Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8533, Japan

Date of publication: December 1, 2021

Printed in Japan

4

Briey press the [PRESET] key until [3] is displayed.

5

Press and hold the [PRESET] key.

》 The number in the next digit blinks.

6

Repeat steps

4

and

5

, so that [3], [0], [0], [0], [0], and [0] are

displayed for the digits.

7

Press and hold the [PRESET] key until [P1] blinks.

8

Briey press the [PRESET] key.

》 [P1] is cleared and registration is complete.

2) Reference point setting

1

Remove any dirt or dust from both the anvil and spindle measurement surfaces and the gage.

2

Bring the measurement surfaces into light contact with each other (or pinch the gage and bring the spindle into light

contact with the gage), stop momentarily, and then apply the appropriate measuring force (see "3. Precautions for

Use

■

Measuring Force").

3

Press the [PRESET] key.

》 [P1] or [P2] blinks, and the registered preset value (zero if not registered) is displayed.

Tips

• Press and hold the [HOLD] key to switch between P1 and P2.

• To change the preset value, see steps

2

through

7

in "1) Reference point registration".

4

Briey press the [PRESET] key.

》 [P1] or [P2] is cleared.

Tips

• The display of this product automatically turns off if not used for 20 minutes or more. To display again, either rotate

the thimble or press the [ZERO/ABS] key.

• If the [PRESET] key is accidentally pressed during measurement, press the [ZERO/ABS] key to return to the former

state. If this does not enable the product to recover, perform "5. PRESET Value (Reference Point) Setting" once

more.

• Do not handle gages (gauge blocks, setting standards for outside micrometers, etc.) with your bare hands. Use

precision work gloves such as cotton gloves.

6. Measurement Method

• Be sure to perform reference point setting before measurement.

• Bring the measurement surface of the spindle slowly into contact with the workpiece. Moving too quickly

could deform the workpiece and affect measurement results.

Gradually and lightly bring the measurement surfaces into contact with the workpiece in the same orientation and

conditions as for reference point setting, apply the appropriate measuring force, and then read the display value

(see "3. Precautions for Use

■

Measuring Force").

5

4

PRESET

PRESETPRESET

7

8

PRESET

PRESET

6

PRESET

PRESET

Key operation icon

=

> 2 s

=

< 1 s

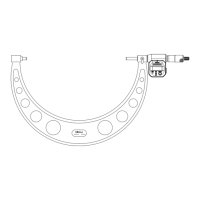

7. Display Unit Angle Adjustment

Turn the bezel to rotate the display unit. After mounting the product, adjust it to an angle which is easy to read.

The display unit can be rotated up to 240° to the right (clockwise) and 90° to the left.

The specication of the display unit does

not allow rotations in excess of the above

angles for the stopper. Exercise caution and

do not rotate beyond the specied range.

This may cause damage.

Do not pull the display unit out or press it in

forcefully. This may cause damage.

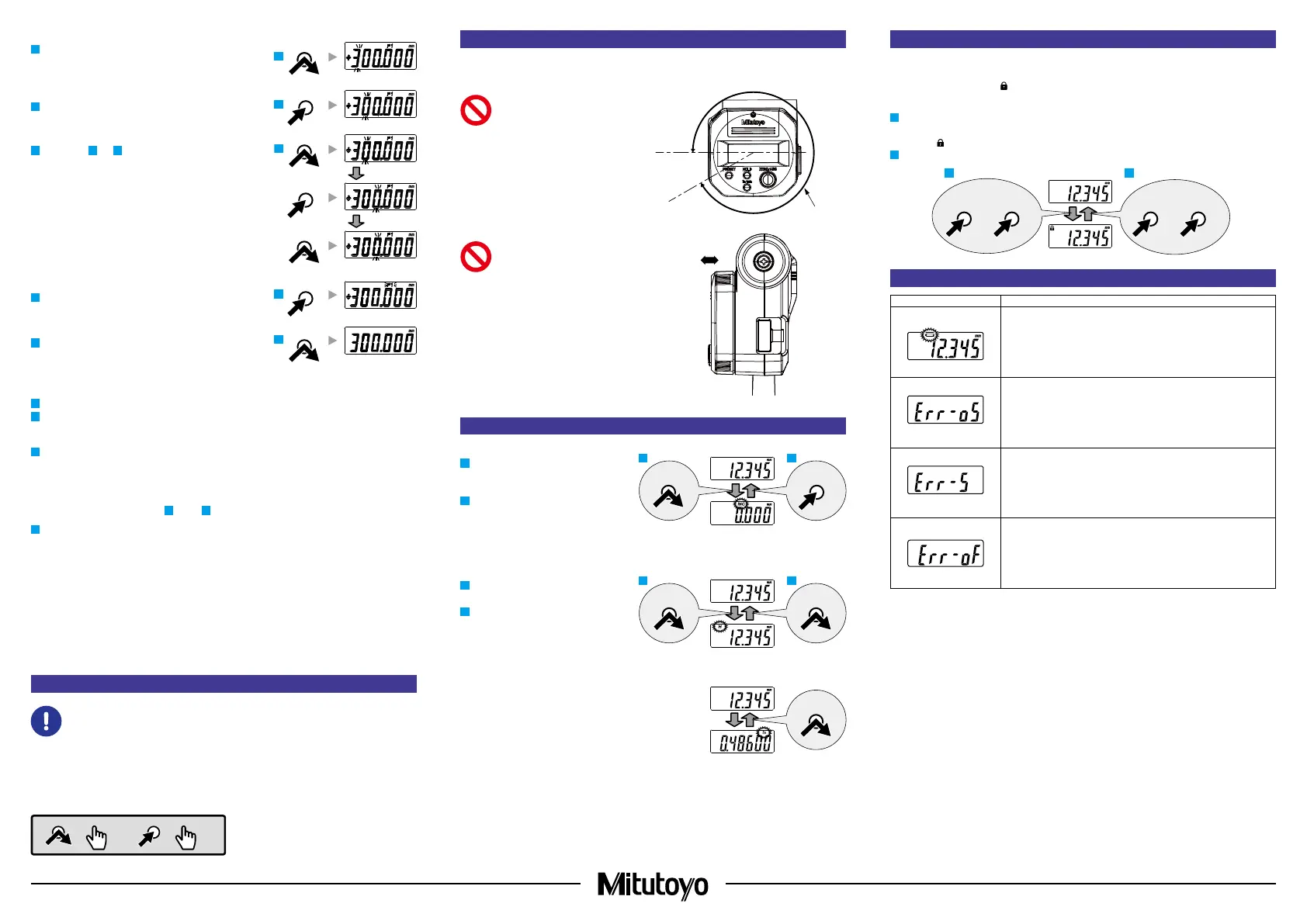

8. Key Functions

■ [ZERO/ABS] Key

1

Briey press the [ZERO/ABS] key.

》 [INC] is displayed, and the display is set

to zero.

2

Press and hold the [ZERO/ABS] key (for at

least 2 seconds).

》 [INC] is cleared, and the length from the

reference point (anvil measurement surface)

is displayed.

■ [HOLD] Key

1

Press the [HOLD] key.

》 [H] is displayed, and the display value is held.

2

Press the key again to release the value.

■ [in/mm] Key (in/mm Products Only)

• Press the [in/mm] key.

》 [in] and [mm] switch back and forth each time the key is

pressed.

330°

ZERO/ABSZERO/ABS

HOLD

HOLD

in / mm

3

9. Function Lock Function (Preventing Accidental Operation)

This product has the Function Lock function, which disables the PRESET function and ZERO/ABS function in order to

avoid accidental changes to the reference point position.

Setting the Function Lock causes [

] on the display unit to light up and disables the [PRESET] key, [ZERO/ABS] key,

and [in/mm] key (in/mm product only), with only the Hold operation function enabled.

1

First press and hold the [HOLD] key, and then additionally press and hold the [ZERO/ABS] key (for at least 2

seconds).

》 [H] and [

] light up in sequence ([H] turns off rst).

2

Perform the same operation to release the Function Lock.

HOLD

+

ZERO/ABSHOLD

+

ZERO/ABS

21

10. Errors and Troubleshooting

Error display Causes and countermeasures

Power Voltage Drop

The battery voltage is low. Replace the batteries promptly.

Counting Error

A counting error has occurred due to excessive speed or noise. Try removing

the batteries and reinstalling.

If it does not recover after being reset, repair is required: please contact the

agent where you purchased the product or a Mitutoyo sales representative.

Counting Error

Initial setting of the control unit failed, or a counting error has occurred due to a

sensor signal error. Try removing the batteries and reinstalling.

If it does not recover after being reset, repair is required: please contact the

agent where you purchased the product or a Mitutoyo sales representative.

Display Overow

The display value exceeds ±999.999. Rotate the thimble in the opposite

direction so that it starts counting again correctly.

Loading...

Loading...