bulk head templates. These were made

using the plans as a guide to shape them.

Trace the design on a 1/32” thick bass

wood sheet and cut them free with a sharp

blade. Glue them into position. Two addi-

tions strips of 1/32” x 1/8” planking were

glued along the front edge of each bulk

head to simulate the columns you see in

photo #4

Step 5 – The false decking can now be

placed on top of the beams to complete the

extension of the half deck. They are laser

cut for you. It is easier to put the false

deck into position using two pieces. They

approximate the shape of each half need-

ed. Because there may be minor fluctua-

tions with the positions of the bulwark

stanchions you will have to notch them out

of template. Simply rest one half of the

decking on the beams and mark the loca-

tions for each of them. See photo #5.

Once both false deck pieces are glued into

place run a bead of glue down the seam

between each half. Draw the center line

down the length of the half deck in prepa-

ration for final planking. The positions for

the two hatches should be transferred on to

the deck as well. See photo # 6.

Step 6 – When you planked the other

decks on the model you added the water-

way along the bulwarks after the planking

was finished. There were no bulwark stan-

chions on the model yet. Planking around

the bulwark stanchions could be a difficult

and tedious job. Therefore we will add the

waterway now in order to make planking

the half deck easier.

This time you will use a planking strip that

is 1/16” thick x 1/8” wide. This is twice

as thick as the waterway used earlier.

Once the 1/32” thick deck planking butts

up against the waterway, the waterway

will appear to be the correct thickness.

Take a length of this thicker planking and

notch out the bulwark stanchions the same

way you did for the false decking. Glue

these into position. Do not add the water-

way on the forward edge of the half deck.

This will be added after the deck is

planked. See photo #7.

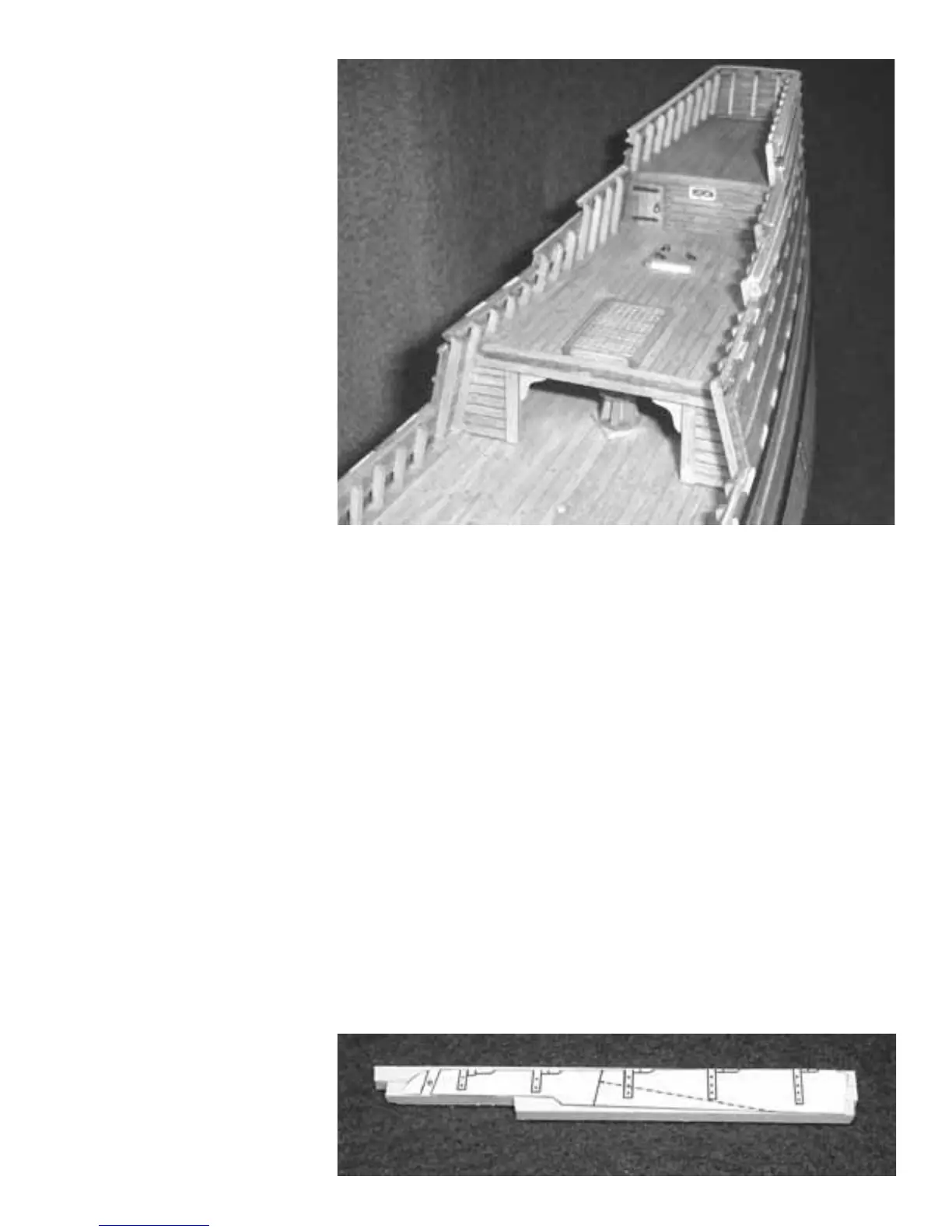

Step 7 – Now you can plank the deck as

you did the others for the model. Create

and install the hatches first. Plank around

them. See the plans for any details. The

coaming or frame for each hatch was made

first using 1/8” x 1/16” Bass wood strips.

The grating is added to finish off the larger

hatch. If the capstan ever needed to be

replaced it would have been hoisted up

through this larger hatch. The smaller

hatch in front of the mizzen mast does not

have a grating. Simple planks (cover

boards) were fitted with handles instead.

They are made using the eye bolts and

split rings supplied with the kit. Photo #8

shows the quarter deck completed. Note

the waterway added to the front edge of

the quarter deck. It is the last wood strip

(1/32” x 1/8”) needed to complete this step

in the project.

Making the Rudder...

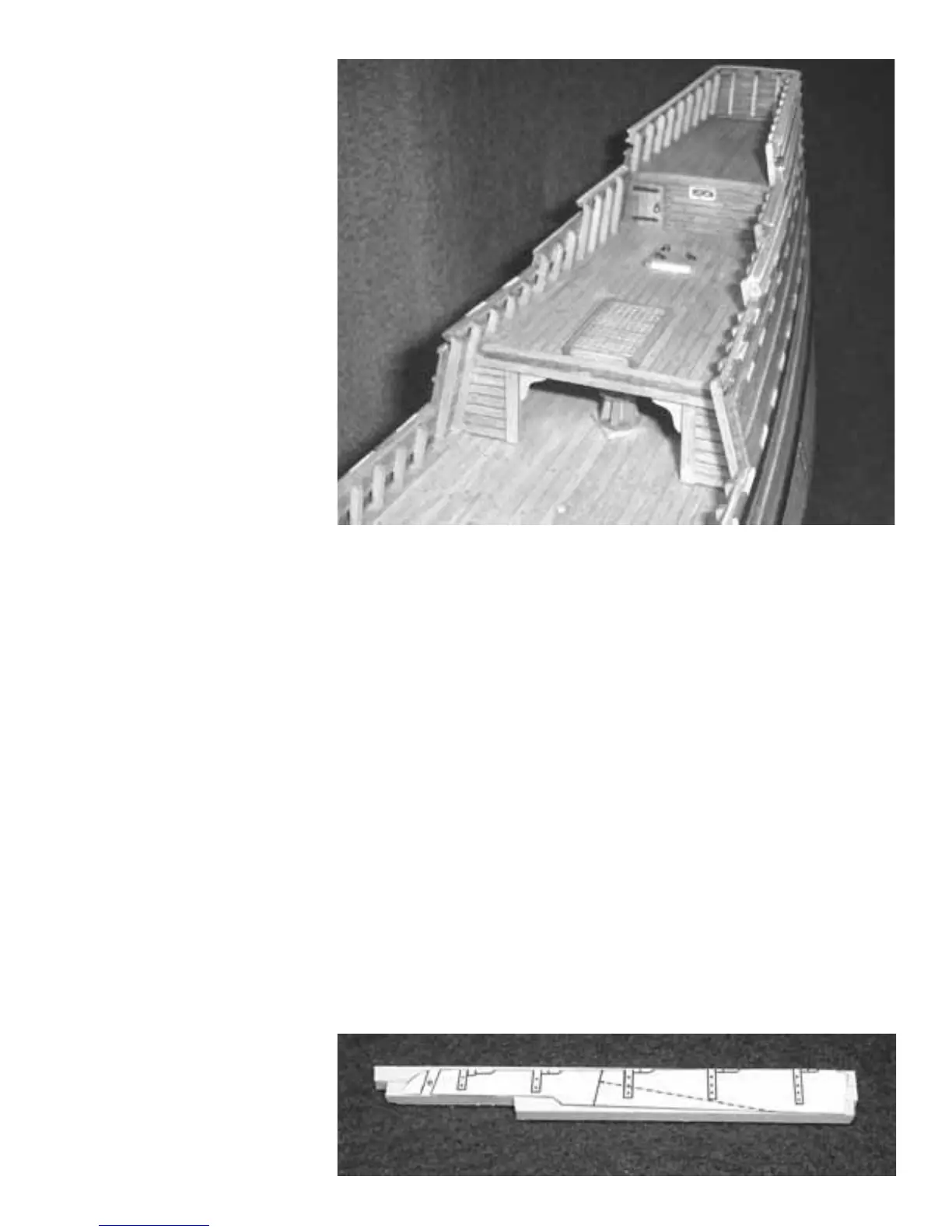

Take 3 lengths of the 1/8” x 1/8” strips

supplied and glue them together edge-to-

edge. Paste a photo copy of the rudder on

the top of it and cut it to shape with a

sharp blade. See the photo below.

The photos (1A & 1B) on the next page

show the rudder after it was cut to shape

with a sharp #11 blade. It was sanded

afterwards.

The rudder is attached to the stern post

with hinges called “pintles and gudgeons”.

These are the two halves of each hinge.

The pintle being that which is attached to

the rudder and the gudgeon is attached to

the hull.

The brass strip supplied with the kit can be

used to make the gudgeons and pintles

The photos on the next page show you

how to create the gudgeons and pintles.

The brass strip should be cut into 10

smaller lengths. See the plans for the

approximate sizes. The 10 strips were then

bent around a block of wood that was the

same thickness as the rudder (1/8”). This

created the final shape for our gudgeons

and pintles. They are identical except the

pintles will have a small length of 22

gauge wire glued into the inside of them.

The rudder is painted white below the

wales. Paint the first coat before gluing

the pintles into position. The pintles are

Photo #8

24

Loading...

Loading...