2. Center Keel Assembly

The first step in constructing the hull is

to assemble the laser-cut center keel.

With a sharp pencil, mark the reference

line and bulkhead stations on both sides

of the center keel. Be especially critical

when locating the reference line; it is a

key to proper alignment. Measure from

several points on the plans.

Lay a sheet of waxed paper or plastic wrap

over a flat building board or table, and

place the center keel halves on top. Affix

the joints with white or woodworker’s

glue. Use a steel or aluminum straightedge

to align the reference line. If necessary, add

weights to hold down the parts. Let the

adhesive dry at least overnight, preferably

24 hours (Figure 1-1).

3. Installing the Sternpost

The keel and stem are part of the center

keel, but the sternpost is a separate

piece. Taper the sternpost per the plans

and glue in position.

Option: Cut the rabbet before installing

the sternpost

.

4. Cutting the Rabbet

Measuring from the P-O-B plans, mark

the rabbet and bearding lines on both

sides of the center keel with a pencil. At

the stern and bow, cut a 1/16” deep rab-

bet with a hobby knife. Now, using a

1/8” wide chisel, start at the bearding

line and cut toward the rabbet. The

1/16” thick hull planking must lie flush

against this cut area. Figure 1-2 shows

how the rabbet changes at midship. To

help judge the angle of the rabbet, posi-

tion a scrap piece of plank against the

keel as you cut.

5. Tapering the Stem

Taper the stem according to the plans.

6. Installing the Bulkheads

Laser

-cut bulkheads include timber

-

heads. These extend above the deck to

form bulwark stanchions. Compare the

bulkheads with the patterns on Sheet 1,

determine which is which, and label

them

A through O. Test each to make

sure it slides into the center keel slots.

If the fit is too tight, sand the slots.

Bulkheads should fit snugly with a little

tolerance for glue.

Using a pencil, mark the r

efer

ence line

on every bulkhead. It must align with

the reference line on the center keel.

This assur

es an accurate hull with each

bulkhead correctly related to the others.

Next, use a tick strip to transfer the

bevels from the plans to the bulkheads.

Mark them in pencil. Cut the bevels

with a #1

1 hobby blade (Figur

e 1-3).

Deck bevels and side bevels near amid-

ships are diminutive. Barely perceptible

ones ar

e sanded in after the bulkheads

are installed.

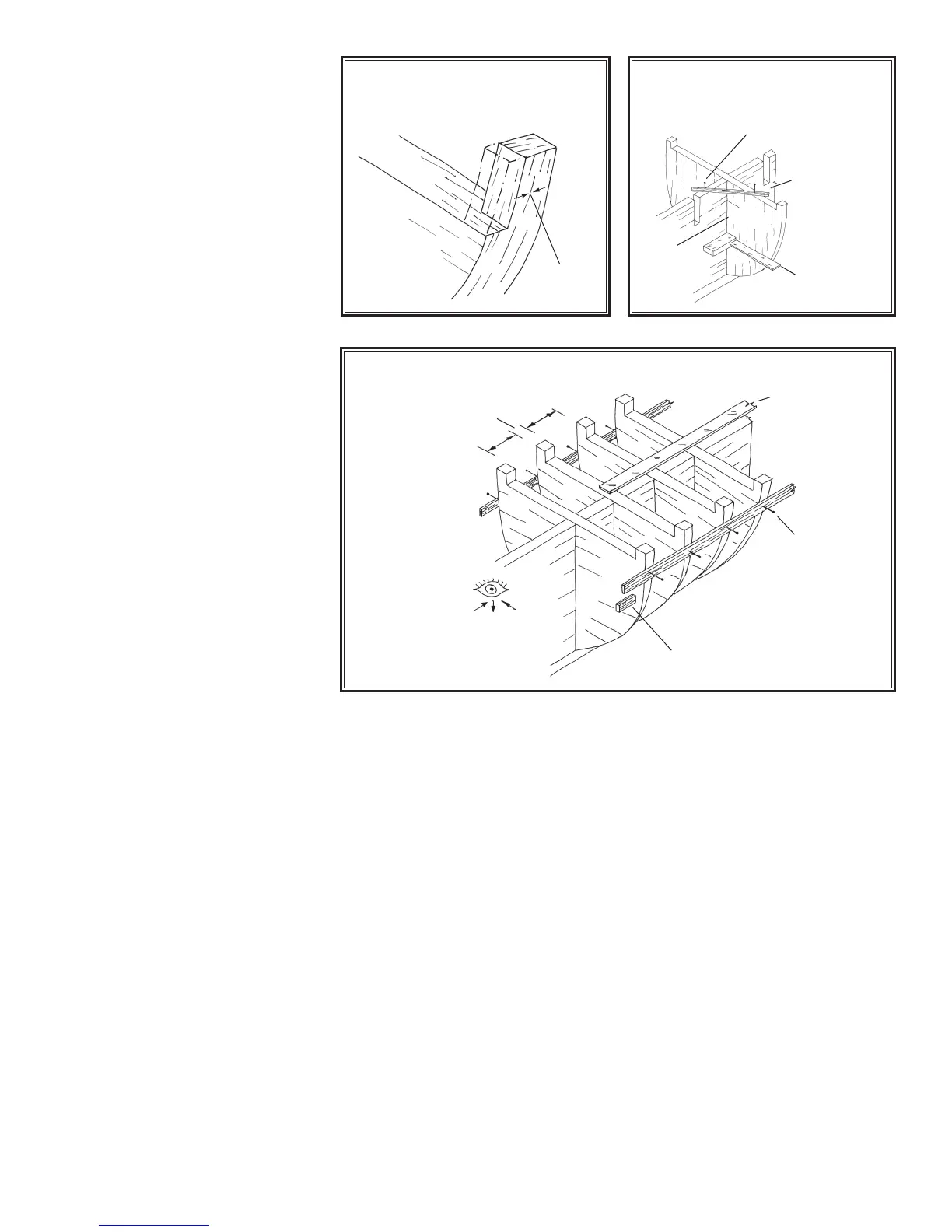

Bulwark stanchion extensions: Bulkheads

are 3/16” thick, but the stanchion exten-

sions should be 1/8”, so cut them back

(Figur

e 1-4). Stanchions between bulk

-

heads are added in Step 14.

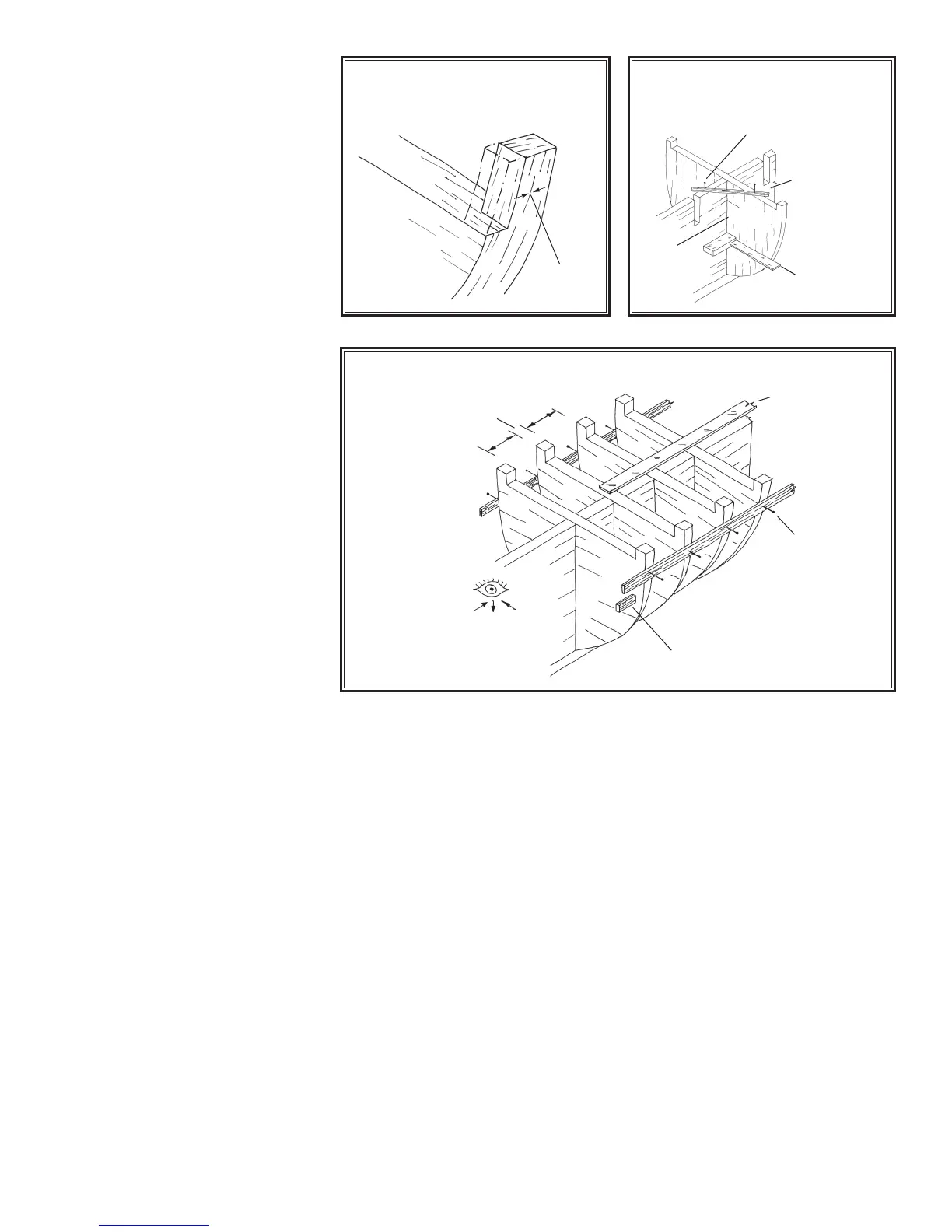

Glue the bulkheads in place. Make sur

e

their reference lines match the one on

the center keel. Use a small machinist

square to set each bulkhead perpendicu-

lar to the center keel, then tack or tape a

temporary strip to the top of the bulk-

head to hold it in place while the glue

dries (Figure 1-5).

Model Expo sells the Fair

-A-Frame

Building Slip (Ms 105), a device that

holds the center keel steady and bulk-

heads perpendicular to it. Purchase it

separately.

Once the bulkheads ar

e installed, tack or

tape a temporary batten to the sides of

the hull just below the deck (Figure 1-6).

This is a critical step. Measur

e the spac

-

ing between each port and starboard

bulkhead and r

etack the battens until the

hull is aligned. Although the center keel

was assembled flat, it could warp and

produce a banana-shaped hull. When it

looks corr

ect, check it again.

Option: When the hull is aligned, add

permanent str

uts between bulkheads

close to the exterior, then remove the

battens. Now examine the bottom of

11

Cut to 1/8”

Fig. 1-4 Forming Bulwark

Stanchions

Fig. 1-5 Gluing Bulkheads

to Center Keel

Pin or Tape

Temporary

Wood Strip

Square

Glue

Fig. 1-6 Temporary Battens for Hull Alignment

Check Spacings

Check Keel With

Straight Edge

Tack Temporary

Strip Both Sides

Optional Permanent Strut

Between Bulkheads

Check Alignment Visually in

All Directions

Loading...

Loading...