47

CHANGING TO A DIFFERENT TYPE OF GAS.

Should a different gas be used from the gas for which

the boiler has been equipped, the following parts

must be replaced.

● Burner injectors (12 MCB2149).

● Burner pressures must be adjusted.

These modifications, together with the regulating

process, must be carried out by a qualified Corgi

registered engineer.

● Remove the front cover.

● Remove the room sealed cover, (8 screws).

● Unscrew the 4 screws from the electronic box, (2

screws on the front and 2 at the bottom of the unit).

Move the electronic box down.

● Remove the ionisation and spark electrodes.

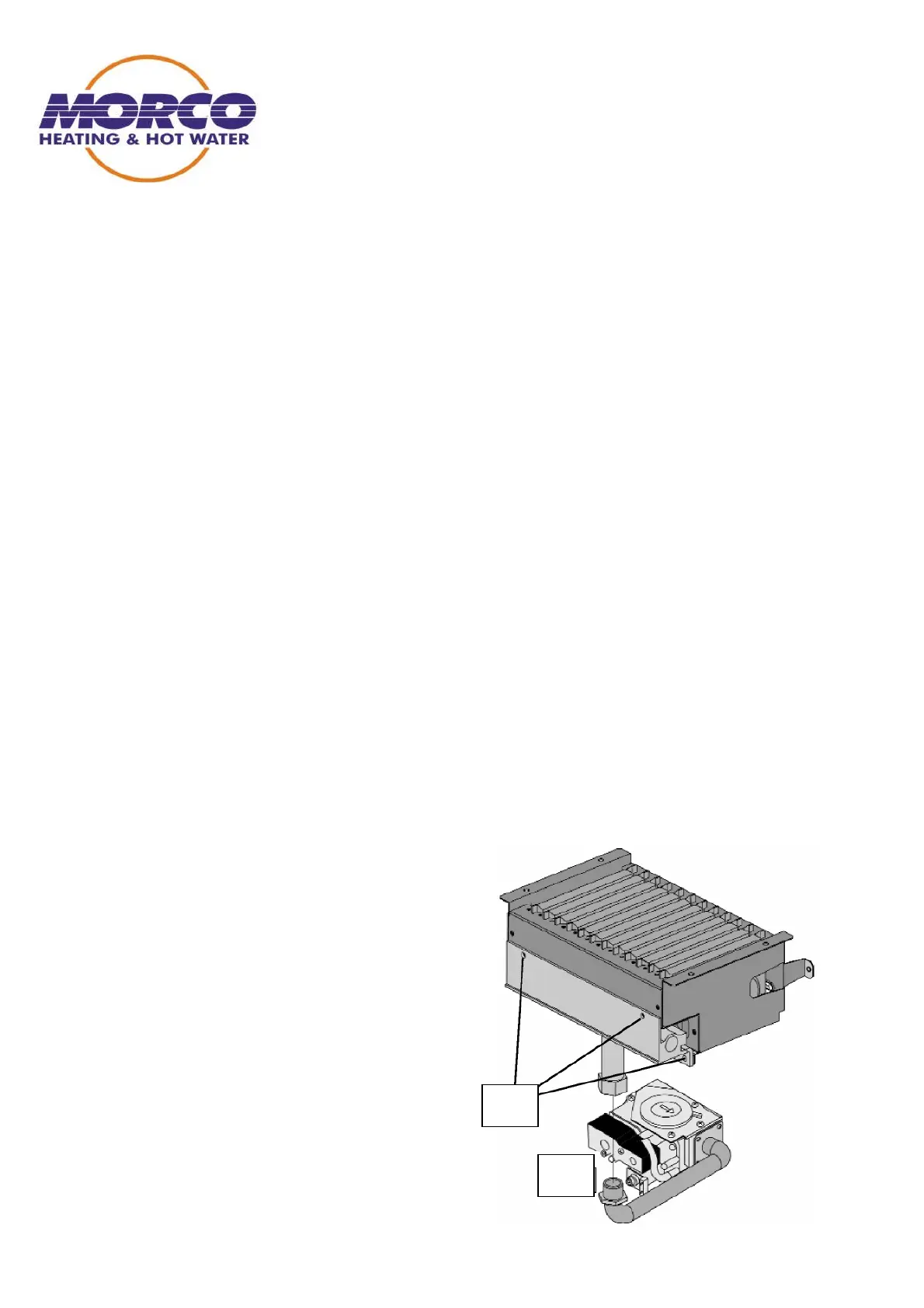

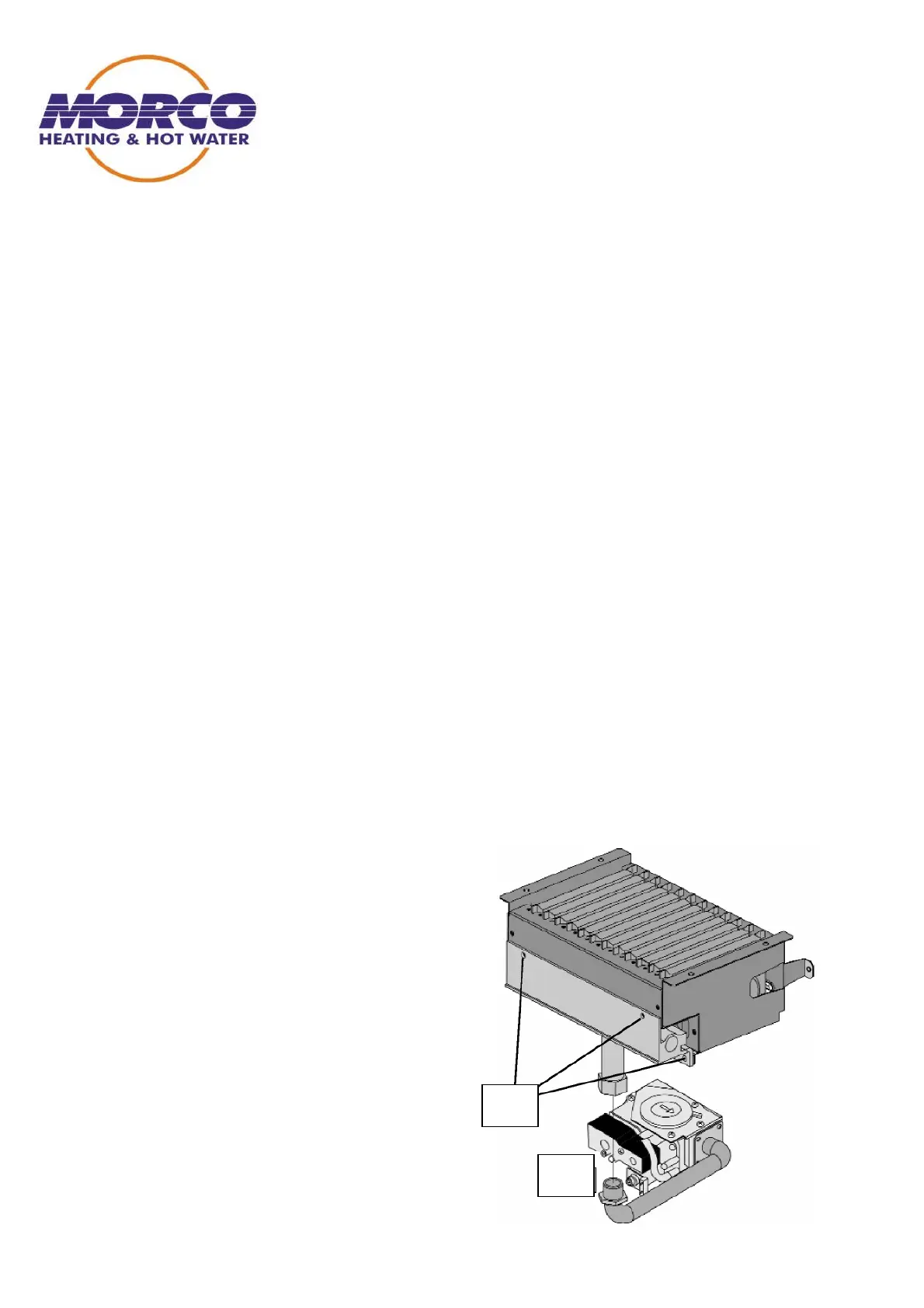

● Unscrew the hexagonal nut (B) which holds the

manifold to the gas valve, (figure 1).

● Unscrew the 4 screws (A) which hold the manifold

onto the burner. Remove the manifold, (figure 1).

● Change 12 burner injectors (E), (figure 2).

● Refit the manifold, ionisation & spark electrodes.

Reconnect the manifold to the gas valve (B). Refit

room sealed cover.

● To adjust the burner pressures to the new type of

gas, proceed as follows:

● Remove the plastic cap (D) of the electronic box.

The bridge S4: (figure 7).

- for LPG must be bridged.

- for Natural Gas must be un-bridged.

● Remove the clear plastic cap (C) (figure 4) from

the gas valve and run the boiler in DHW mode.

Set the maximum burner pressure:

● Set the DHW temperature to maximum.

● Adjust the variable resistance (P1) to maximum,

(rotate fully clockwise), (figure 7).

● Open a hot tap.

● Adjust the maximum burner pressure (chart 1).

Using a 10mm spanner rotate the nut (E) of the gas

valve (figure 5). Rotating clockwise increases the

burner pressure.

● Adjust the variable resistance (P1), rotating it anti-

clockwise until the burner pressure starts to drop.

Set the minimum burner pressure:

● Open a hot tap.

● Disconnect one of the modulating electro valve

terminals on the gas valve.

● Adjust the burner pressure to the value indicated in

chart 1. Holding hexagonal nut (E) with the spanner,

rotate the star screw (T). Rotating clockwise will

increase the pressure and anti-clockwise will decrease

the pressure.

Once the pressure is set, reconnect the terminal.

Set the ignition pressure:

● Adjust the ignition pressure on variable resistance

(P2), rotating clockwise increases the pressure and

anti-clockwise decreases the pressure (chart 1). To do

this you must do the following:

● Disconnect or remove the ionisation electrode.

● Turn on the boiler and during ignition, (when

sparking) adjust the variable resistance (P2) to the

correct value, (chart 1).

● Reconnect or refit ionisation electrode.

● To regulate the maximum heating output, you

adjust the variable resistance (P3). To do this the

boiler should be working in heating mode on

maximum temperature. Rotate (P3) clockwise to

increase pressure and anti-clockwise to decrease

pressure, (chart 1).

Note: The central heating power is factory set at

70% of its maximum.

● Refit the clear plastic cap onto the gas valve.

IMPORTANT: When finished, make sure the outlet

burner pressure nipple is fitted.

A

B

Loading...

Loading...