14

15

DK ENG

3.0 Maintenance

The maximum recommended weight of wood fuel per load is 2 kg/h/5.5Ibs (approx 3 split

logs).

Under normal ring, the average ue temperature in the stove pipe, measured 20 cm above

the stove, is approx. 300° C (550°F). The maximum ue temperature in the stove pipe must

not exceed 450° C (750°F). If the ue temperature exceeds 450°C (750°F), it is considered

as over ring and may cause premature wear and tear of the stove.

To help gauge the correct running temperature of your stove, we recommend you use the Morsø

Flue Gas Thermometer (part # 62901200). The Flue Gas Thermometer magnetically attaches onto

the stove pipe approx 20 cm (8”) above the stove’s top plate and measures the surface temperature

of the stove pipe. Please see your authorized Morsø Dealer for availability.

Draft conditions

If smoke or fumes come out of your stove when lightning up and reloading, or if the re simply

will not respond, a poor draft is almost certainly to blame. (In a very few cases, there may be

insucient fresh air getting into the room - see installation advice above). Take advice from

your stove supplier on how best to upgrade your ue system to improve draft.

Rules of woodburning

If you want less heat, put fewer logs on the stove and reduce the amount of air. It is still impor-

tant to maintain a good layer of embers.

- Less heat - less wood - less air

- Greater heat - more wood - more air

- Soot deposits will settle on the glass if the stove is run too slowly or if your wood is not

well seasoned.

Carbon monoxide detectors

It is required in some jurisdictions to install smoke and carbon monoxide detectors where

heaters are installed. Install at least one smoke detector on each oor of your home

to ensure your safety. It should be located away from the wood appliance and close to

the sleeping areas. Locating a smoke detector too close to a wood appliance can cause the

smoke detector alarm to sound if a pu of smoke is emitted while the wood appliance door

is open during reloading. Follow the smoke detector manufacturers placement, installation,

and maintenance instructions

Revisions

Rev.

Sign.:

Title:

Drawing no.:

1:1

1410 NA

Morsø 1400

RSV

28.04.2010

A2

Exploded Diagram

Date of print: 28-04-2010

U:\udv\Tegninger\1400\1400 Samlingstegning.SLDASM

1400-347 a

-

Itemno.:

This drawing is Morsø Jernstøberi A/S' property and must not be sold, lended or copied without any written authorization from the company.

Material:

Weight:

Model no.

Drawingtype:

Location of file:

Scale:

Format:

Released:

Construction:

Date:

When perfoming maintenance on your stove, always protect yourself, using safety goggles

and gloves.

3.1 Exterior Maintenance

The stove surface is painted with heat-resistant Senotherm paint. It is best kept clean by

vacuuming with a soft brush attachment or by wiping with a lint-free cloth.

Over a period of time, the painted surface may become slightly grey. A can of Morsø touch-up

spray paint should be available from your stove supplier. This can be applied - in accordance with

the instructions - in just a few minutes. When rst ring after touching up, the stove will give o

a slight smell as the paint cures. Make sure to ventilate the room well during this phase.

3.2 Internal maintenance

Glass

If the stove is generally run at the correct temperatures, there should be little or no dirt on

the glass. If dirt does settle during lighting, most will burn o as temperatures increase.For

heavier deposits that will not burn o, use Morsø glass cleaner, applied when the glass is

cold, in accordance with the instructions. Never use abrasive cleaners on the glass surface.

Reasons for dirty glass

- Fuel too wet

- Logs too large or not split

- Combustion temperatures too low

Do not clean the glass while hot

Replace broken glass immediately.

Do not operate your stove if the glass in the door is damaged.

If you need to replace the glass, it should be replaced with the high temperature ceramic

class supplied by Morsø, contact your Morsø dealer.

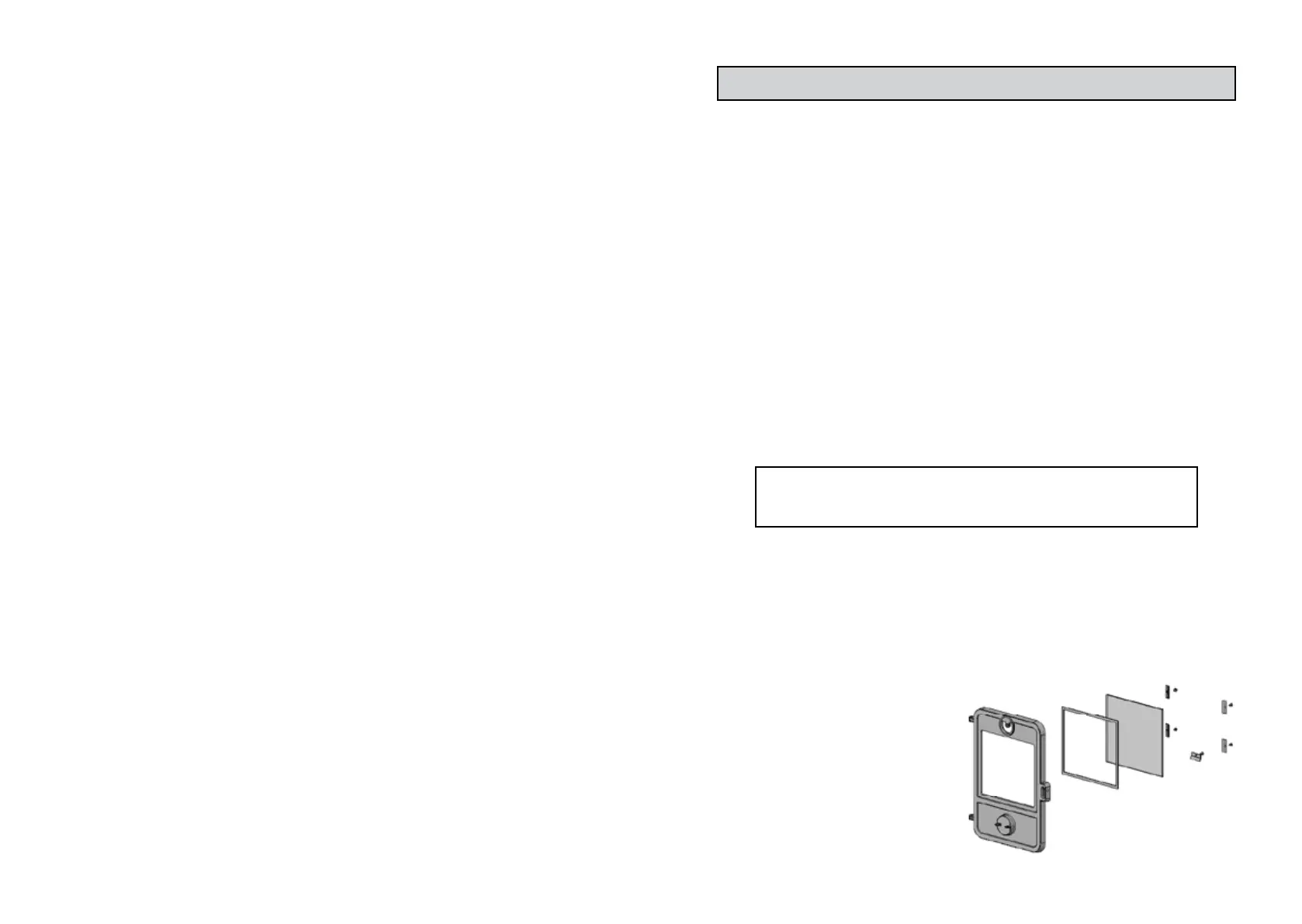

Installing the glass

Never install the glass when the stove is in function.

Ceramic glass replacement

Ceramic glass cannot be recycled because it

has a higher melting point that ordinary glass.

If ceramic glass is mixed with ordinary glass,

the raw material is spoiled, and the

reclaiming process may be halted. Take

care that the ovenproof glass does not end up

among ordinary recycled waste. That

will be a great benet to the environment.

Note: Should be handed in to a

recycling station as ceramic glass.

Loading...

Loading...