ChaDter 6 Emissions control svstems

6-5

Carbon element

Air cleaner /

Purge control valve

Fuel check valve

Charcoal

I

II #

~.............,........, :.:.:,.,I

-Fuel vapor

-- - Purge air

I/L

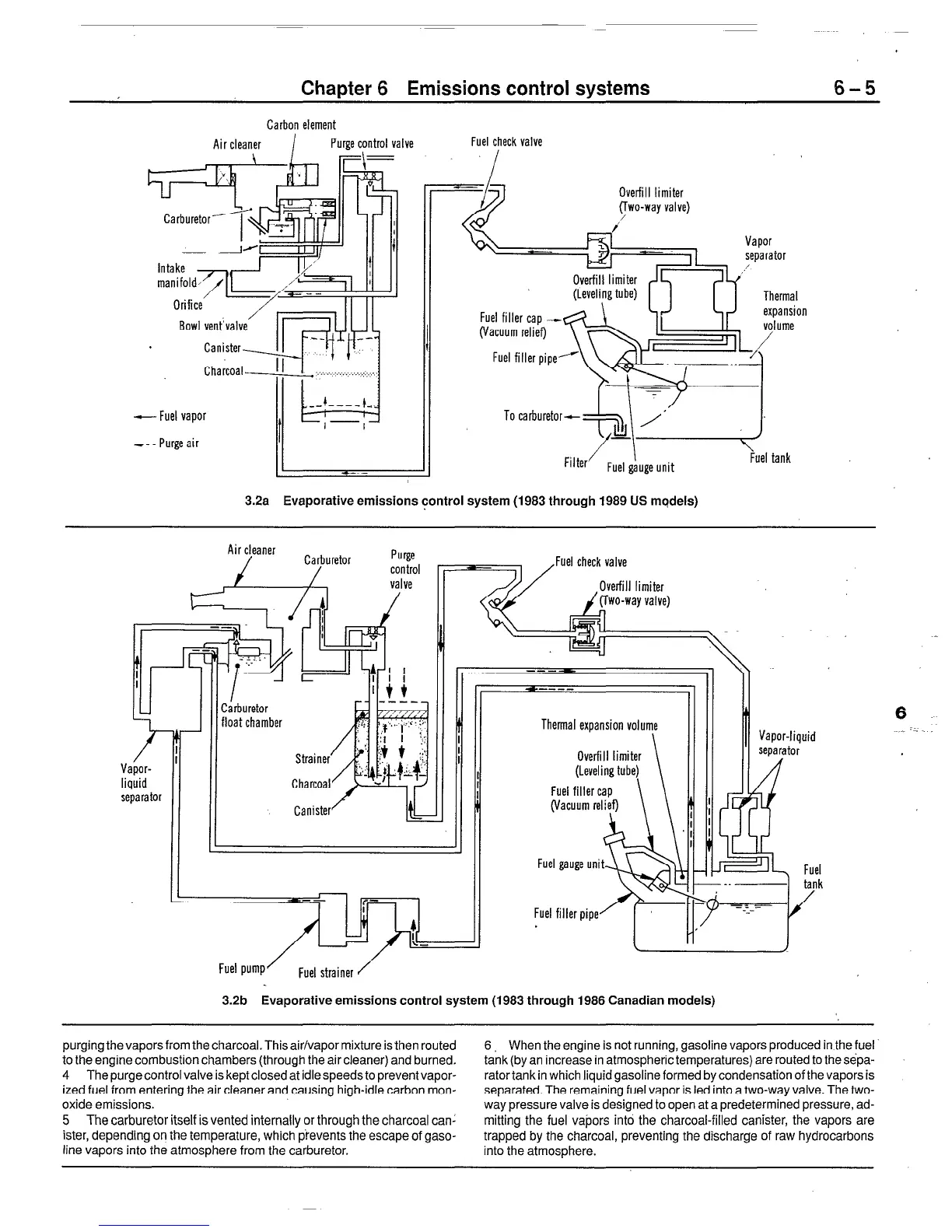

3.2a Evaporative emissions control system (1983 through 1989 US mqdels)

Air cleaner

/

Caguretor rrrm?,t,

Vapor-

liquid

separator

Carburetor

float chamber

Fuel filler cap

(Vacuum relic,‘)

\ \ #li I

I 1

6

Fuel pump’

Fuel strainer /

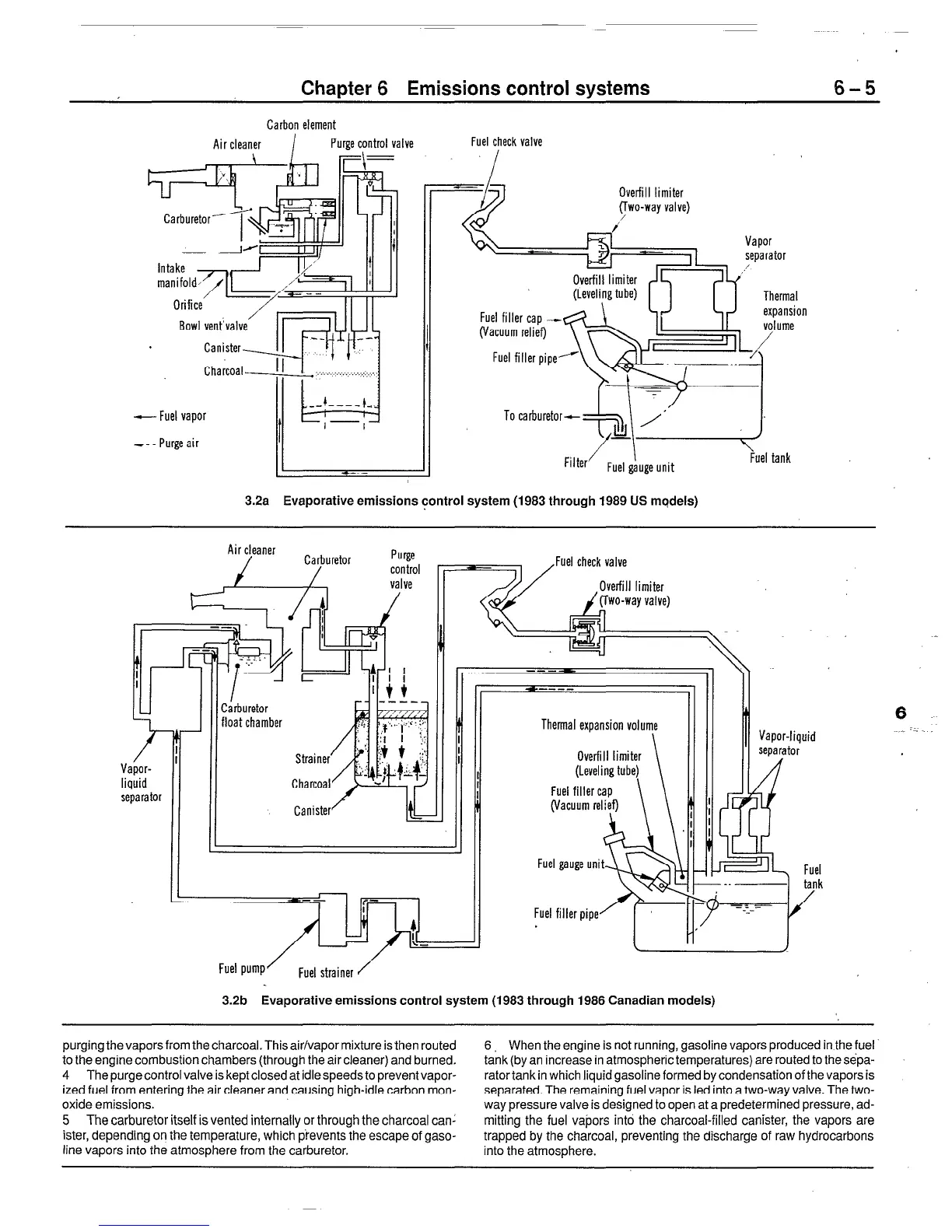

3.2b Evaporative emissions control system (1983 through 1986 Canadian models)

purging thevapors from the charcoal. This air/vapor mixture isthen routed 6 When the engine is not running, gasoline vapors produced in the fuel

to the engine combustion chambers (through the air cleaner) and burned.

tank (by an increase in atmospheric temperatures) are routed to the sepa-

4 The purge control valve is kept closed at idle speeds to prevent vapor-

rator tank in which liquid gasoline formed by condensation of the vapors is

ized fuel from entering the air cleaner and causing high-idle carbon mon- separated. The remaining fuel vapor is led into a two-way valve. The two-

oxide emissions. way pressure valve is designed to open at a predetermined pressure, ad-

5 The carburetor itself is vented internally or through the charcoal can- mitting the fuel vapors into the charcoal-filled canister, the vapors are

ister, depending on the temperature, which prevents the escape of gaso- trapped by the charcoal, preventing the discharge of raw hydrocarbons

line vapors into the atmosphere from the carburetor. into the atmosphere.

Loading...

Loading...