Air cleaner

Fuel iniector 1 1 (To-iniector) 11

,II

-

C--

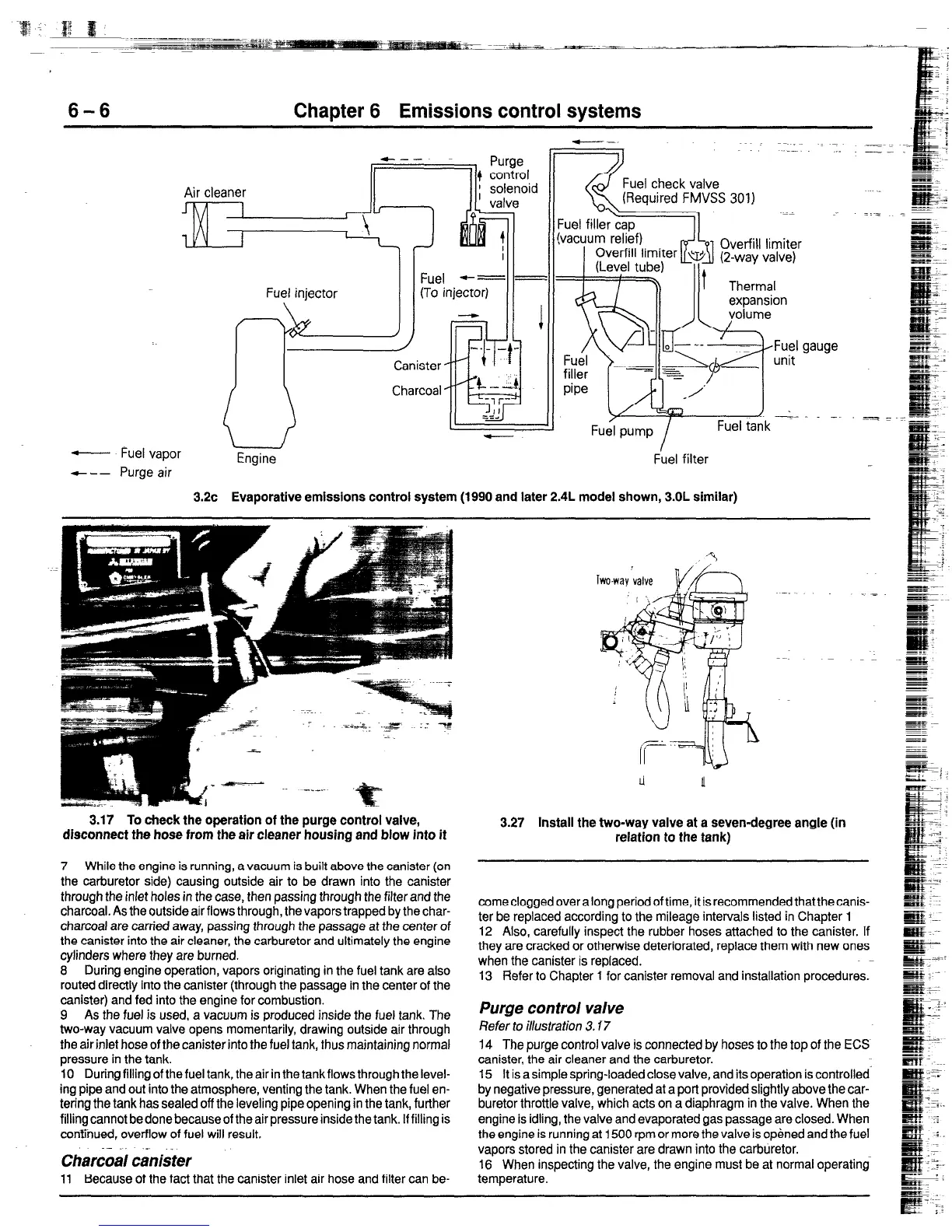

3.2~ Evaporative emissions control system (1990 and later 2.4L model shown, 3.OL similar)

Fuel vapor

Purge air

L’

--

‘1

Fuel tank

-

FUG pump

I

Fuel filter

3.17 To check the operation of the purge control valve,

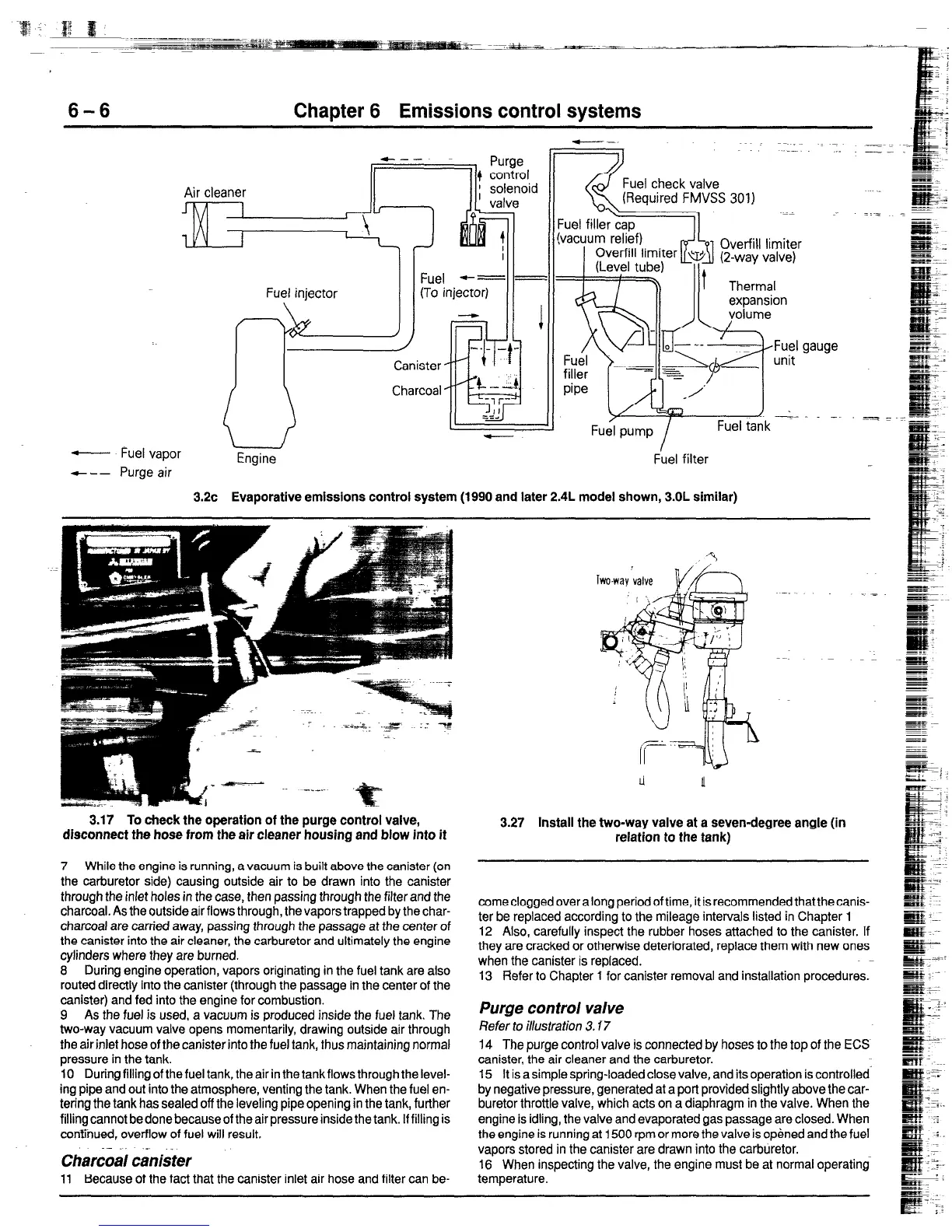

3.27

disconnect the hose from the air cleaner housing and blow into it

Install the two-way valve at a seven-degree angle (in

relation to the tank)

7 While the engine is running, avacuum is built above the canister (on

the carburetor side) causing outside air to be drawn into the canister

through the inlet holes in the case, then passing through the filter and the

charcoal. As the outside air flows through, the vapors trapped by the char-

charcoal are carried away, passing through the passage at the center of

the canister into the air cleaner, the carburetor and ultimately the engine

cylinders where they are burned.

8 During engine operation, vapors originating in the fuel tank are also

routed directly into the canister (through the passage in the center of the

canister) and fed into the engine for combustion.

9 As the fuel is used, a vacuum is produced inside the fuel tank. The

two-way vacuum valve opens momentarily, drawing outside air through

the air inlet hose of the canister into the fuel tank, thus maintaining normal

pressure in the tank.

10 Duringfillingof thefuel tank, theairin thetankflowsthrough the level-

ing pipe and out into the atmosphere, venting the tank. When the fuel en-

tering the tank has sealed off the leveling pipe opening in the tank, further

filling cannot be done because of the air pressure inside the tank. If filling is

confinued, overflow of fuel will result.

come clogged over a long period of time, it is recommended that the canis-

ter be replaced according to the mileage intervals listed in Chapter 1

12 Also, carefully inspect the rubber hoses attached to the canister. If

they are cracked or otherwise deteriorated, replace them with new ones

when the canister is replaced.

13 Refer to Chapter 1 for canister removal and installation procedures.

-- ._ ._

Charcoal canister

11 Because of the fact that the canister inlet air hose and filter can be-

Purge control valve

Refer to illustration 3.77

14 The purge control valve is connected by hoses to the top of the ECS

canister, the air cleaner and the carburetor.

15 It is a simple spring-loaded close valve, and its operation is controlled-

by negative pressure, generated at a port provided slightly above the car-

buretor throttle valve, which acts on a diaphragm in the valve. When the

engine is idling, the valve and evaporated gas passage are closed. When

the engine is running at 1500 rpm or more the valve is opened and the fuel

vapors stored in the canister are drawn into the carburetor.

16 When inspecting the valve, the engine must be at normal operating

temperature.

Loading...

Loading...