1-24 Chapter 1 Tune-up and routine maintenance

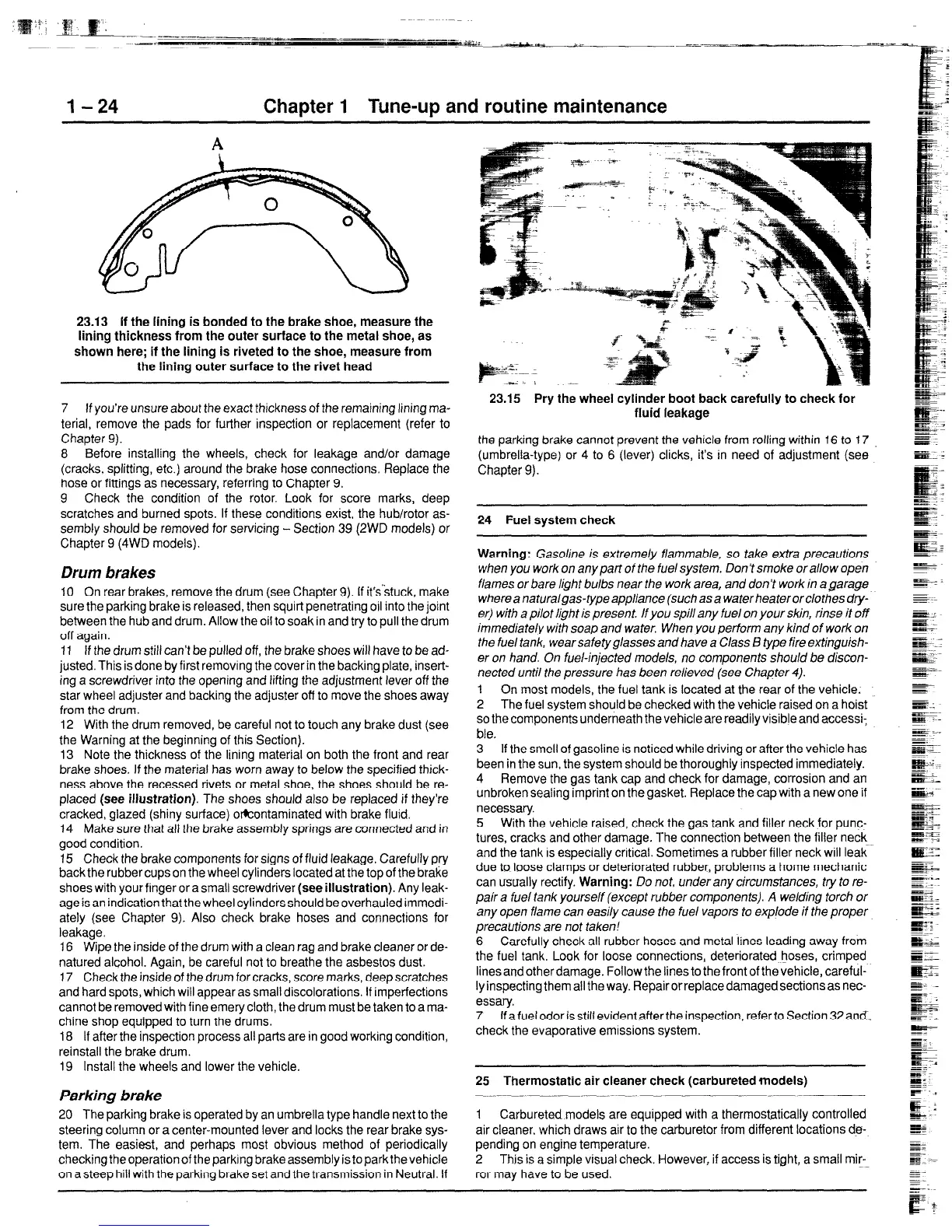

23.13 If the lining is bonded to the brake shoe, measure the

lining thickness from the outer surface to the metal shoe, as

shown here; if the lining is riveted to the shoe, measure from

the lining outer surface to the rivet head

7 If you’re unsure about the exact thickness of the remaining lining ma-

terial, remove the pads for further inspection or replacement (refer to

Chapter 9).

8 Before installing the wheels, check for leakage and/or damage

(cracks, splitting, etc.] around the brake hose connections. Replace the

hose or fittings as necessary, referring to Chapter 9.

9 Check the condition of the rotor. Look for score marks, deep

scratches and burned spots. If these conditions exist, the hub/rotor as-

sembly should be removed for servicing - Section 39 (2WD models) or

Chapter 9 (4WD models).

Drum brakes

10 On rear brakes, remove the drum (see Chapter 9). If it’sstuck, make

sure the parking brake is released, then squirt penetrating oil into the joint

between the hub and drum. Allow the oil to soak in and try to pull the drum

off again.

11 If the drum still can’t be pulled off, the brake shoes will have to be ad-

justed. This is done by first removing the cover in the backing plate, insert-

ing a screwdriver into the opening and lifting the adjustment lever off the

star wheel adjuster and backing the adjuster off to move the shoes away

from the drum.

12 With the drum removed, be careful not to touch any brake dust (see

the Warning at the beginning of this Section).

13 Note the thickness of the lining material on both the front and rear

brake shoes. If the material has worn away to below the specified thick-

ness above the recessed rivets or metal shoe, the shoes should be re-

placed (see illustration). The shoes should also be replaced if they’re

cracked, glazed (shiny surface) okontaminated with brake fluid.

14 Make sure that all the brake assembly springs are connected and in

good condition.

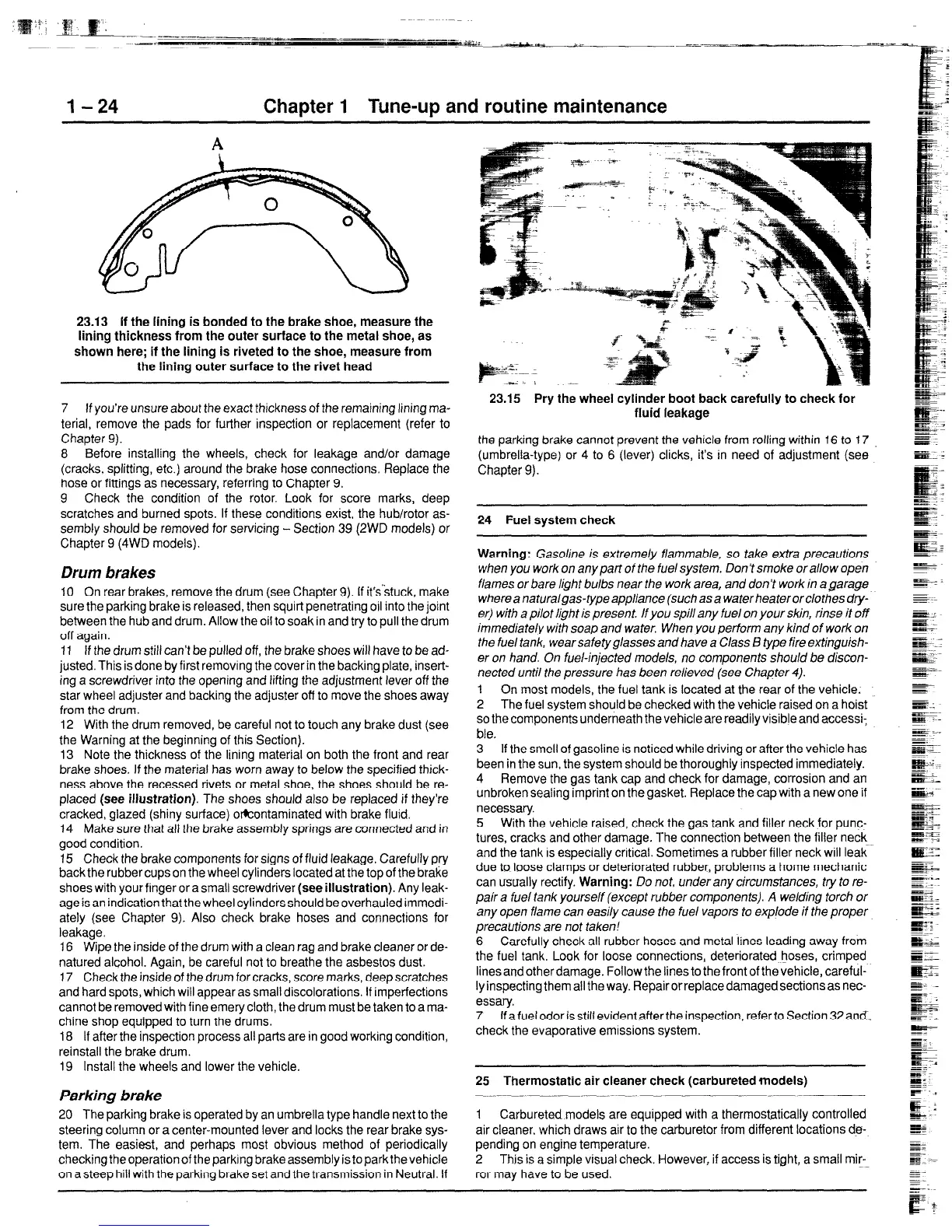

15 Check the brake components for signs of fluid leakage. Carefully pry

back the rubber cups on the wheel cylinders located at the top of the brake

shoes with your finger or a small screwdriver (see illustration). Any leak-

age is an indication that the wheel cylinders should be overhauled immedi-

ately (see Chapter 9). Also check brake hoses and connections for

leakage.

16 Wipe the inside of the drum with a clean rag and brake cleaner or de-

natured alcohol. Again, be careful not to breathe the asbestos dust.

17 Check the inside of the drum for cracks, score marks, deep scratches

and hard spots, which will appear as small discolorations. If imperfections

cannot be removed with fine emery cloth, the drum must be taken to a ma-

chine shop equipped to turn the drums.

18 If after the inspection process all parts are in good working condition,

reinstall the brake drum.

19 Install the wheels and lower the vehicle.

Parking brake

20 The parking brake is operated by an umbrella type handle next to the

steering column or a center-mounted lever and locks the rear brake sys-

tem. The easiest, and perhaps most obvious method of periodically

checkingtheoperationof the parking brake assemblyistoparkthevehicle

on a steep hill with the parking brake set and the transmission in Neutral. If

23.15 Pry the wheel cylinder boot back carefully to check for

fluid leakage

the parking brake cannot prevent the vehicle from rolling within 16 to 17

(umbrella-type) or 4 to 6 (lever) clicks, it’s in need of adjustment (see

Chapter 9).

24 Fuel system check

Warning: Gasoline is extremely flammable, so take extra precautions

when you work on any part of the fuel system. Don’t smoke or a/low open

flames or bare light bulbs near the work area, and don? work in a garage

whereanaturalgas-typeapp/iance(suchasa waterheaterorclothesdry-

e@ with a pilot light is present. /f you spill any fuel on your skin, rinse it off

immediate/y with soap and water. When you perform any kind of work on

the fuel tank, wearsafetyglasses and have a C/ass B type fire extinguish-

er on hand. On fuel-injected mode/s, no components should be discon-

nected until the pressure has been relieved (see Chapter 4).

1 On most models, the fuel tank is located at the rear of the vehicle.

2 The fuel system should be checked with the vehicle raised on a hoist

so the components underneath thevehicle are readily visible and accessi-

ble.

3 If the smell of gasoline is noticed while driving or after the vehicle has

been in the sun, the system should be thoroughly inspected immediately.

4 Remove the gas tank cap and check for damage, corrosion and an

unbroken sealing imprint on the gasket. Replace the capwith a new one if

necessary.

5 With the vehicle raised, check the gas tank and filler neck for punc-

tures, cracks and other damage. The connection between the filler neck

and the tank is especially critical. Sometimes a rubber filler neck will leak

due to loose clamps or deteriorated rubber, problems a home mechanic

can usually rectify. Warning: Do not, underanycircumstances, try to re-

pair a fuel tank yourself (except rubber components). A welding torch or

any open flame can easily cause the fuel vapors to explode if the proper

precautions are not taken!

6 Carefully check all rubber hoses and metal lines leading away from

the fuel tank. Look for loose connections, deteriorated hoses, crimped

linesandotherdamage. Followthelinestothefrontofthevehicle,careful-

ly inspecting them all the way. Repair or replace damaged sections as nec-

essary.

7 If a fuel odor is still evident after the inspection, refer to Section 32 and-

check the evaporative emissions system.

25 Thermostatic air cleaner check (carburetedmodels)

1 Carbureted models are equipped with a thermostatically controlled

air cleaner, which draws air to the carburetor from different locations de-

pending on engine temperature.

2 This is a simple visual check. However, if access is tight, a small mir-

ror may have to be used.

Loading...

Loading...