20-14 Chapter 2 Part D General engine overhaul procedures

8.2 A small plastic bag, with an appropriate label, can be used

8.3 Use a valve spring compressor to compress the spring, then

to store the valve train components so they can be kept together

remove the keepers from the valve stem

and reinstalled in the original location

2 Before the valves are removed, arrange to label and store them,

along with their related components, so they can be kept separate and re-

installed in their original locations

(see illustration).

3 Compress the springs on the first valve with a spring compressor and

remove the keepers

(see illustration).

Carefully release the valve spring

compressor and remove the retainer, the spring and the spring seat (if

used).

I

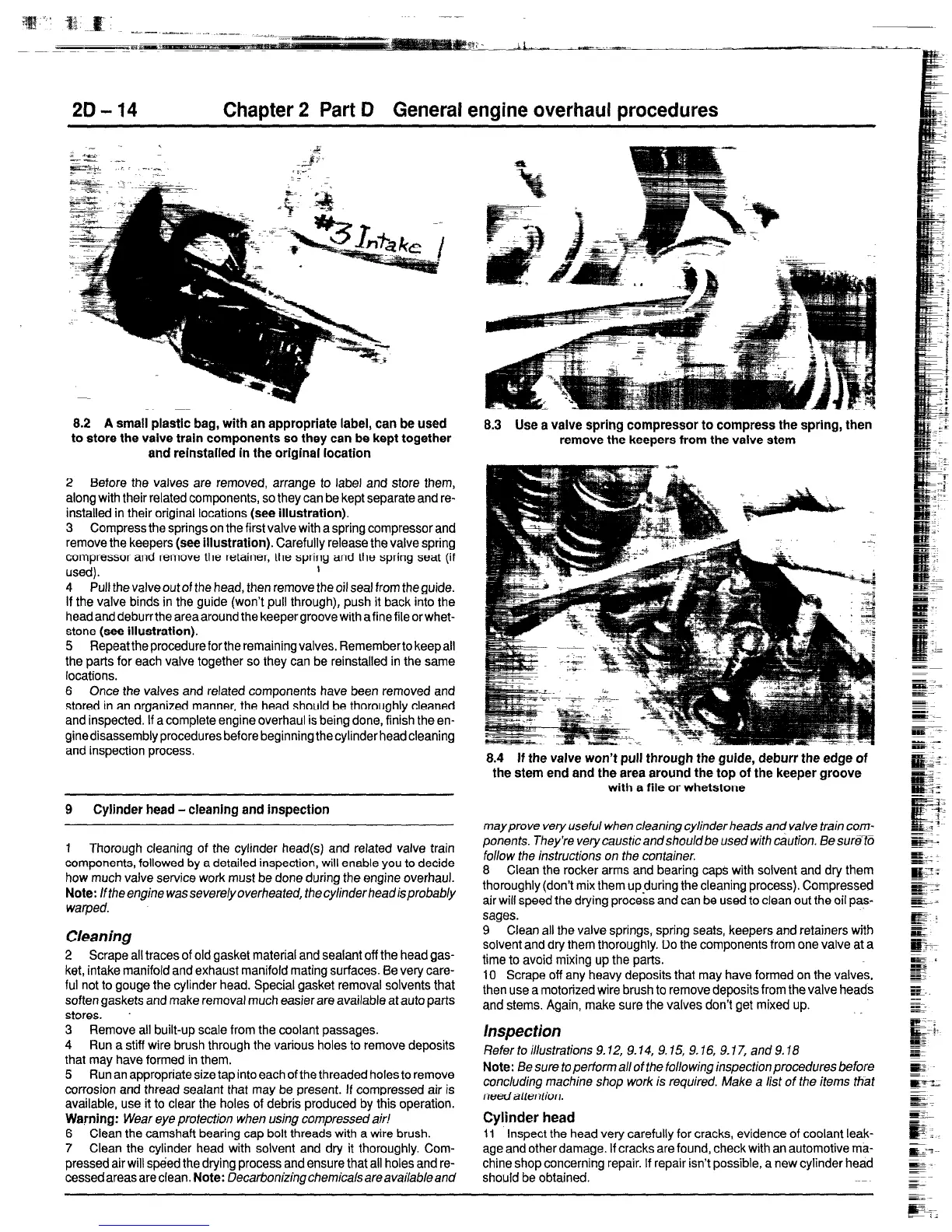

4 Pull the valve out of the head, then remove the oil seal from the guide.

If the valve binds in the guide (won’t pull through), push it back into the

headanddeburrtheareaaround the keepergroovewithafinefileorwhet-

stone

(see illustration).

5 Repeattheprocedurefortheremainingvalves. Remembertokeepall

the parts for each valve together so they can be reinstalled in the same

locations.

6 Once the valves and related components have been removed and

stored in an organized manner, the head should be thoroughly cleaned

and inspected. If a complete engine overhaul is being done, finish the en-

ginedisassembly procedures before beginning the cylinder head cleaning

and inspection process.

8.4 If the valve won’t pull through the guide, deburr the edge

of

the stem end and the area around the top of the keeper groove

with a file or whetstone

9 Cylinder head - cleaning and inspection

1 Thorough cleaning of the cylinder head(s) and related valve train

components, followed by a detailed inspection, will enable you to decide

how much valve service work must be done during the engine overhaul.

Note:

lftheengine wasseveretyoverheafed, fhecylinderheadisprobably

warped.

Cleaning

2 Scrape all traces of old gasket material and sealant off the head gas-

ket, intake manifold and exhaust manifold mating surfaces. Be very care-

ful not to gouge the cylinder head. Special gasket removal solvents that

soften gaskets and make removal much easier are available at auto parts

stores.

3 Remove all built-up scale from the coolant passages.

4 Run a stiff wire brush through the various holes to remove deposits

that may have formed in them.

5 Run an appropriate size tap into each of the threaded holes to remove

corrosion and thread sealant that may be present. If compressed air is

available, use it to clear the holes of debris produced by this operation.

Warning:

Wear eye protection when using compressed air!

6 Clean the camshaft bearing cap bolt threads with a wire brush.

7 Clean the cylinder head with solvent and dry it thoroughly. Com-

pressed air will speed the drying process and ensure that all holes and re-

cessedareasareclean.

Note:

Oecarbonizingchemicalsareavaitableand

mayprove very useful when cleaning cylinder heads and valve train com-

ponents. They’re verycausticandshouldbeused with caution. Besure’to

follow the instructions on the container.

8 Clean the rocker arms and bearing caps with solvent and dry them

thoroughly (don’t mix them upduring the cleaning process). Compressed

air will speed the drying process and can be used to clean out the oil pas-

sages.

9 Clean all the valve springs, spring seats, keepers and retainers with

solvent and dry them thoroughly. Do the components from one valve at s

time to avoid mixing up the parts.

10 Scrape off any heavy deposits that may have formed on the valves,

then use a motorized wire brush to remove deposits from the valve heads

and stems. Again, make sure the valves don’t get mixed up.

Inspection

Refer to illustrations 9.12, 9.14, 9.15, 9.16, 9.17, and 9.18

Note:

Be sure to perform at/ of the following inspection procedures before

concluding machine shop work is required. Make a list of fhe items that

need attention.

Cylinder head

11 Inspect the head very carefully for cracks, evidence of coolant leak-

age and other damage. If cracks are found, check with an automotive ma-

chine shop concerning repair. If repair isn’t possible, a new cylinder head

should be obtained.

Loading...

Loading...