Chapter 4 Fuel and exhaust systems ’

4-21

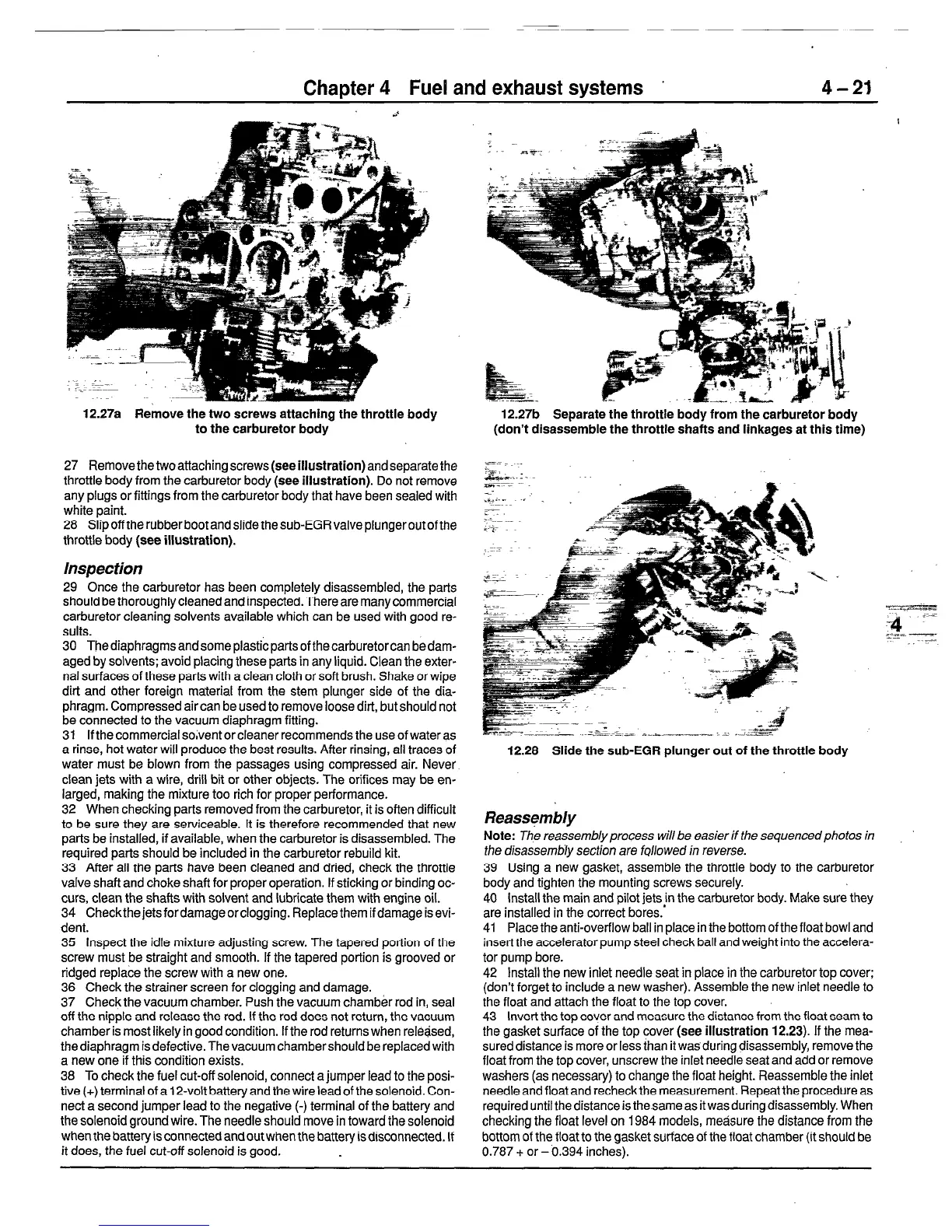

12.27a Remove the two screws attaching the throttle body

to the carburetor body

27 Remove thetwo attaching screws (see illustration) and separate the

throttle body from the carburetor body (see illustration). Do not remove

any plugs or fittings from the carburetor body that have been sealed with

white paint.

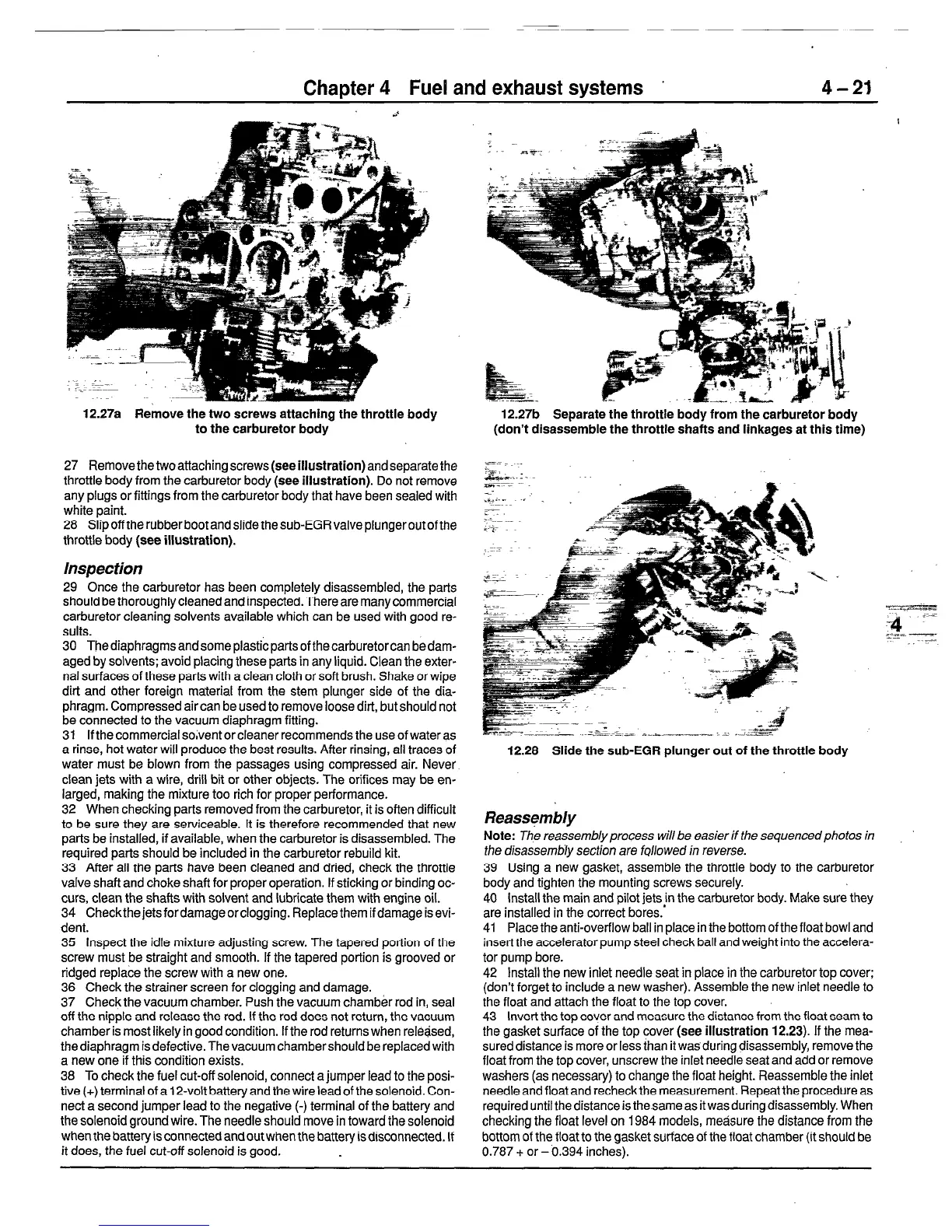

28 Slipoff therubberbootandslidethesub-EGRvalveplungeroutofthe

throttle body (see illustration).

Inspection

29 Once the carburetor has been completely disassembled, the parts

should be thoroughly cleaned and inspected. There are many commercial

carburetor cleaning solvents available which can be used with good re-

sults.

30 Thediaphragmsandsomeplasticpartsofthecarburetorcan bedam-

aged by solvents; avoid placing these parts in any liquid. Clean the exter-

nal surfaces of these parts with a clean cloth or soft brush. Shake or wipe

dirt and other foreign material from the stem plunger side of the dia-

phragm. Compressed air can be used to remove loose dirt, but should not

be connected to the vacuum diaphragm fitting.

31 If the commercial solvent or cleaner recommends the use of water as

a rinse, hot water will produce the best results. After rinsing, all traces of

water must be blown from the passages using compressed air. Never

clean jets with a wire, drill bit or other objects. The orifices may be en-

larged, making the mixture too rich for proper performance.

32 When checking parts removed from the carburetor, it is often difficult

to be sure they are serviceable. It is therefore recommended that new

parts be installed, if available, when the carburetor is disassembled. The

required parts should be included in the carburetor rebuild kit.

33 After all the parts have been cleaned and dried, check the throttle

valve shaft and choke shaft for proper operation. If sticking or binding oc-

curs, clean the shafts with solvent and lubricate them with engine oil.

34 Checkthejetsfordamageorclogging. Replacethemifdamageisevi-

dent.

35 Inspect the idle mixture adjusting screw. The tapered portion of the

screw must be straight and smooth. If the tapered portion is grooved or

ridged replace the screw with a new one.

36 Check the strainer screen for clogging and damage.

37 Check the vacuum chamber. Push the vacuum chamber rod in, seal

off the nipple and release the rod. If the rod does not return, the vacuum

chamber is most likely in good condition. If the rod returns when rel&j.sed,

the diaphragm is defective. The vacuum chamber should be replaced with

a new one if this condition exists.

38 To check the fuel cut-off solenoid, connect a jumper lead to the posi-

tive (+) terminal of a 12-volt battery and the wire lead of the solenoid. Con-

nect a second jumper lead to the negative (-) terminal of the battery and

the solenoid ground wire. The needle should move in toward the solenoid

when the battery is connected and out when the battery is disconnected. If

it does, the fuel cut-off solenoid is good.

12.27b Separate the throttle body from the carburetor body

(don’t disassemble the throttle shafts and linkages at this time)

12.28 Slide the sub-EGR plunger out of the throttle body

Reassembly

Note:

The reassembly process will be easier if the sequencedphotos in

the disassembh section are

fqllowed

in reverse.

39 Using a new gasket, assemble the throttle body to the carburetor

body and tighten the mounting screws securely.

40 install the main and pilot jets in the carburetor body. Make sure they

are installed in the correct bores.’

41 Place the anti-overflow ball in place in the bottom of the float bowl and

insert the accelerator pump steel check ball and weight into the accelera-

tor pump bore.

42 Install the new inlet needle seat in place in the carburetor top cover;

(don’t forget to include a new washer). Assemble the new inlet needle to

the float and attach the float to the top cover.

43 Invert the top cover and measure the distance from the float seam to

the gasket surface of the top cover (see illustration 12.23). If the mea-

sured distance is more or less than it was during disassembly, remove the

float from the top cover, unscrew the inlet needle seat and add or remove

washers (as necessary) to change the float height. Reassemble the inlet

needle and float and recheck the measurement. Repeat the procedure as

required until the distance is the same as it was during disassembly. When

checking the float level on 1984 models, measure the distance from the

bottom of the float to the gasket surface of the float chamber (it should be

0.787 + or - 0.394 inches).

Loading...

Loading...