MK-101 w/JCS Stand Revision 04/05, Effective Date August 19, 2005

Page 34

MAINTENANCE AND TROUBLESHOOTING

4. V-Belt Inspection, Adjustment and Replacement:

The MK-101 is designed with a power transmission V-belt. In order to ensure the MK-101 operates at peak

efficiency, the V-belt should be inspected monthly, and changed if the V-belt shows damage and/or excessive

wear.

NOTE: 1. When a new belt is installed, it should be inspected and re-tensioned after the first forty-eight (48) hours

of operation.

* A GFCI wall socket is the preferred protective device.

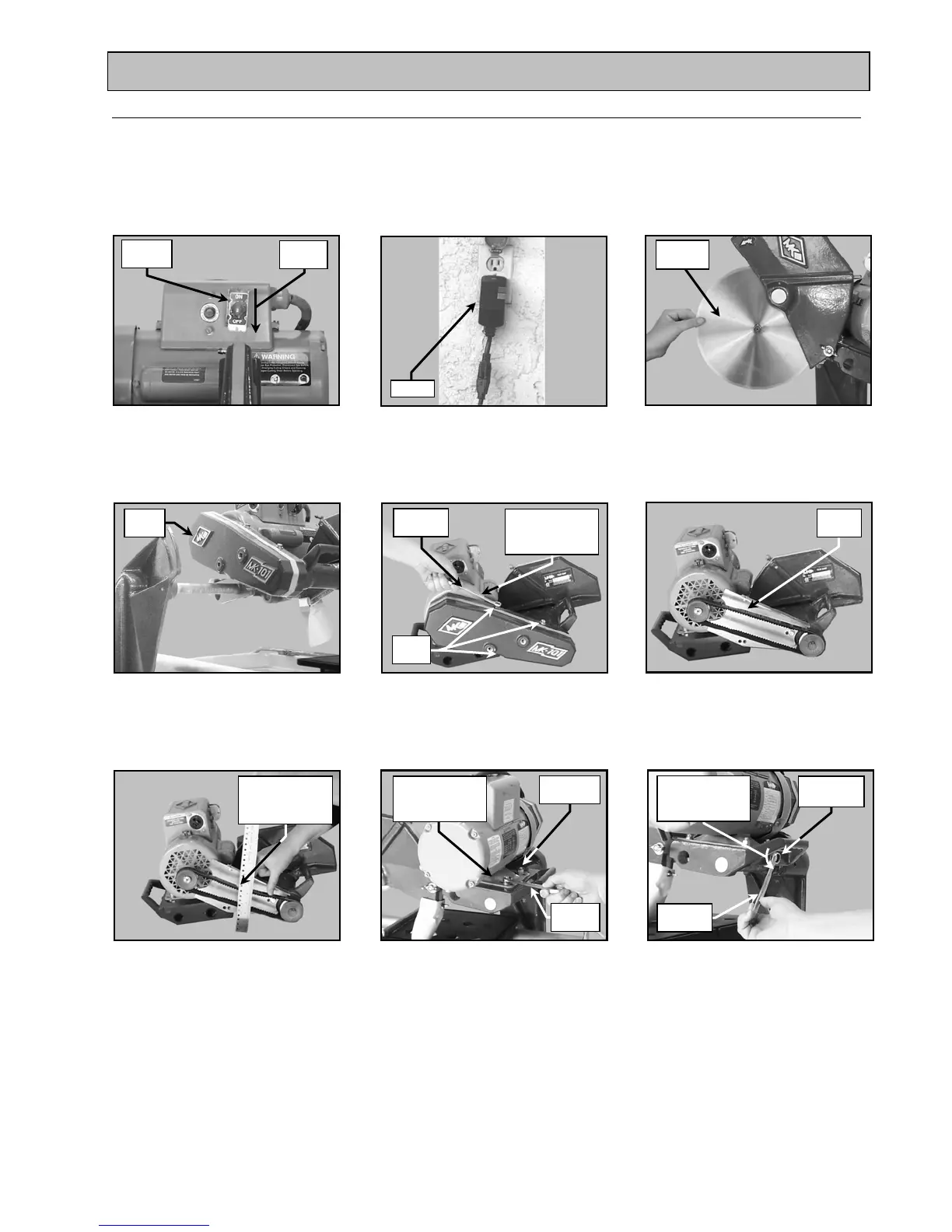

Inspect

V-

el

Off

Position

ON/OFF

Switch

(D)

Remove the Cutting Head (See

Adjusting the Cutting Head

(I)

Loosen the Motor Adjustment

Strap

(H)

Loosen the motor mounting bolts, i

re-tensioning only go

to step N

(G)

Check the belt for proper tension

if tension is correct, go to step R

(proper tension 1/8-inch)

(F)

Inspect the V-belt for cracks,

Fraying, separation and wear. Go to

step H if replacement required

(E)

Remove the Belt Guard

(A)

Ensure the ON/OFF Switch

is in the OFF position

(B)

Unplug the GFCI from the Power

source*

(C)

Remove the Diamond Blade

Diamond

Blade

Retaining

Bolts

Unplug

Cutting

Head

Three

Bolts

Rotate Counter-

clockwise to

loosen

7/16-inch

Wrench

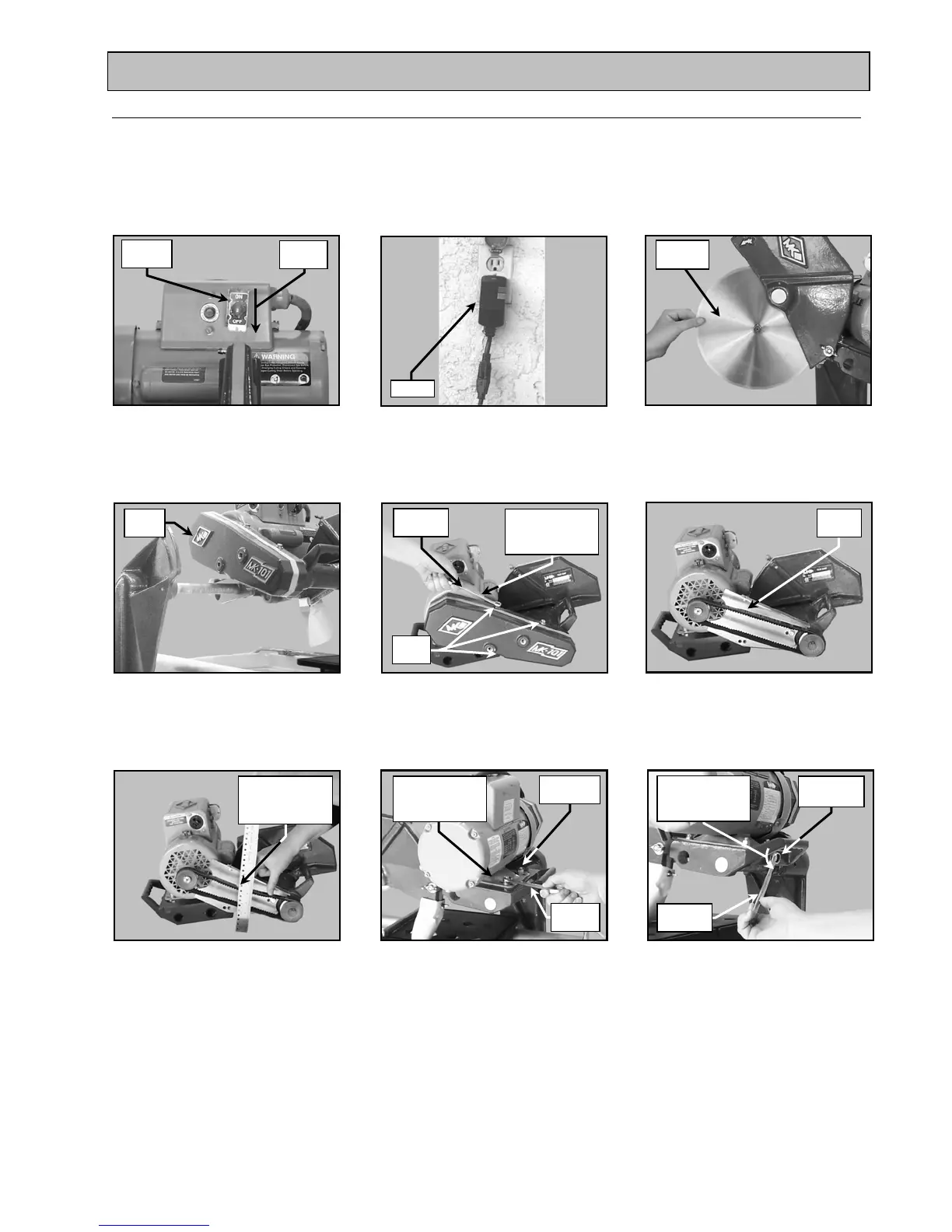

Check Tension

1/2-way

between pulleys

Rotate Counter-

clockwise to

loosen

9/16-inch

Wrench

Adjustment

Strap Bolt

Rotate Counter-

clockwise to

loosen

1/2-inch

Wrench

Loading...

Loading...