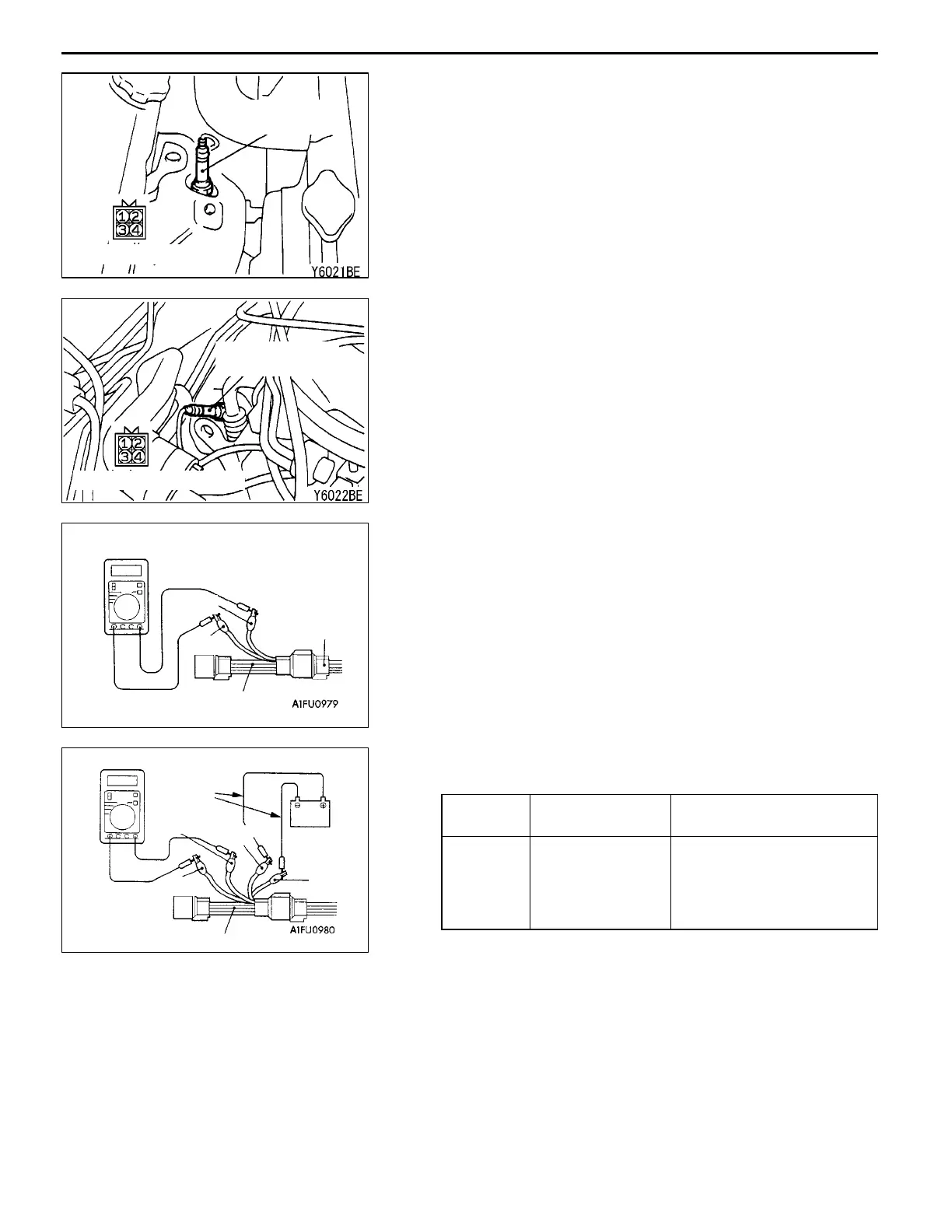

<Left bank oxygen sensor (front) and right bank

oxygen sensor (front)>

1. Disconnect the oxygen sensor connector and connect

the special tool (test harness) to the connector on the

oxygen sensor side.

2. Make sure that there is continuity (4.5 - 8.0

W

at 20

_

C)

between terminal 1 (red clip of special tool) and terminal

3 (blue clip of special tool) on the oxygen sensor connector.

3. If there is no continuity, replace the oxygen sensor.

4. Warm up the engine until engine coolant is 80

_

C or higher.

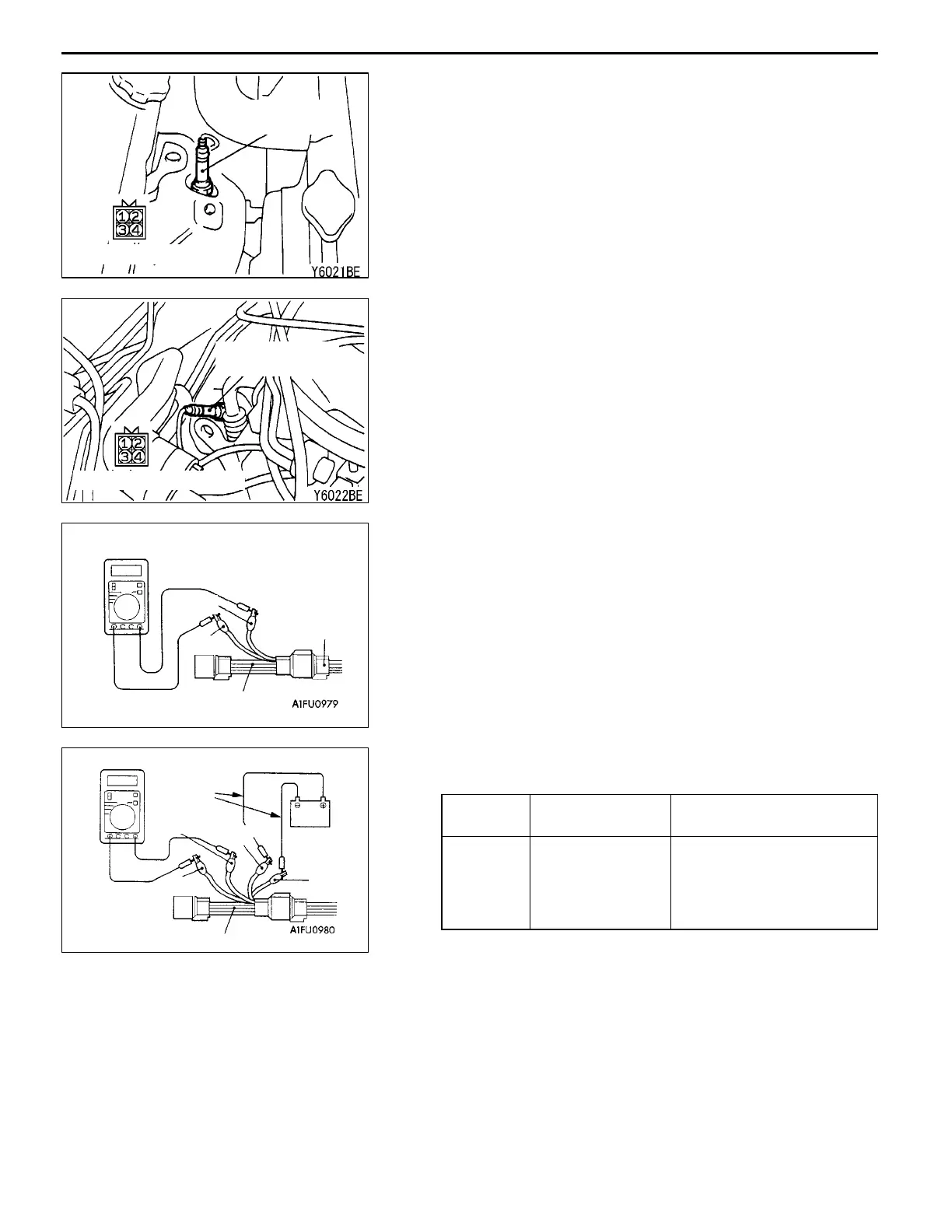

5. Use a jumper wire to connect terminal 1 (red clip) of

the oxygen sensor connector to the battery (+) terminal

and terminal 3 (blue clip) to the battery ( - ) terminal.

Caution

Be very careful when connecting the jumper wire;

incorrect connection can damage the oxygen sensor.

6. Connect a digital voltage meter between terminal 2 (black

clip) and terminal 4 (white clip).

7. While repeatedly racing the engine, measure the oxygen

sensor output voltage.

Standard value:

Engine Oxygen sensor

output voltage

Remarks

When

racing the

engine

0.6 - 1.0 V If you make the air/fuel ratio

rich by racing the engine

repeatedly, a normal oxy-

gen sensor will output a

voltage of 0.6 - 1.0 V.

8. If the sensor is defective, replace the oxygen sensor.

NOTE

For removal and installation of the oxygen sensor, refer

to GROUP 15 - Exhaust Pipe and Main Muffler.

Left bank oxygen

sensor (front)

Equipment side connector

Equipment side connector

Right bank oxygen

sensor (front)

Blue

Red

MD998464

Oxygen sen-

sor equipment

side connector

Jumper

wire

Black

Red

White

MD998464

Blue

Loading...

Loading...