-

98

-

'16 • SCM-T-199

9. CONNECTING PIPING WORK

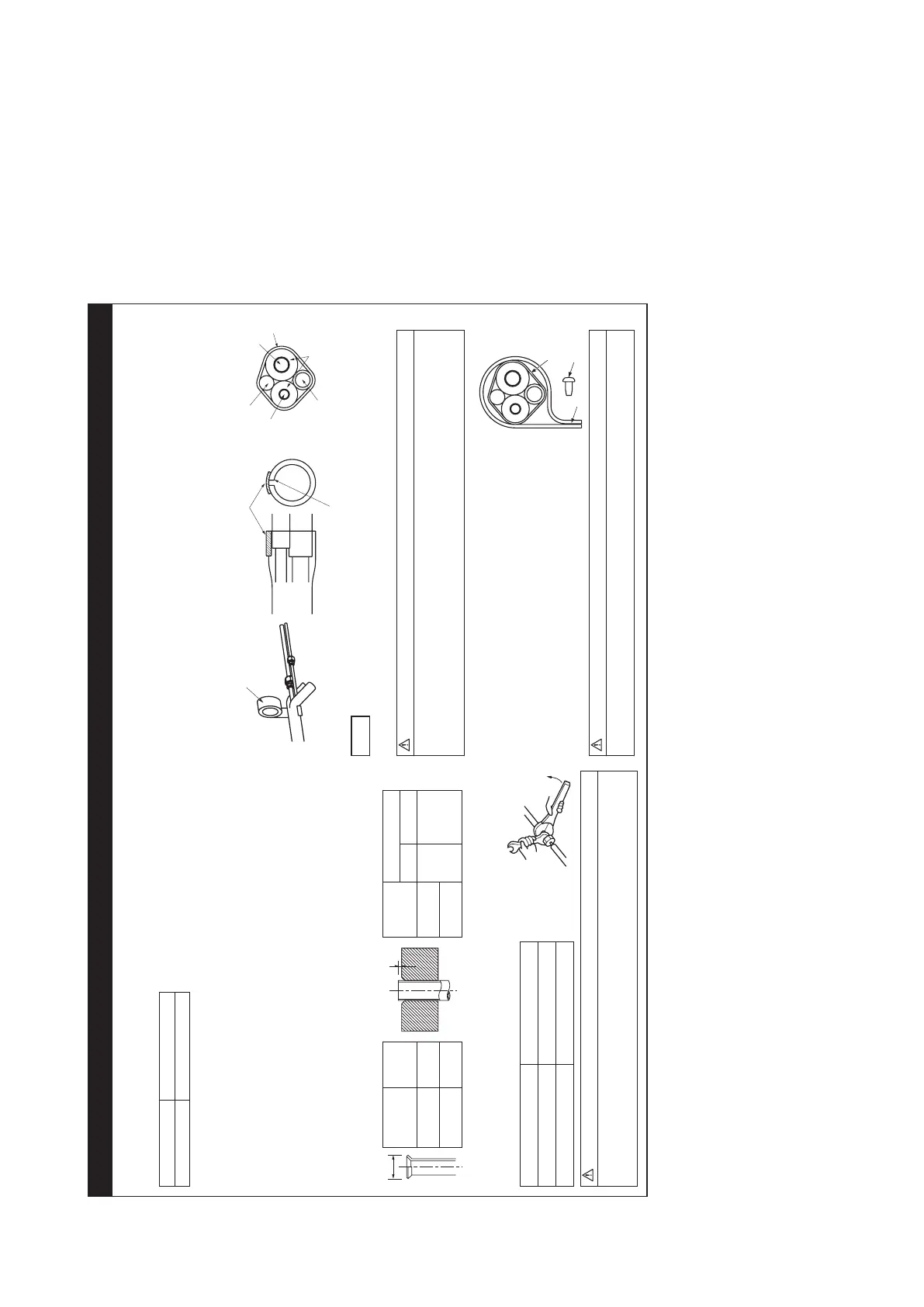

1. Preparation of connecting pipe

1.1. Selecting connecting pipe

Select connecting pipe according to the following table.

Gas pipe ø9.52

Liquid pipe ø6.35

• Pipe wall thickness must be greater than or equal to 0.8 mm.

• Pipe material must be O-type (Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS

77.150.30).

1.2.Cuttingconnectingpipe

(1) Cut the connecting pipe to the required length with pipe cutter.

(2)

Hold the pipe downward and remove the burrs. Make sure that no foreign material enters the pipe.

(3) Cover the connecting pipe ends with the tape.

2.Pipingwork

2.1.Flaringpipe

(1)

Takeoutarenutsfromtheservicevalvesofindoorunitandengagethemontoconnectingpipes.

(2) Flarethepipesaccordingtotableandgureshownbelow.

Flare dimensions for R410A are different from those for conventional refrigerant.

AlthoughitisrecommendedtousethearingtoolsdesignedspecicallyforR410A,conventionalar-

ingtoolscanalsobeusedbyadjustingthemeasurementofprotrusionBwithaareadjustmentgauge.

Copperpipe

outer diameter

A

0

–0.4

Copperpipe

outer diameter

Rigid (clutch) type

R410A Conventional

ø6.35 9.1 ø6.35

0-0.5 1.0-1.5

ø9.52 13.2 ø9.52

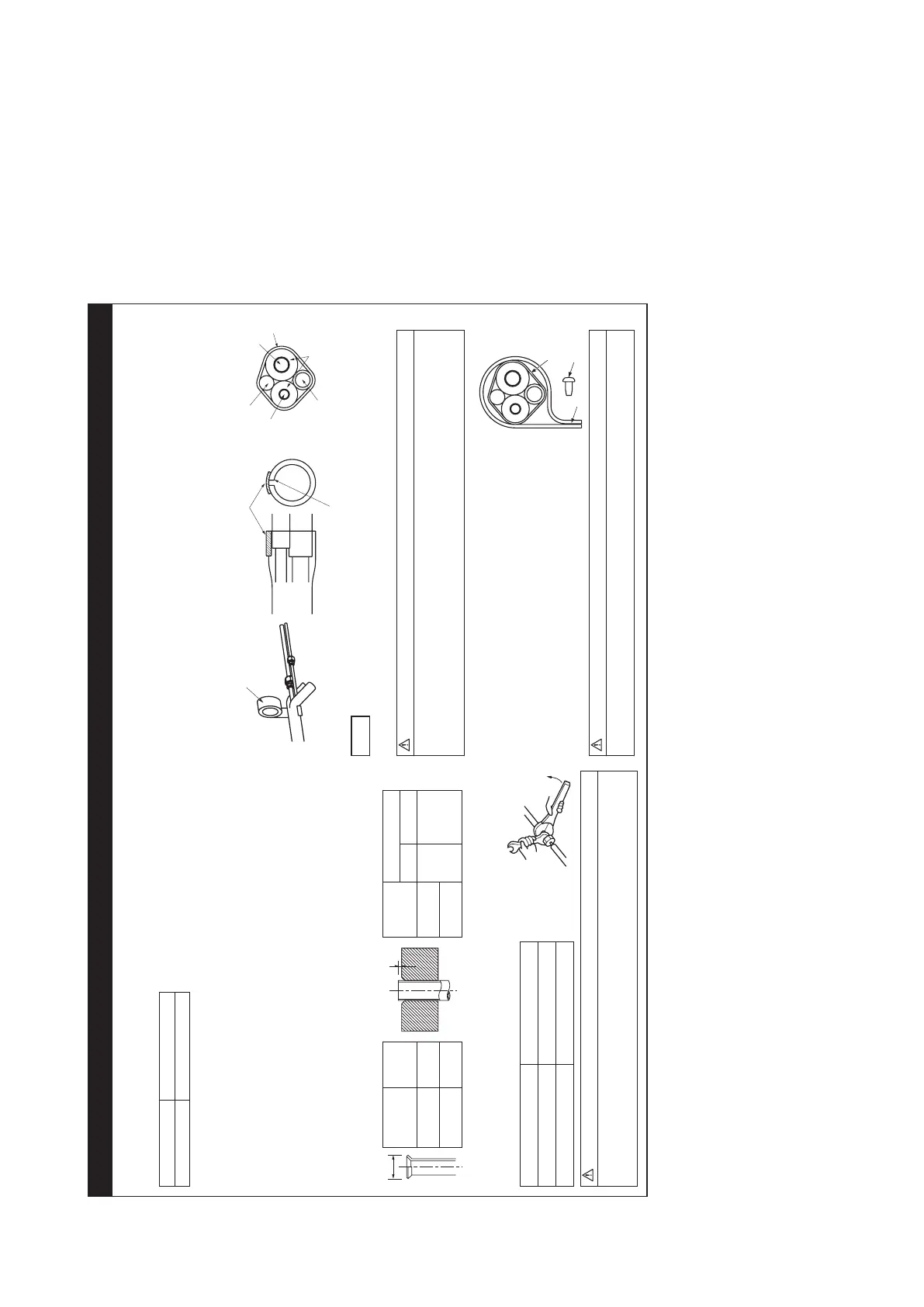

2.2Connectingpipes

(1) Connect pipes on both liquid and gas sides.

(2)Tightennutstospeciedtorqueshowninthetablebelow.

Gas side

Service valve size (mm) Tightening torque (N·m)

ø6.35 (1/4") 14-18

ø9.52 (3/8") 34-42

CAUTION

•

Donotapplyrefrigeratingmachineoiltothearedsurface.Itcancauserefrigerantleakage.

• Donotapplyexcesstorquetothearednuts.Thearednutsmaycrackresultinginrefrigerant

leakage.

3. Heating and condensation prevention

(1) Dress the connecting pipes (both liquid and gas pipes) with insulation to prevent it from heating and

dew condensation.

Use the heat insulating material which can withstand 120°C or higher temperature. Make sure that insu-

lation is wrapped tightly around the pipes and no gap is left between them.

(2) Wrap the refrigerant pipings of indoor unit with indoor unit heat insulation using tape.

(3) Covertheare-connectedjoints(indoorside)withtheindoorunitheatinsulationandwrapitwithanin-

sulation pad (standard accessory provided with indoor unit).

(4) Wrap the connecting pipes, connecting cable and drain hose with the tape.

(2) (3) (4)

Insulation pad

Position it so that the slit area faces upward.

Connecting cable

Liquid pipe

Drain hose

Gas pipe

Insulation

Tape

NOTE

Locations where relative humidity exceeds 70%, both liquid and gas pipes need to be dressed with 20mm

or

thicker heat insulation materials.

CAUTION

• Improper insulation can cause condensate(water) formation during cooling operation.

Condensate can leak or drip causing damage to household property.

• Poor heat insulating capacity can cause pipe outer surface to reach high temperature during heating

operation. It can cause cable deterioration and personal injury.

4. Finishing work

Pipe

assembly

Screw

(1) Make sure that the exterior portion of connecting pipes, connecting cable

and drain hose is wrapped properly with tape. Shape the connecting pipes

to match with the contours of the pipe assembly route.

(2) Fix the pipe assembly with the wall using clamps and screws. Pipe assem-

bly should be anchored every 1.5m or less to isolate the vibration.

(3) Install the service cover securely. Water may enter the unit if service cover

is not installed properly, resulting in unit malfunction and failure.

CAUTION

Make sure that the connecting pipes do not touch the components within the unit. If pipes touch the

internal components, it may generate abnormal sounds and/or vibrations.

Loading...

Loading...