Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8533, Japan

Date of publication: December 1, 2021

Printed in Japan

9. Specifications

Maximum measuring length Maximum

permissible

error

J

MPE *1

25 , 50 mm ±1

μ

m

75 , 100 mm ±2

μ

m

1 , 2 in ±0.00005 in

3 , 4 in ±0.00010 in

Measuring force*2 : 7 N to 12 N

Resolution : 0.001 mm

0.00005 in (in/mm products only)

Display unit : LCD (6-digit and minus sign)

Power supply : Button type silver-oxide battery (SR44 No.938882), x1

Battery life : Approximately 2.4 years

Temperature range : 5

°C

to 40

°C

(operating temperature),

-10

°C

to 60

°C

(storage temperature)

Standard accessories : Wrench (No. 301336), standard bar (equipped as standard with

products with measurement range exceeding 25 mm/1 in)

IP protection level : IP65 (refer to IEC60529 for details).

Dust resistance (level 6) : No ingress of dust allowed.

Protection against water jets (level 5) : Water projected by a nozzle from any direction

shall have no harmful effects.

CE marking/UKCA marking

: EMC Directive/Electromagnetic Compatibility Regulations: EN 61326-1

Immunity test requirement: Clause 6.2 Table 2

Emission limit: Class B

RoHS Directive/The Restriction of the Use of Certain Hazardous Substances

in Electrical and Electronic Equipment Regulations: EN IEC 63000

*1: Maximum

permissible error for indicated value via contact with full measuring face

J

MPE (20 °C).

*2: Measuring force when using the speeder ratchet.

10. Output Function (Function for Type with Output Only)

■ Display Value External Output

The display value can be output to a device by connecting the product (type with output only) and

the external device with a connection cable (option).

■ Connection Cable Installation Method

• Always use the 0-size Phillips screwdriver (No.05CZA619) supplied with the connection cable

(option) when installing/removing screws, and tighten with a torque of 5 to 8 cN·m or so.

Tightening with a high torque could cause damage.

•

When connecting the connection cable, ensure that the connector gasket does not protrude.

If the connector gasket is not installed properly, waterproof functionality may decrease and lead

to malfunctions.

Tips

Note that using this product in a location with high noise may cause malfunctions (flickering or

errors).

1

Use the Phillips screwdriver supplied with the connection cable to remove the cover fixing

screws (M1.7 x 0.35 x 2.5, No.09GAA376).

2

Remove the cover.

3

Check that the connector gasket (No.04AAC126) is correctly installed at the proper position

(do not remove the connector gasket).

4

Mount the connection cable plug.

5

Hold the plug manually so that there is no gap between the plug and the connector on the

micrometer body, and fasten using the fixing screws on the connection cable.

Connector gasket

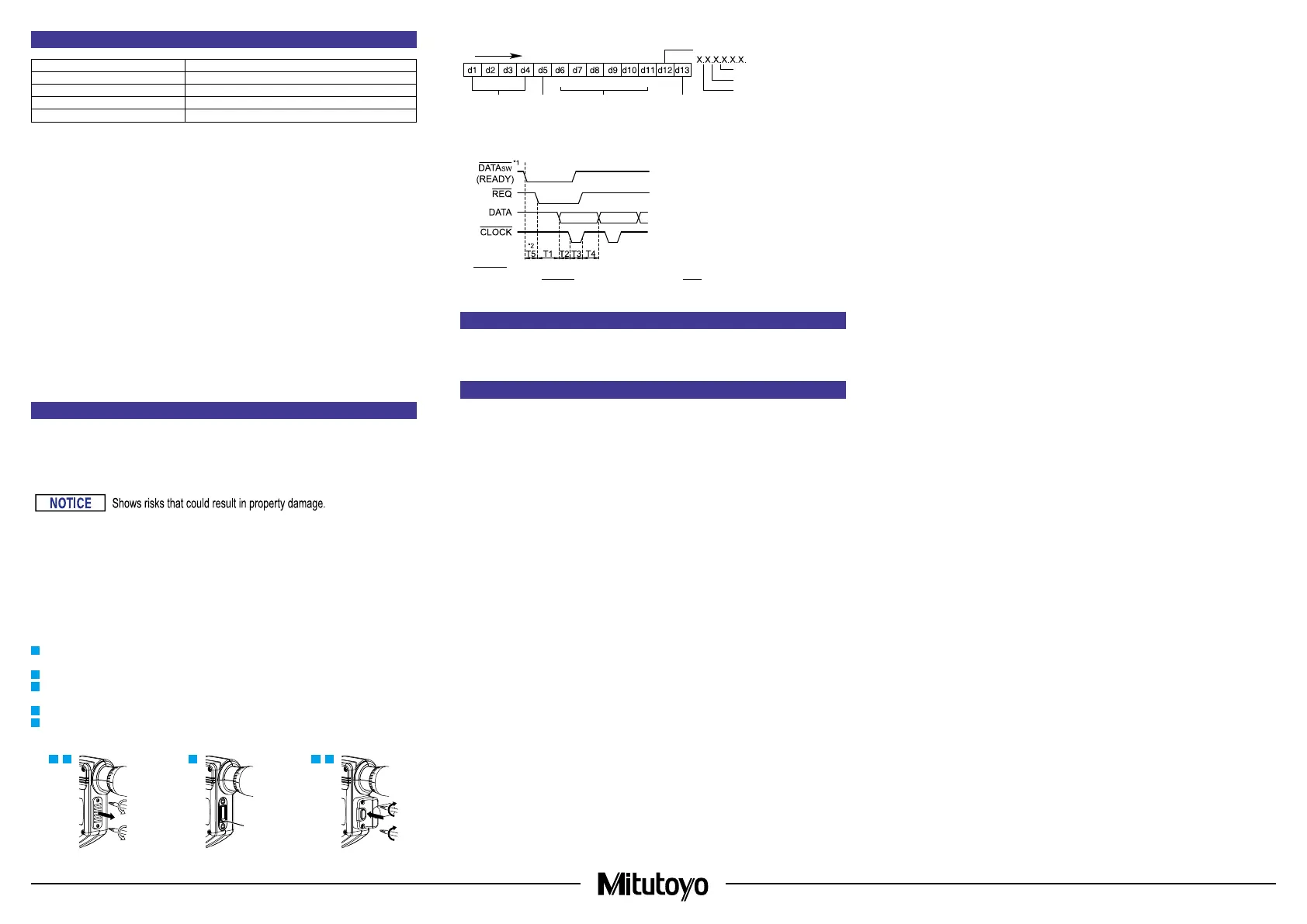

■ Output Data Format

(1) Output order

(2) All "F"

(3) Sign

(4) Measured

value

(5) Decimal point

(6) Unit

MSD LSD

(2)

(1111)

(4)

(3)

+:0(0000)

3(1100

4(0010

5(1010

(6)

mm:0(0000)

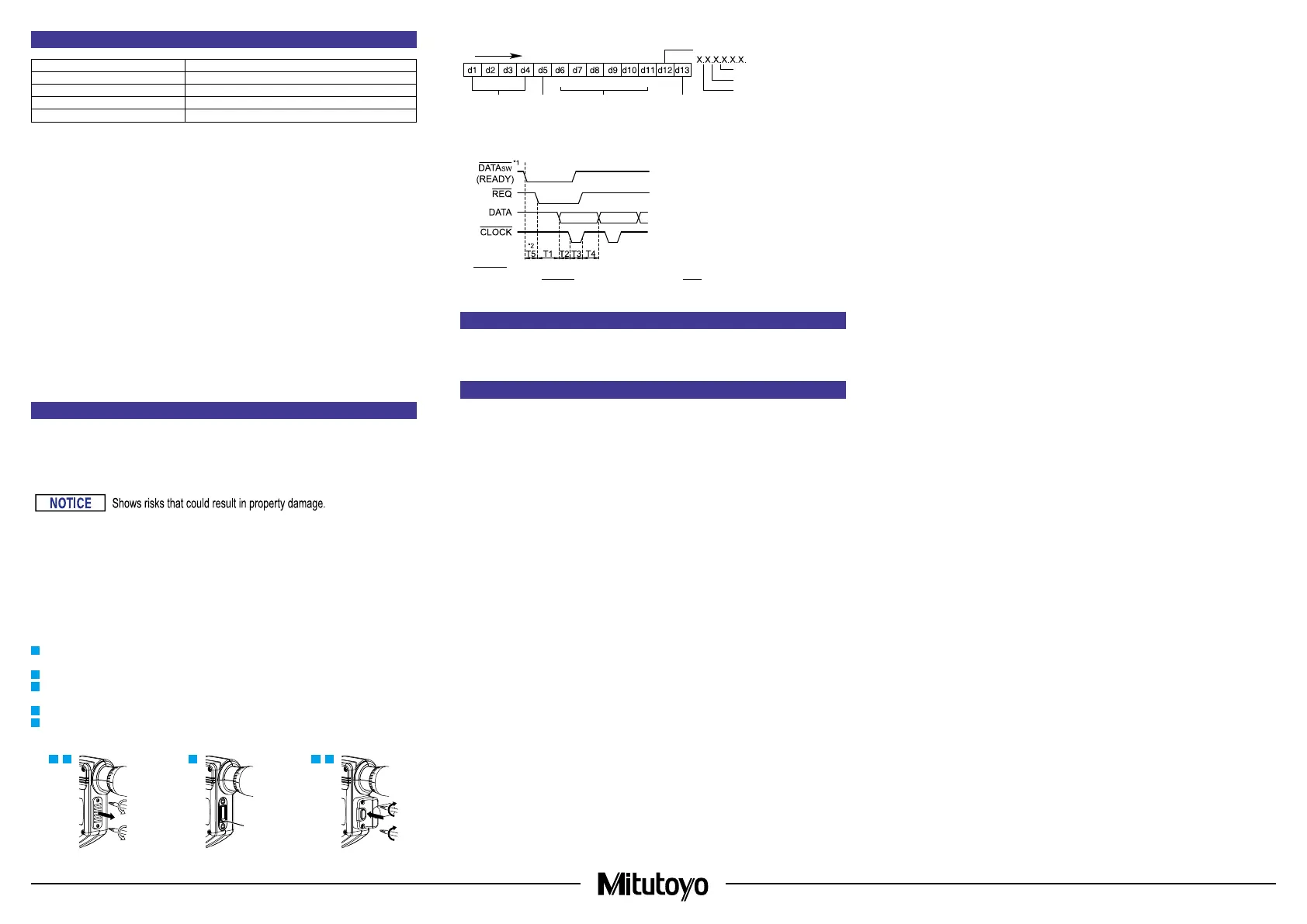

■ Timing Chart

0 ms ≦ T1 ≦ 200 ms

0.11 ms ≦ T2 ≦ 0.14 ms (Typ: 0.122 ms)

0.11 ms ≦ T3 ≦ 0.14 ms (Typ: 0.122 ms)

0.22 ms ≦ T4 ≦ 0.27 ms (Typ: 0.244 ms)

T5 ≦ 80 ms

*1: DATAsw is LOW while the data output key is being pressed.

*2: The time T5 until DATAsw goes to the LOW level and REQ

is input is determined by the data

processing device performance.

11. Options

• Connection cable: No.05CZA662 (1 m)

• Connection cable: No.05CZA663 (2 m)

For options other than the above, refer to the General Catalog.

12. Off-Site Repairs (Subject to Charge)

Off-site repair (subject to charge) is required in the case of the following malfunctions. Please

contact the agent where you purchased the product or a Mitutoyo sales representative.

• Faulty spindle operation

If the spindle is scratched, these scratches may interfere while the spindle is retracting, causing

faulty operation.

Operation may also suffer if the spindle is rusted.

• Inconsistent measured values

If there are burrs or nicks generated by an impact on the measuring surfaces, it may affect

measurement repeatability.

• Count value error/faulty operation

If the thimble of this product is retracted too far, the internal sensor will be damaged. This may

cause count errors or faulty operation.

3

Loading...

Loading...