Chapter 1 Tune-up and routine maintenance

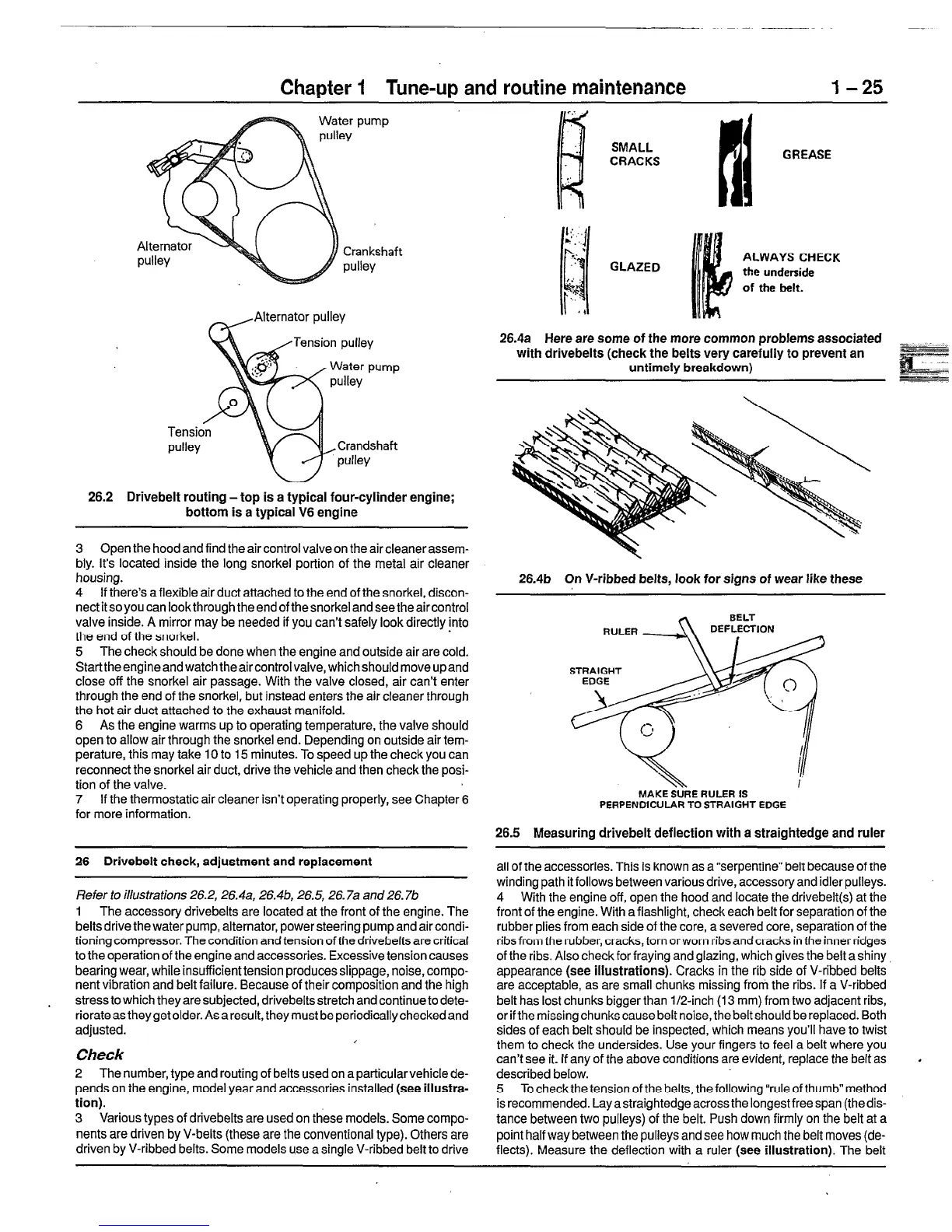

26.2

-Alternator pulley

Crandshaft

pulley

Drivebelt routing -top is a typical four-cylinder

bottom is a typical V6 engine

engine;

3 Open the hood and find the air control valve on the air cleaner assem-

bly. It’s located inside the long snorkel portion of the metal air cleaner

housing.

4 If there’s a flexible air duct attached to the end of the snorkel, discon-

nectitsoyoucanlookthroughtheendofthesnorkelandseetheaircontrol

valve inside. A mirror may be needed if you can’t safely look directly into

the end of the snorkel.

5 The check should be done when the engine and outside air are cold.

Starttheengineandwatchtheaircontrolvalve, whichshould moveupand

close off the snorkel air passage. With the valve closed, air can’t enter

through the end of the snorkel, but instead enters the air cleaner through

the hot air duct attached to the exhaust manifold.

6 As the engine warms up to operating temperature, the valve should

open to allow air through the snorkel end. Depending on outside air tem-

perature, this may take 10 to 15 minutes. To speed up the check you can

reconnect the snorkel air duct, drive the vehicle and then check the posi-

tion of the valve.

7 If the thermostatic air cleaner isn’t operating properly, see Chapter 6

for more information.

26 Drivebelt check, adjustment and replacement

,

Refer to illustrations 26.2,26.4a, 26.4b, 26.5,26.7a and 26.7b

1 The accessory drivebelts are located at the front of the engine. The

belts drive the water pump, alternator, power steering pump and air condi-

tioning compressor. The condition and tension of the drivebelts are critical

to the operation of the engine and accessories. Excessive tension causes

bearing wear, while insufficient tension produces slippage, noise, compo-

nent vibration and belt failure. Because of their composition and the high

stress to which they are subjected, drivebelts stretch and continue to dete-

riorateastheyget older. Asaresult, they must beperiodicailycheckedand

adjusted.

,

Check

2 The number, type and routing of belts used on aparticuiarvehicle de-

pends on the engine, model year and accessories installed

(see iiiustra-

tion).

3 Various types of drivebelts are used on these models. Some compo-

nents are driven by V-belts (these are the conventional type). Others are

driven by V-ribbed belts. Some models use a single V-ribbed belt to drive

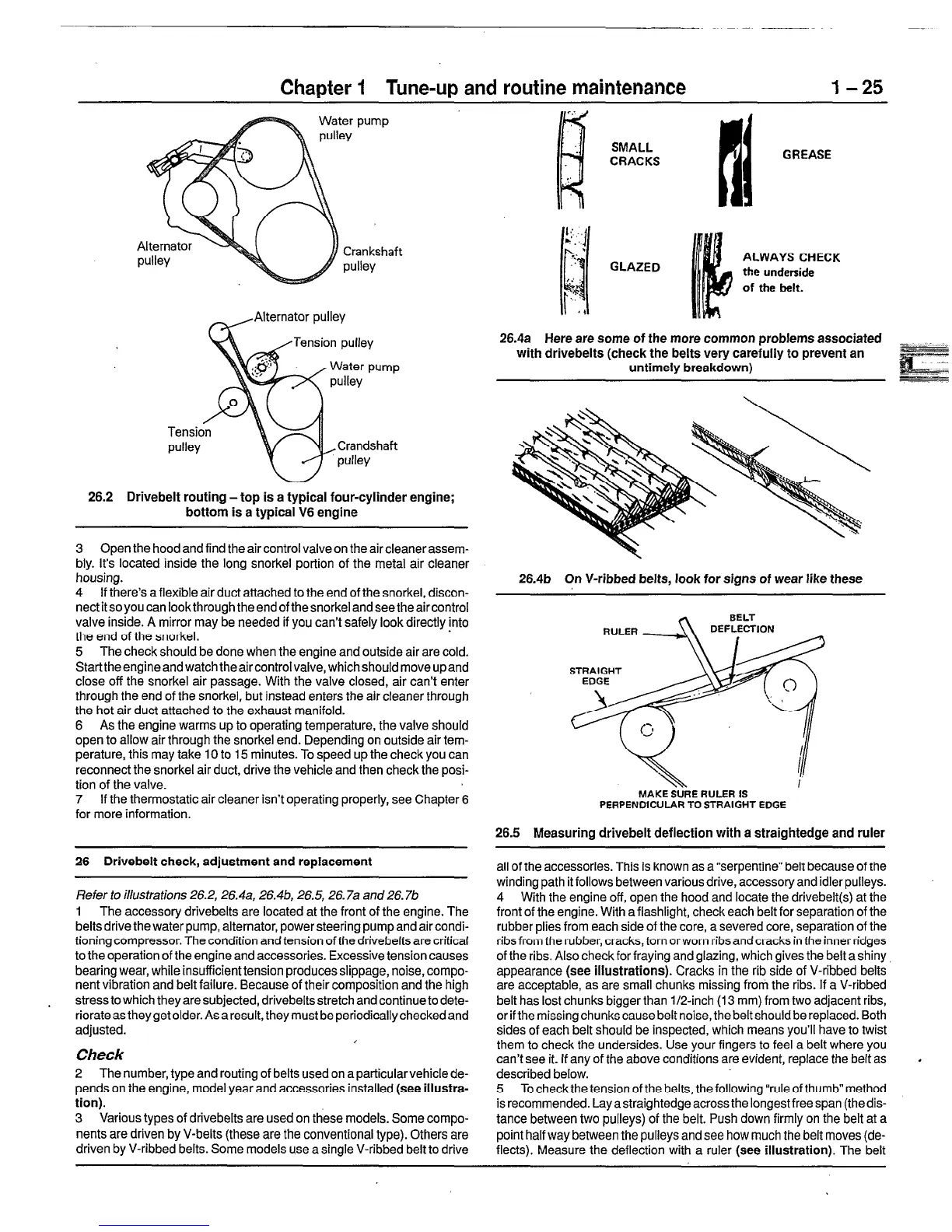

GREASE

GLAZED

ALWAYS CHECK

the

underside

of the belt.

26.4a Here are some of the more common problems associated _

with drivebelts (check the belts very carefully to prevent an -*

untimely breakdown)

26.4b On V-ribbed belts, look for signs of wear like these

DEFLECTION

, . .

MAKE SURE RULER IS

PERPENDICULAR TO STRAIGHT EDGE

26.5 Measuring drivebelt deflection with a straightedge and ruler

all of the accessories. This is known as a “serpentine” belt because of the

winding path it follows between various drive, accessory and idler pulleys.

4 With the engine off, open the hood and locate the drivebelt at the

front of the engine. With a flashlight, check each belt for separation of the

rubber plies from each side of the core, a severed core, separation of the

ribs from the rubber, cracks, torn or worn ribs and cracks in the inner ridges

of the ribs. Also check for fraying and glazing, which gives the belt a shiny

appearance

(see illustrations).

Cracks in the rib side of V-ribbed belts

are acceptable, as are small chunks missing from the ribs. If a V-ribbed

belt has lost chunks biggerthan l/2-inch (13 mm} from two adjacent ribs,

orifthemissingchunkscausebeltnoise, thebeltshould bereplaced. Both

sides of each belt should be inspected, which means you’ll have to twist

them to check the undersides. Use your fingers to feel a belt where you

can’t see it. If any of the above conditions are evident, replace the belt as

described below.

5 To check the tension of the belts, the following “rule of thumb” method

is recommended. Lay astraightedge across the longest free span (the dis-

tance between two pulleys) of the belt. Push down firmly on the belt at a

point half way between the pulleys and see how much the belt moves (de-

flects). Measure the deflection with a ruler (see

illustration).

The belt

Loading...

Loading...