6-16 Chapter 6 Emissions control systems

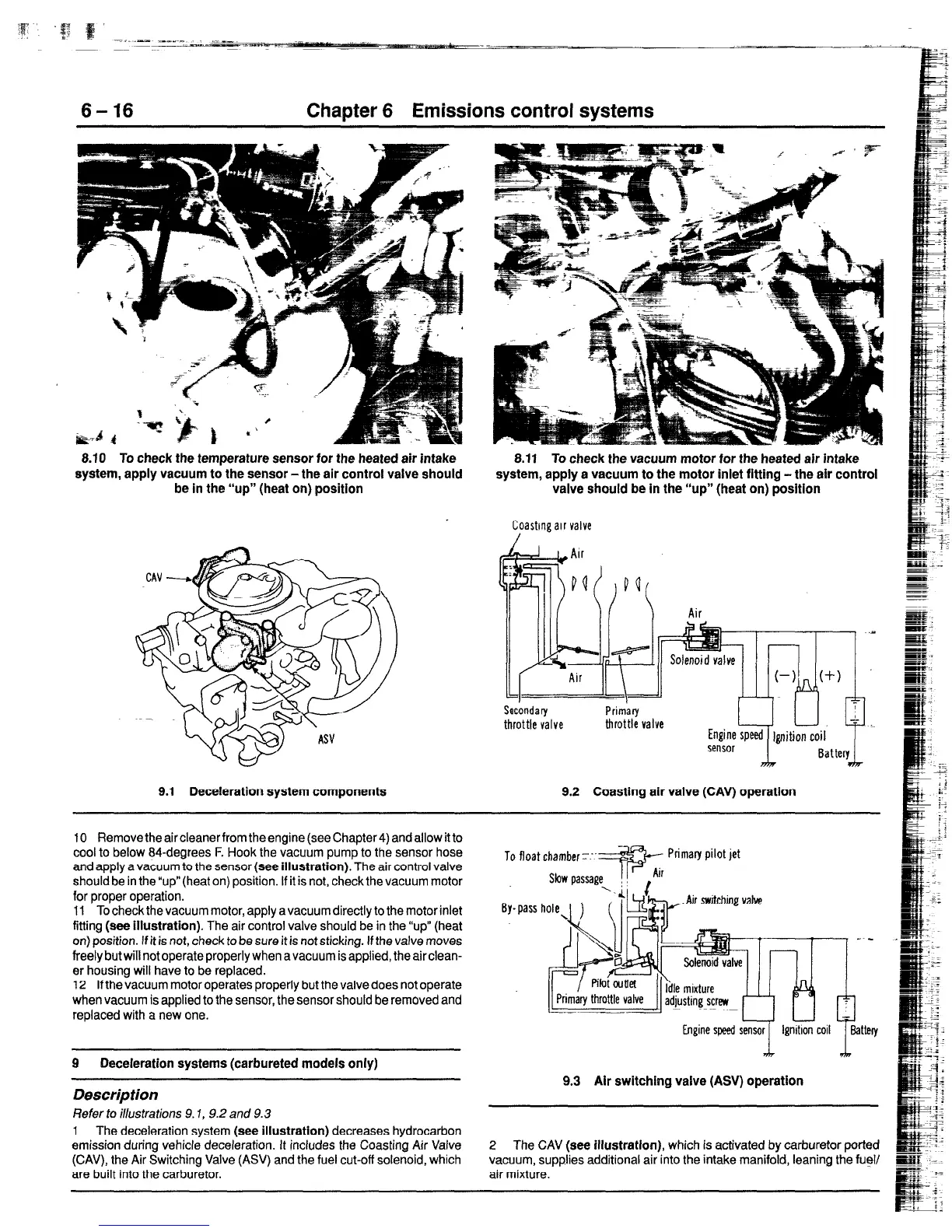

8.10 To check the temperature sensor for the heated air intake

system, apply vacuum to the sensor-the air control valve should

be in the “up” (heat on) position

9.1 Deceleration system components

8.11 To check the vacuum motor for the heated air intake

system, apply a vacuum to the motor inlet fitting -the air control

valve should be in the “up“ (heat on) position

Coasting air valve

/

9.2 Coasting air valve (CAV) operatlon

10 Remove the air cleaner from the engine (see Chapter 4) and allow it to

cool to below 84-degrees F. Hook the vacuum pump to the sensor hose

and apply a vacuum to the sensor

(see illustration).

The air control valve

should be in the “up” (heat on) position. If it is not, check the vacuum motor

for proper operation.

11 To check the vacuum motor, apply a vacuum directly to the motor inlet

fitting

(see illustration).

The air control valve should be in the “up” (heat

on) position. If it is not, check to be sure it is

not

sticking. If the valve moves

freely but wiIl not operate properly when a vacuum is applied, the air clean-

er housing will have to be replaced.

12 If the vacuum motor operates properly but the valve does not operate

when vacuum is applied to the sensor, the sensor should be removed

and

replaced with a new one.

To float chamber-:.

9

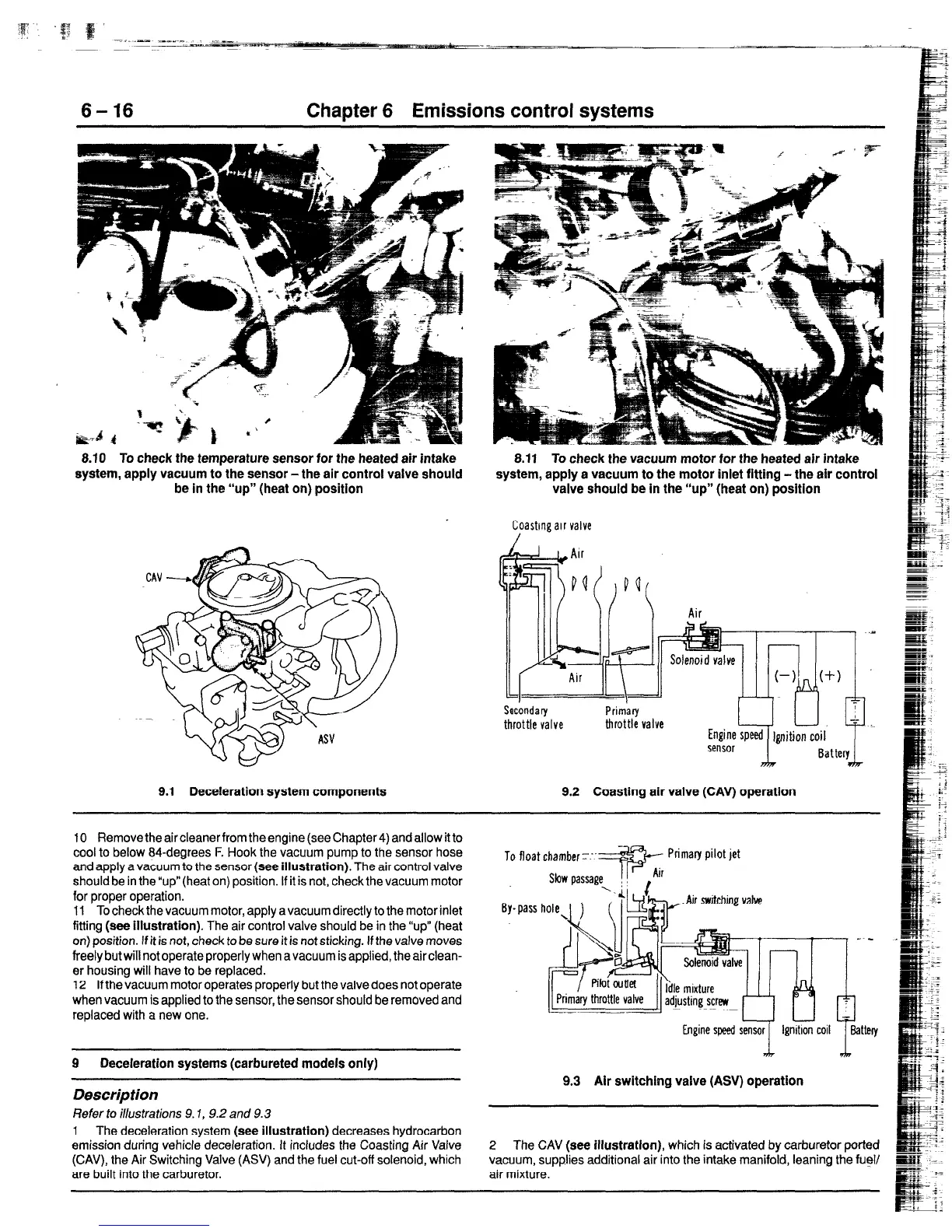

Deceleration systems (carbureted models only)

Description

Refer to illustrations 9.7, 9.2 and 9.3

1 The deceleration system

(see illustration)

decreases hydrocarbon

emission during vehicle deceleration. It includes the Coasting Air Valve

(CAV), the Air Switching Valve (AS/) and the fuel cut-off solenoid, which

are built into the carburetor.

9.3 Air switching valve (ASV) operation

2

The CAV

(see illustration),

which is activated by carburetor ported

vacuum, supplies additional air into the intake manifold, leaning the fuel/

air mixture.

Loading...

Loading...