2D-8 Chapter 2 Part D General engine overhaul procedures

Four cylinder and V-6 engines

Model Engine number

(Displacement)

Valve type

Pick-up

G63B . .

G63B . .

G54B . .

G54B .

4664

6672 . .

Montero

6G72 .

G54B .

.

(2.0L)(1983-1984)

(2.OL) (1985-l 989)

(2.6L) (1983-1984)

(2.6L) (1985-l 989)

(2.4L) (1990 on) .

(3.OL) (1990 on) .

(3.OL) (1989 on) .

(2.6L) . . . . . .

.

. .

. Adjustable w/Jet valve

. . Hydraulic w/Jet valve

. Adjustable w/Jet valve

. Hydraulic w/Jet valve

. Hydraulic we/Jet valve

. Hydraulic we/Jet valve

. Hydraulic we/Jet valve

. . Hydraulic w/Jet valve

1.4 Engine Identification Chart

1

General information

Included in this portion of Chapter 2 are the general overhaul proce-

dures for the cylinder head(s) and internal engine components.

The information ranges from advice concerning preparation for an

overhaul and the purchase of replacement parts to detailed, step-by-step

procedures covering removal and installation of internal engine compo-

nents and the inspection of parts.

The following Sections have been written based on the assumption the

engine has been removed from the vehicle. For information concerning

in-vehicleengine repair, as well as removal and installation of the external

components necessary for the overhaul, see Part A (2.6L engine), Part

B (2OL and 2.4L engines) or Part C (3.OL V6 engine) of this Chapter.

The Specifications included in this Part are only those necessary for

the inspection and overhaul procedures which follow. Refer to Parts A, B

and C for additional Specifications.

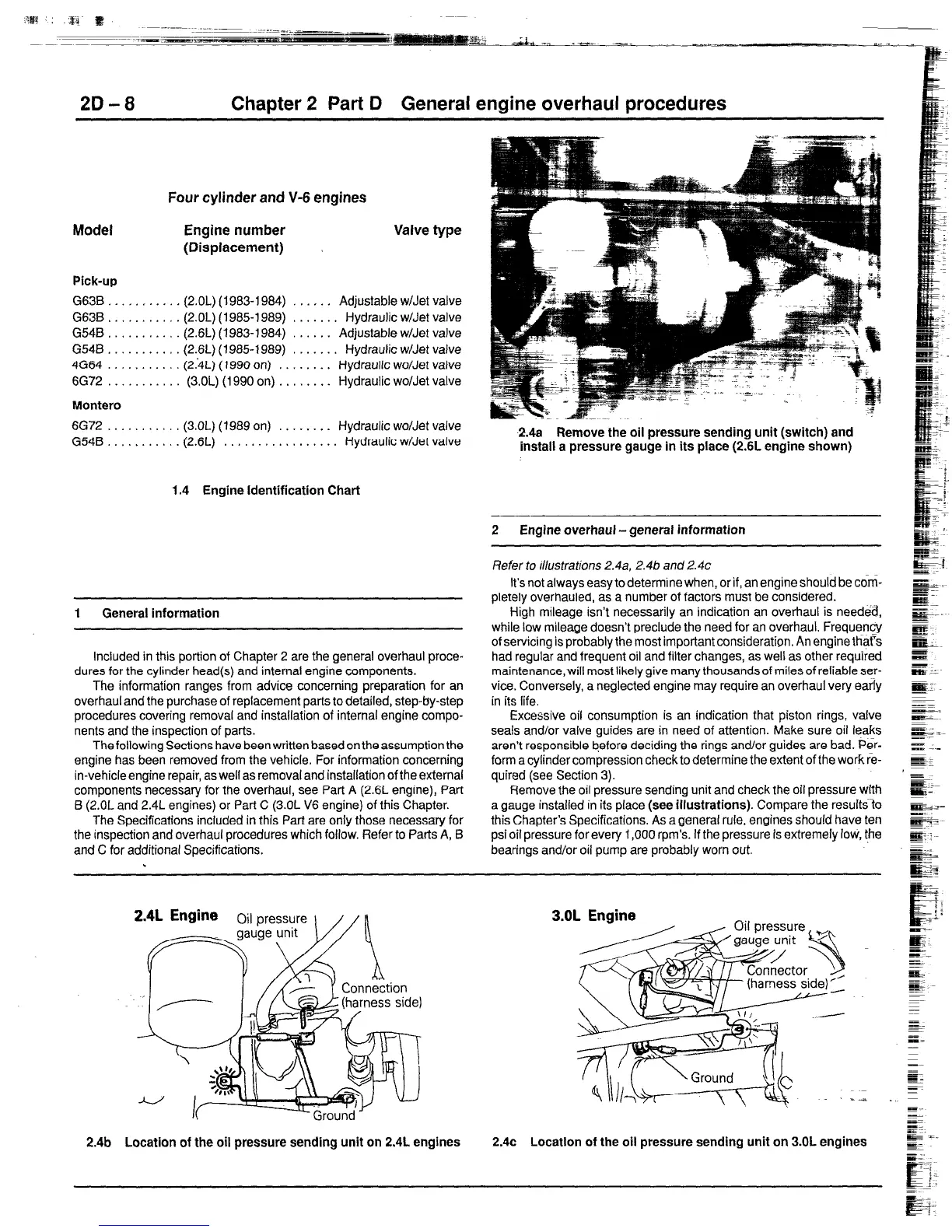

2.4a Remove the oil pressure sending unit (switch) and

install a pressure gauge in its place (2.6L engine shown)

2

Engine overhaul-general information

Refer to ksfrations 2.4~1, 2.46 and 2.4~

It’s not always easy to determine when, or if, an engine should be com-

pletely overhauled, as a number of factors

must

be considered.

High mileage isn’t necessarily an indication an overhaul is needed,

while low mileage doesn’t preclude the need for an overhaul. Frequency

of servicing is probably the most important consideration. An engine that%

had regular and frequent oil and filter changes, as well as other required

maintenance,will most likely give many thousands of miles of reiiable ser-

vice. Conversely, a neglected engine may require an overhaul very early

in its life.

Excessive oil consumption is an indication that piston rings, valve

seals and/or valve guides are in need of attention. Make sure oil leaks

aren’t responsible before deciding the rings and/or guides are

bad.

Per-

form a cyiinder compression check to determine the extent of the work re-

quired (see Section 3).

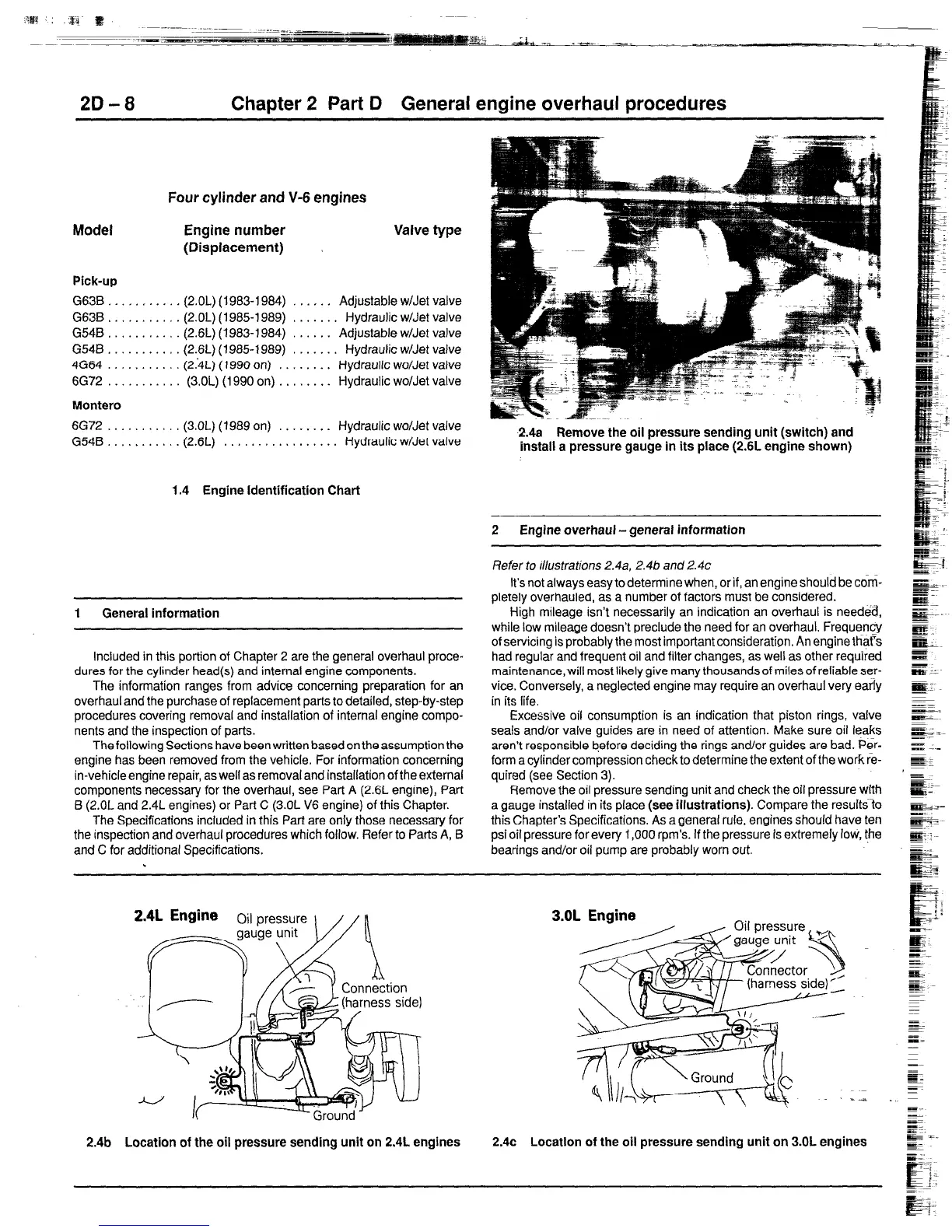

Remove the oil pressure sending unit and check the oil pressure with

a gauge installed in ifs

place (see illustrations).

Compare the results to

this Chapter’s Specifications. As a general rule, engines should have ten

psi oil pressure for every 1,000 rpm’s. If the pressure Is extremely low, the

bearings and/or oil pump are probably worn out.

3.OL Engine

2.4b Location of the oil pressure sending unit on 2.4L engines

2.4c Locatlon of the oil pressure sending unit on 3.OL engines

Loading...

Loading...