BALANCER CHAIN <4B12>

ENGINE OVERHAUL

11B-49

INSTALLATION SERVICE POINTS

>>A<< LADDER FRAME INSTALLATION

CAUTION

Be sure to remove liquid gasket that has entered

mounting holes.

1. Completely remove liquid gasket adhering to the

cylinder block and ladder frame.

CAUTION

Sufficiently check that there is no residual oil on

the place where degreasing is performed. If fin

-

gerprints are left, do not touch it with bare hands

after the degreasing, since the oils from your fin

-

gers will harm the seal ability.

2. Degrease the surface where the liquid gasket is

applied and the contact surface between the

cylinder block and ladder frame.

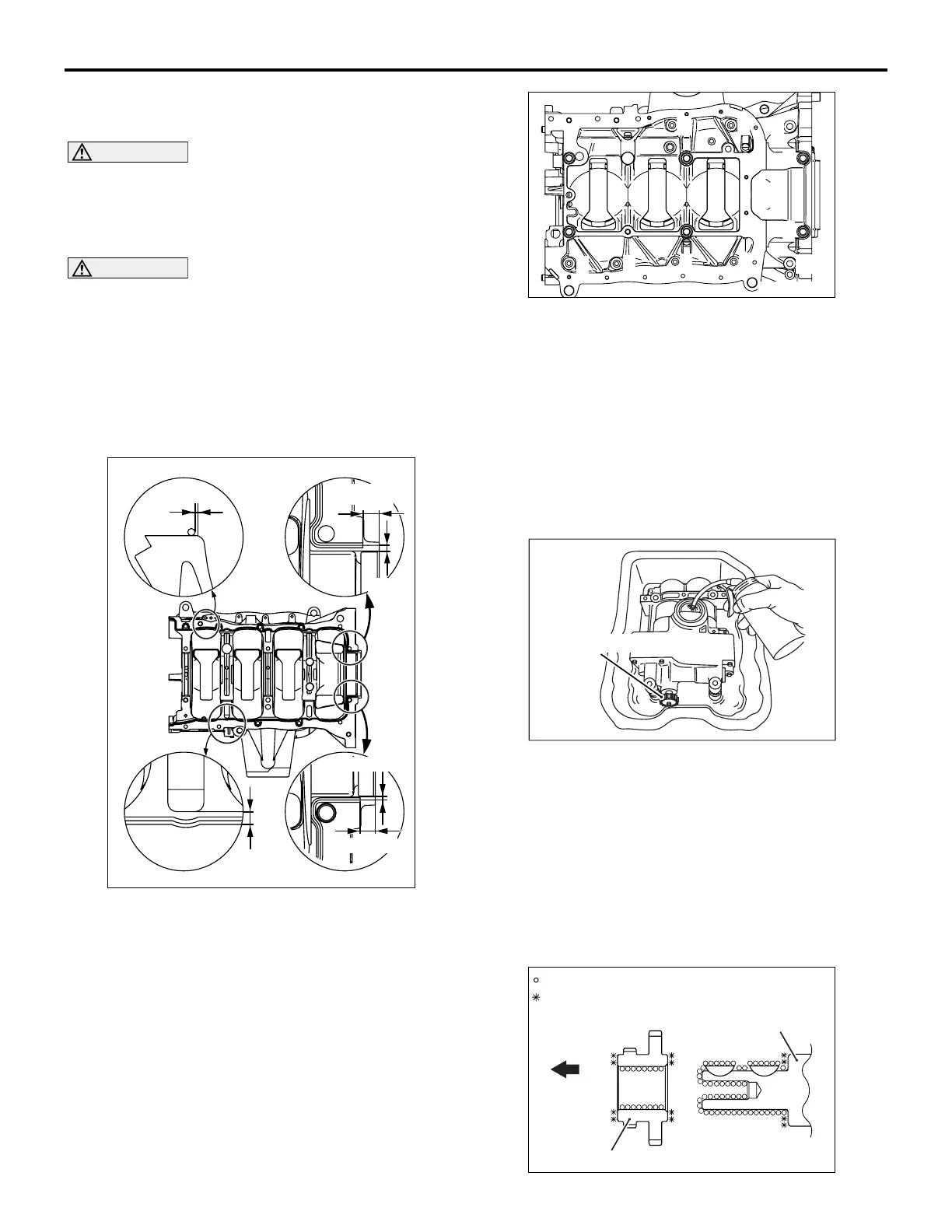

AK502868

1 mm

8.5 mm

3 mm

8.5 mm

1.75 mm

3 mm

AC

3. Squeeze liquid gasket of φ2.5 ± 0.5 mm in

thickness and apply it to the illustrated position of

the ladder frame.

Specified sealant:

ThreeBond 1217G or equivalent

AKB00722

AB

1

3

6

2

4

5

7

9

8

10

4. Tighten the ladder frame to the specified torque of

24

± 2 N⋅m in the order shown in the illustration.

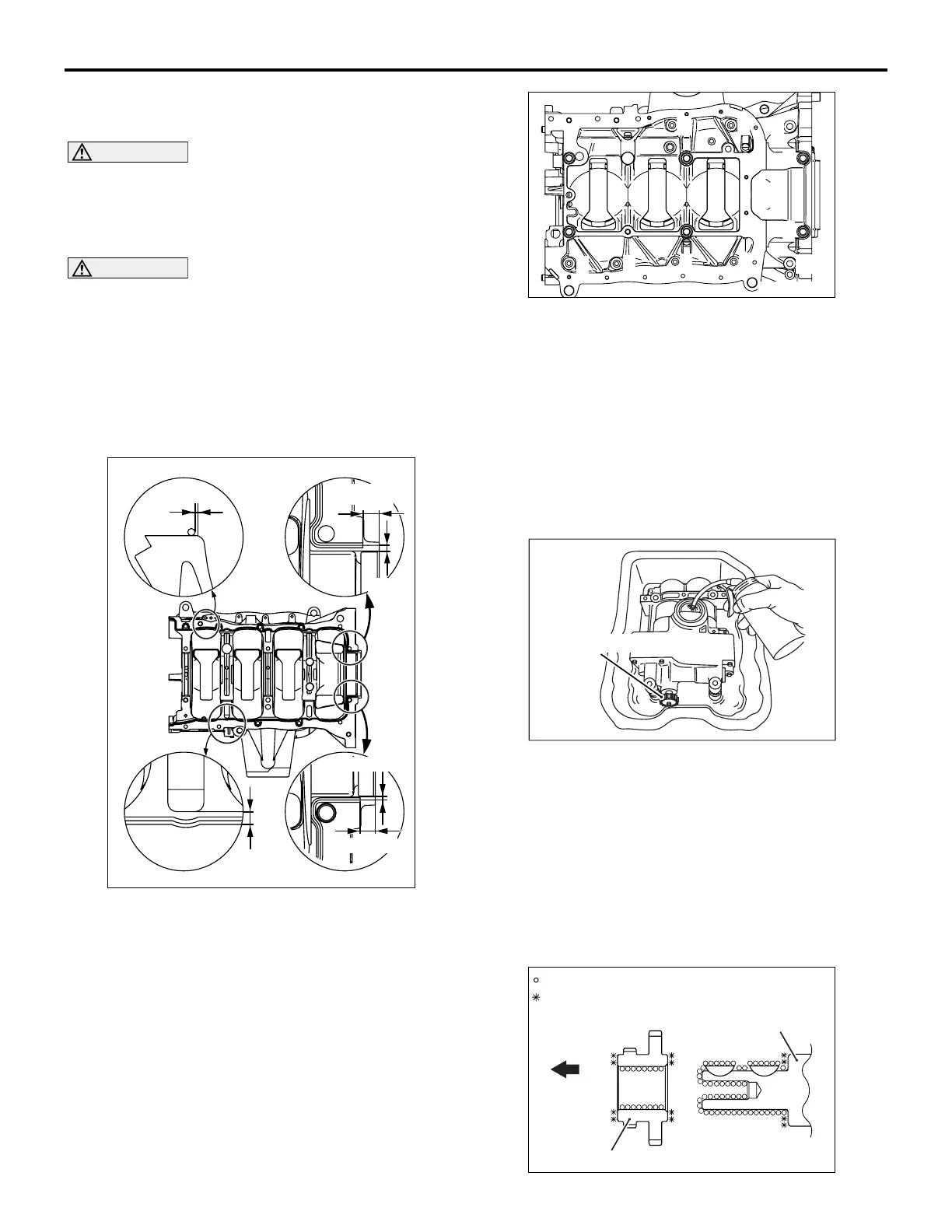

>>B<< CRANKSHAFT SPROCKET /

BALANCER CHAIN / BALANCER SHAFT

MODULE INSTALLATION

When the new balancer shaft module is installed,

supply oil to the oil pump and the balancer shaft

bearing in the balancer shaft module using the fol

-

lowing procedures.

AK503559

AC

Balancer shaft sprocket

a. Clean the inside of the removed oil pan. Put the

balancer shaft module carefully into the oil pan so

that the oil inlet can be upward.

b. Pour the engine oil so that the two-third of the

balancer module can be immersed.

c. Also, pour approximate 50 cc of engine oil from

the oil inlet.

d. By giving four clockwise rotations or more to the

balancer shaft sprocket, the oil is supplied to the

oil pump and the balancer shaft bearing.

AK603521

AE

Crankshaft sprocket

Crankshaft

Engine

front

: Wipe clean with a rag.

: Wipe clean with a rag and degrease.

Loading...

Loading...