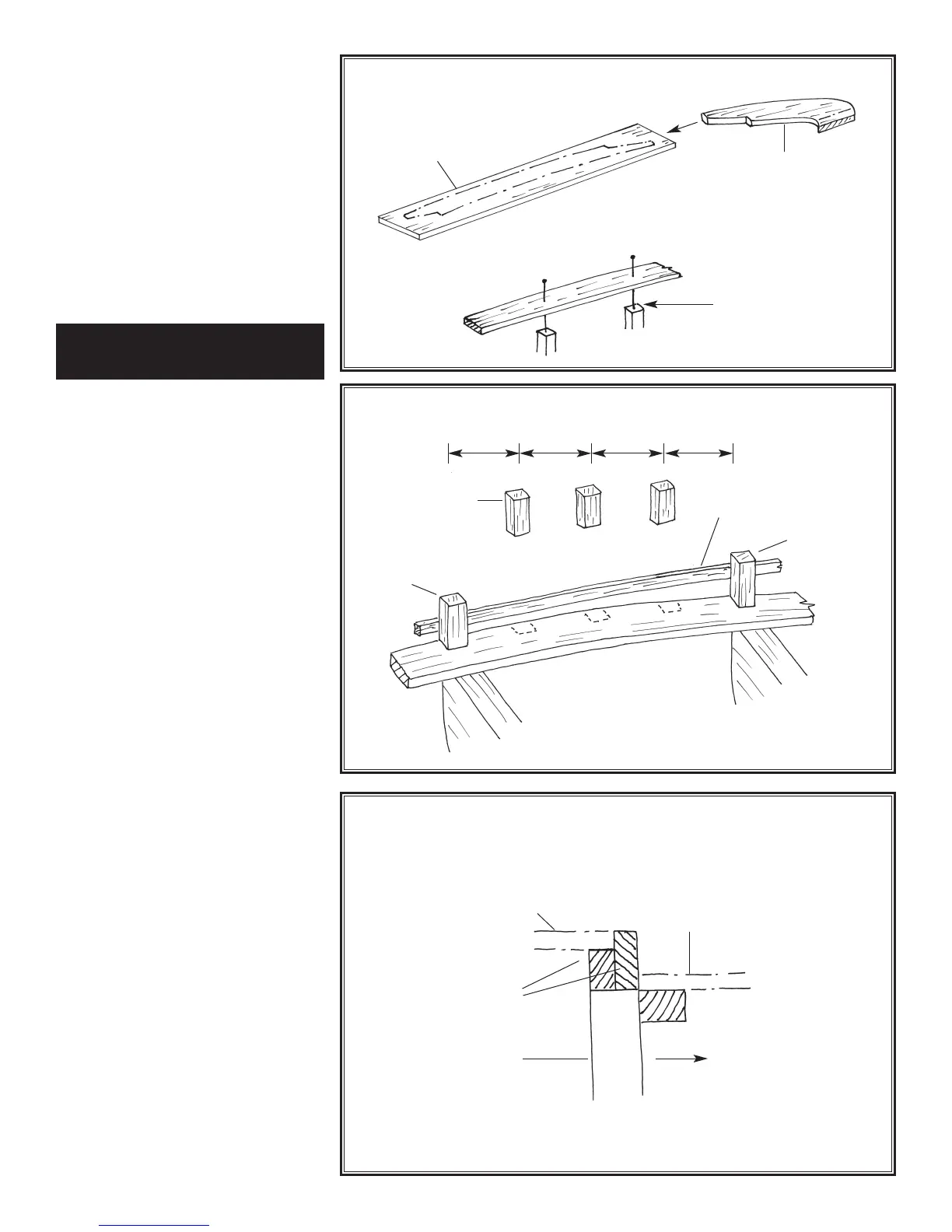

15. Installing the Great Beam

& Deck Beam

The great beam (two laser-cut pieces)

at the quarter deck step sits atop

Bulkhead H. Glue the laser-cut deck

beam forward of

Bulkhead H. This

beam provides a landing for the fore

deck planking (Figure 1-15).

That completes the basic hull framing.

Touch up rough spots with sandpaper.

Consider painting the bulwark

stanchions before continuing.

Planking the

Plank-On-Bulkhead Hull

Here are some shipbuilding terms used

in the planking process.

Plank: Single length of wood used to

plank a hull or deck. A

strake is a contin-

uous line of planks from wherever it

begins to where it ends.

Garboard: Planking strake adjacent to

the keel.

Sheer strake: Upper line of planking on

a hull.

Wale: Heavy layer of strakes below the

sheer strake.

Bluenose has no wale.

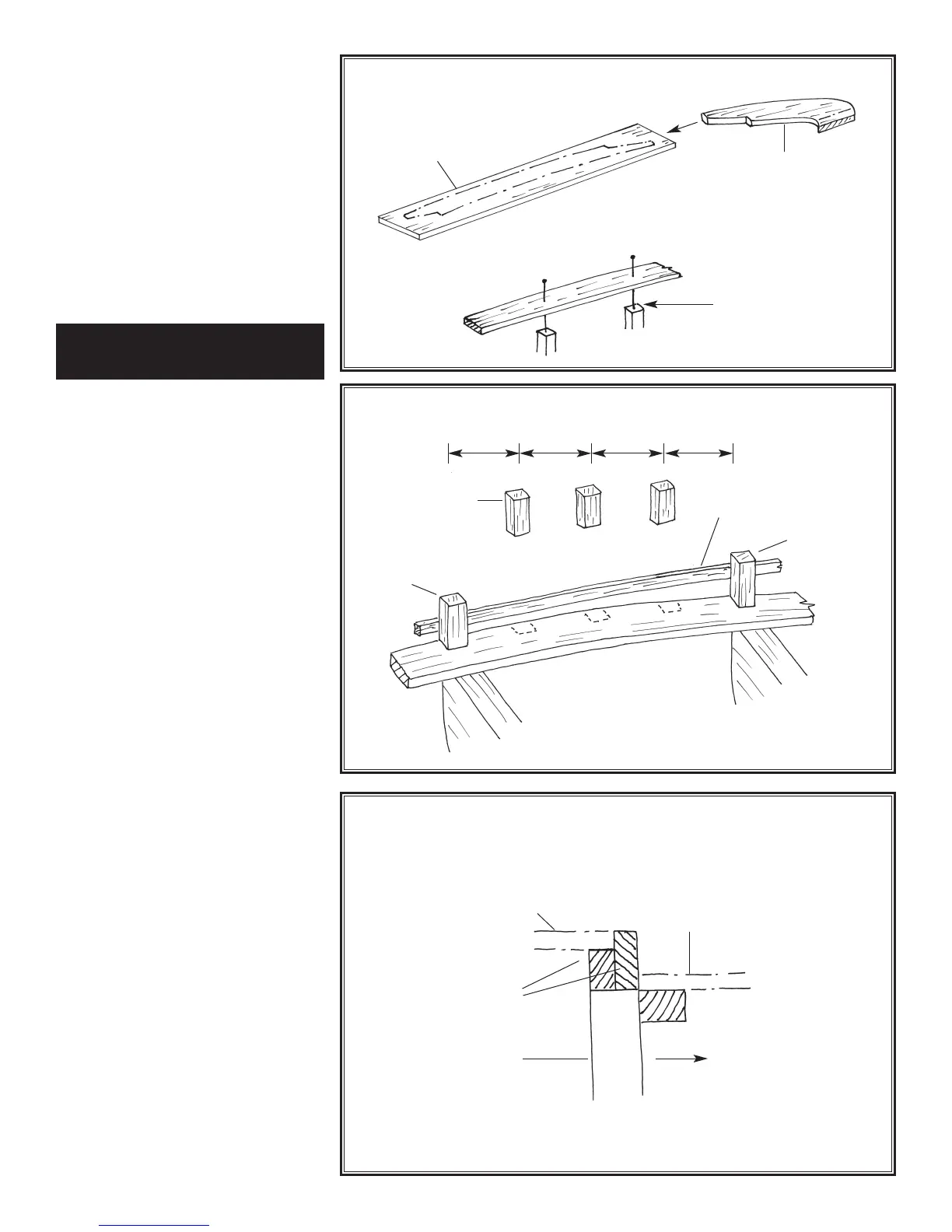

Belts: Group of planks along the hull.

Belts are laid out using

battens (tempo-

rary strips of flexible wood).

A

ribband is

also a batten. It holds frames in position

during planking. Ribbands are removed

as planking is completed.

Spiling: Process for marking and cutting

a plank to a given shape.

Edge-bending or springing: To bend a

plank edgewise.

Fair: Refers to smooth, gradual curves

when planking.

Nib or nibbing: Eliminates the tapered

edge of one plank from running into

another at a sharp angle by squaring off

the pointed end and inserting it into a

notch in the following plank. Nibbing

generally applies to decks, but some

-

times hull planks are nibbed.

Fig. 1-13 Installing The Main Rail

Fig. 1-14 Installing Fake Bulwark Stanchions

Fig. 1-15 Great Beam & Deck Beam at Step

Laser Cut

Pin & Glue

BHD

Deck Plank

Deck Plank

FWD

Laser Cut Beams

Bulkhead H

BHD

Fake Stanchions

Batten to Help

Alignment

Cut From

Wide Strip

14

Stage 2

Equal Spaces

Loading...

Loading...