How to determine defective or not defective

(a) Measure continuity by removing the connector at

the edge of temperature detection.

(b) Resistance value at the edge of temperature

detection in normal condition.

(Unit kΩ)

°C Rmin. Rnom. Rmax.

-30 25.293 26.316 27.376

-20 15.125 15.572 16.031

-10 9.342 9.524 9.709

0 5.940 6.000 6.060

10 3.810 3.882 3.995

20 2.505 2.573 2.644

25 2.049 2.113 2.179

30 1.687 1.746 1.808

40 1.163 1.213 1.265

50 0.819 0.860 0.903

(c) If the resistance value is widely out of order,

remove it at the edge of the temperature detection

(with lead) and replace it.

(d) If the above resistance value is normal, check the

controller.

10.17 Td sensor (Td)

It detects delivery temperature of the compressor and

stops the refrigeration unit or opens the liquid injection

electromagnetic valve.

• If the delivery temperature becomes more than 125°C,

opens the liquid injection electromagnetic valve in

order to lower delivery temperature.

• If the delivery temperature becomes more than 135°C,

stops the refrigeration unit.

How to determine defective or not defective:

Measure the resistance value by removing the

connector.

Resistance value in normal condition

200°C 0.430kΩ 100°C 5.228kΩ

175°C 0.738kΩ 25°C 80.470kΩ

115°C 3.352kΩ

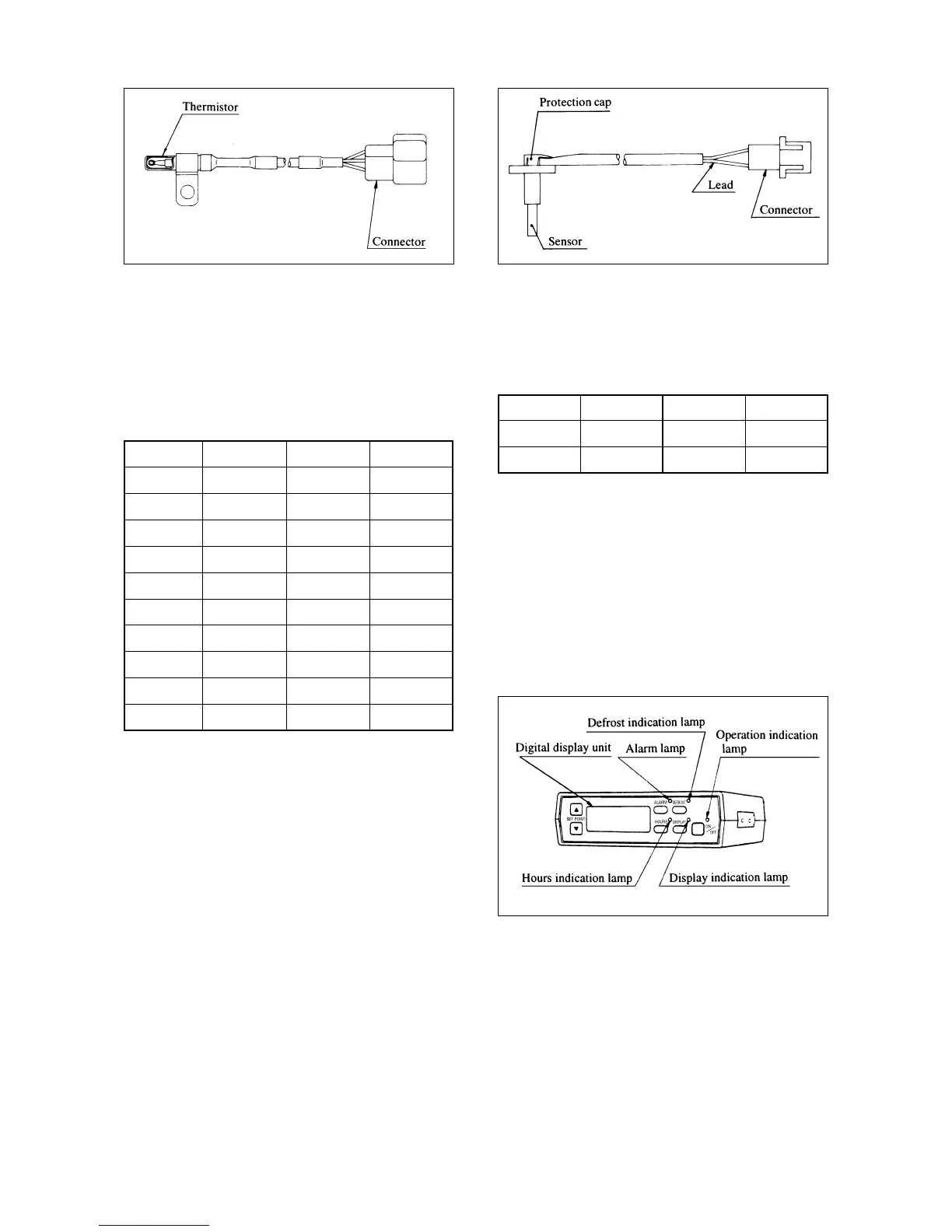

10.18 Controller

A new controller with a character display function has

been adopted, which enables to set digitally a desired

storage temperature accurately. In addition to it, pre-

operation inspection for the refrigeration unit can be

made by a simple button operation and a diagnosis at

the time of the unit being defective can also be made

easily.

Display function

• Operation indication lamp

• Defrost indication lamp

• Alarm lamp

• Hours indication lamp

• Display indication lamp

– 19 –

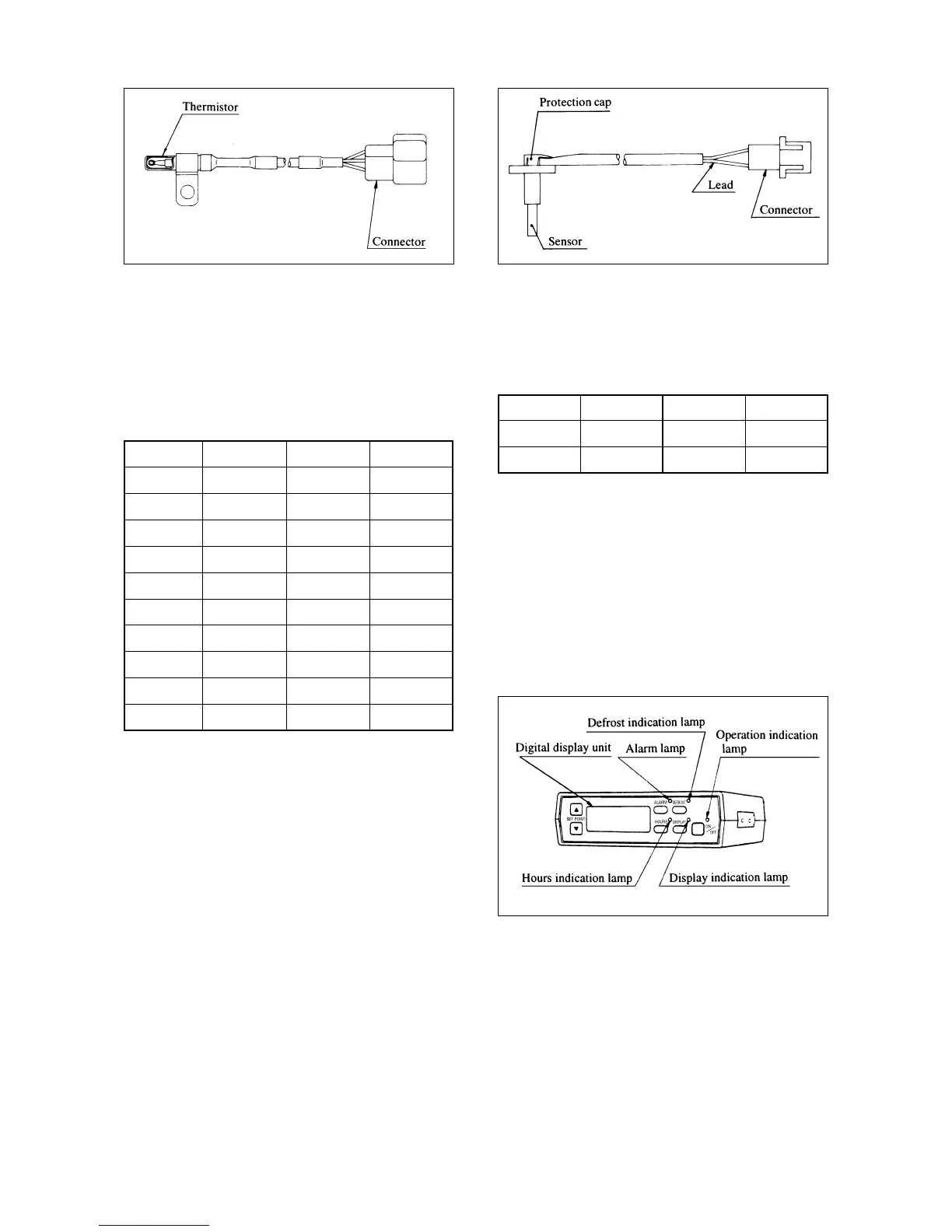

Storage temperature sensor Td sensor

Controller

Loading...

Loading...