1-26 Chapter 1 Tune-up and routine maintenance

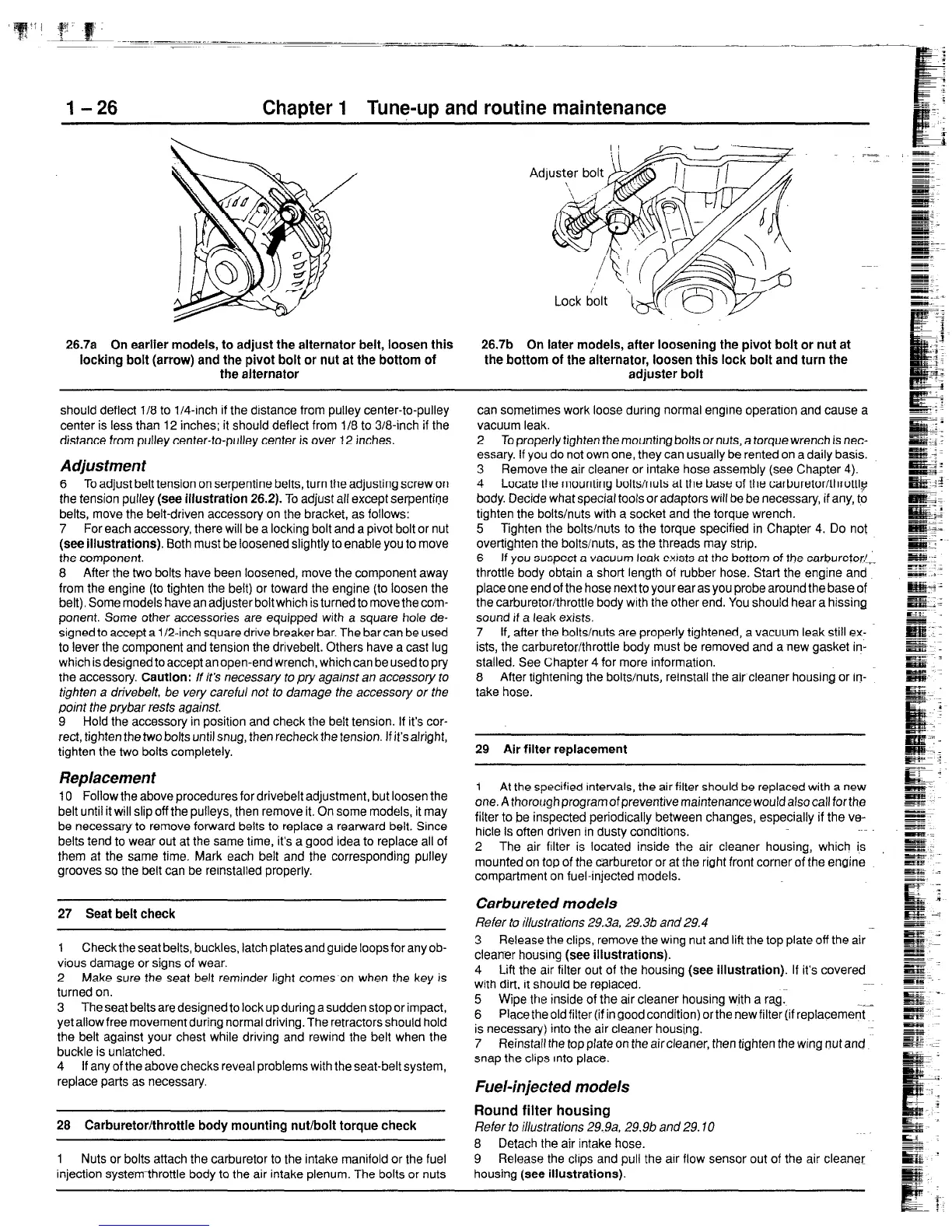

26.7a On earlier models, to adjust the alternator belt, loosen this

locking bolt (arrow) and the pivot bolt or nut at the bottom of

the alternator

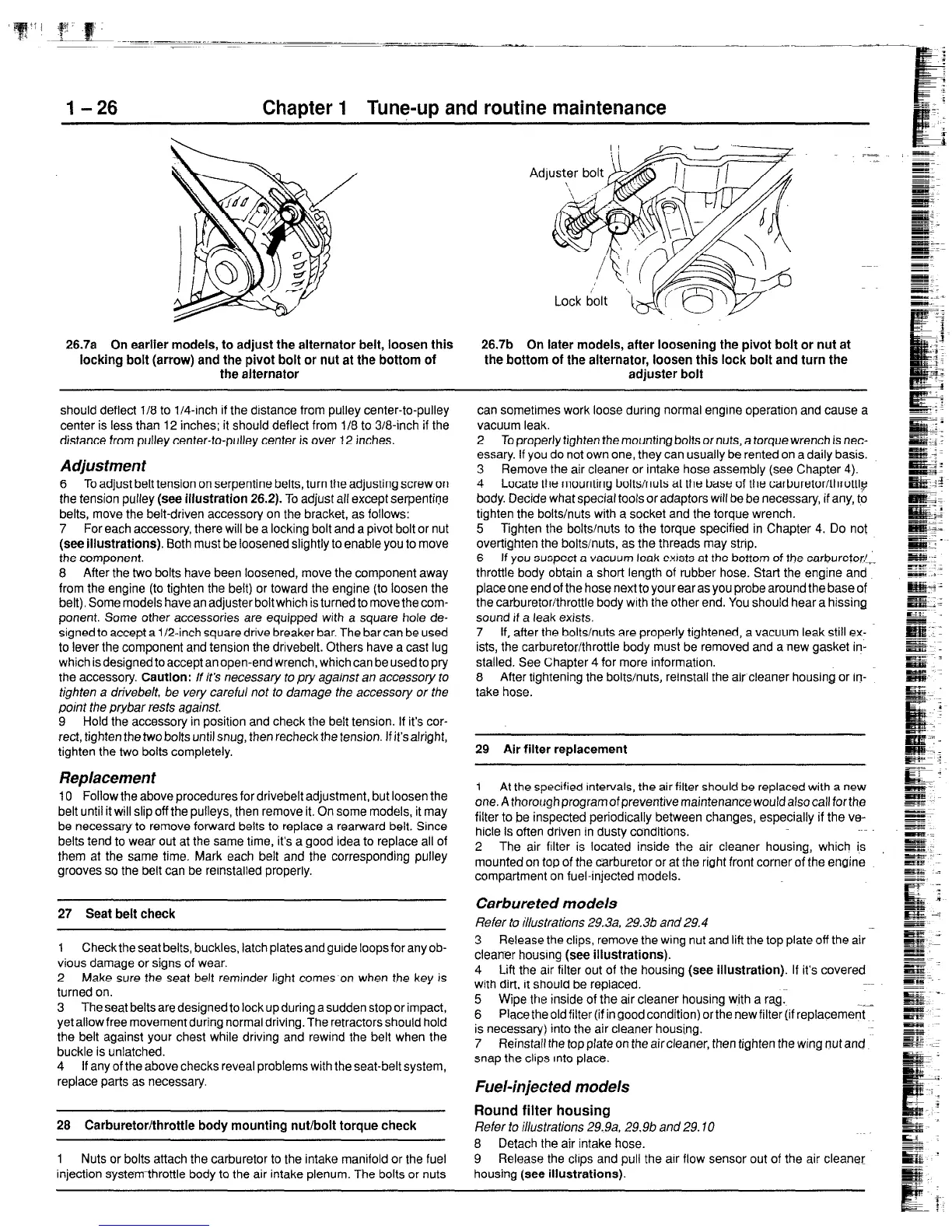

26.7b On later models, after loosening the pivot bolt or nut at

the bottom of the alternator, loosen this lock bolt and turn the

adjuster bolt

should deflect l/8 to l/4-inch if the distance from pulley center-to-pulley

center is less than 12 inches; it should deflect from i/8 to 3/8-inch if the

distance from pulley center-to-pulley center is over 12 inches.

Adjustment

6

To

adjust belt

tension on serpentine belts, turn the adjusting screw on

the tension pulley

(see illustration 26.2).

To

adjust all

except serpentine

belts, move the belt-driven accessory on the bracket, as follows:

7 For each accessory, there will be a locking bolt and a pivot bolt or nut

(see illustrations).

Both must be loosened slightly to enable you to move

the component.

8 After the two bolts have been loosened, move the component away

from the engine (to tighten the belt) or toward the engine (to loosen the

belt). Some models have an adjuster bolt which is turned to move the com-

ponent. Some other accessories are equipped with a square hole de-

signed to accept a 1 /Zinch square drive breaker bar. The bar can be used

to lever the component and tension the drivebelt. Others have a cast lug

which is designed to accept an open-end wrench, which can be used to pry

the

accessory. Caution:

If it’s necessary to pry against an accessory to

tighten a drivebelt, be very careful not to damage the accessory or the

point the prybar rests against.

9 Hold the accessory in position and check the belt tension. If its cor-

rect, tighten the two bolts until snug, then recheck the tension. If it’salright,

tighten the two bolts completely.

Replacement

IO Follow the above procedures for drivebelt adjustment, but loosen the

belt until it will slip off the pulleys, then remove it. On some models, it may

be necessary to remove forward belts to replace a rearward belt. Since

belts tend to wear out at the same time, its a good idea to replace all of

them at the same time. Mark each belt and the corresponding pulley

grooves so the belt can be reinstalled properly.

27 Seat belt check

1 Check the seat belts, buckles, latch plates and guide loops for any ob-

vious damage or signs of wear.

2 Make sure the seat belt reminder light comes on when the key is

turned on.

3

The

seat belts

are designed to lock up during a sudden stop or impact,

yet allow free movement during normal driving. The retractors should hold

the belt against your chest while driving and rewind the belt when the

buckle is unlatched.

4 If any of the above checks reveal problems with the seat-belt system,

replace parts as necessary.

28 Carburetor/throttle body mounting nut/bolt torque check

1

Nuts or bolts attach the carburetor to the intake manifold or the fuel

injection systemthrottle body to the air intake plenum. The bolts or nuts

can sometimes work loose during normal engine operation and cause a

vacuum leak.

2 To properly tighten the mounting bolts or nuts, a torque wrench is nec-

essary. If you do not own one, they can usually be rented on a daily basis.

3 Remove the air cleaner or intake hose assembly (see Chapter 4).

4 Locate the mounting bolts/nuts at the base of the carburetor/throttle

body. Decide what special tools or adaptors will be be necessary, if any, to

tighten the bolts/nuts with a socket and the torque wrench.

5 Tighten the bolts/nuts to the torque specified in Chapter 4. Do not

overtighten the bolts/nuts, as the threads may strip.

6 If you suspect a vacuum leak exists at the bottom of the carburetor/+:

throttle body obtain a short length of rubber hose. Start the engine and

place one end of the hose next to your ear as you probe around the base of

the carburetor/throttle body with the other end. You should hear a hissing

sound if a leak exists.

7 If, after the bolts/nuts are properly tightened,

a vacuum

leak still ex-

ists, the carburetor/throttle body must be removed and a new gasket in-

stalled. See Chapter 4 for more information.

8 After tightening the bolts/nuts, reinstall the aiicleaner housing or in-

take hose.

29 Air filter replacement

1 At the specified intervals, the air filter should be replaced with a new

one. A thorough program of preventive maintenance would also call for the

filter to

be

inspected periodically between changes, especially if the ve-

hicle is often driven in dusty conditions.

2 The air filter is located inside the air cleaner housing, which is

mounted on top of the carburetor or at the right front corner of the engine

compartment on fuel-injected models.

Carbureted models

Refer to illustrations 29.3a. 29.3b and 29.4

3 Release the clips, remove the wing nut and lift the top plate off the air

cleaner housing

(see illustrations).

4 Lift the air filter out of the housing

(see illustration).

If it’s covered

with dirt, it should be replaced.

5 Wipe the inside of the air cleaner housing with a rag.

6 Place the old filter (if in good condition) or the new filter (if replacement

is necessary) into the air cleaner housing.

7 Reinstall the top plate on the air cleaner, then tighten the wing nut and

snap the clips Into place.

Fuel-injected models

Round filter housing

Refer fo illusfrafions 29.9a, 29.9b and 29.10

8 Detach the air intake hose.

9 Release the ckps and pull the arr flow sensor out of the air cleaner

housing

(see illustrations).

Loading...

Loading...