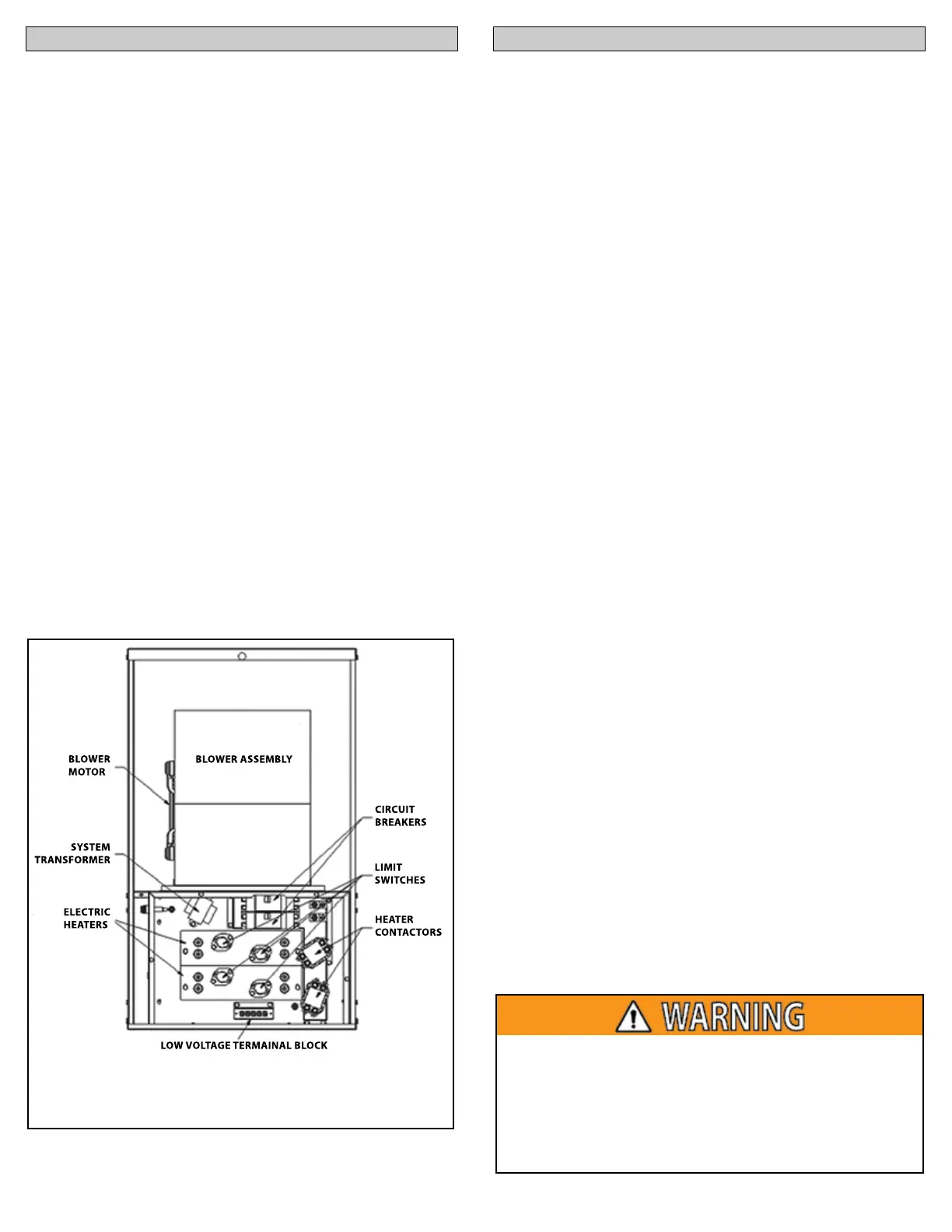

BLOWER

MOTOR

SYSTEM

TRANSFORMER

ELECTRIC

HEATERS

BLOWER ASSEMBLY

CIRCUIT

BREAKERS

LIMIT

SWITCHES

HEATER

CONTACTORS

LOW VOLTAGE TERMAINAL BLOCK

MORTEX PRODUCTS INC. 501 TERMINAL RD FORT WORTH, TX 76106 Page 9

SECTION 3: FURNACE CONTROLS SECTION 4: SEQUENCE OF OPERATION

This section explains how the furnace control operate. Refer to

Figure 8 for component locations.

1. Limit Control(s) – Each electric heating element has a limit

switch directly in front of it to sense the heating element

temperature to prevent overheating. The limit switch opens

if the temperature rises above the set point and interrupts the

24 VAC signal to the heater contactor coil which disconnects

electrical power to the heating element.

2. Heater Contactor(s) –The contactors are controlled by

the thermostat. Upon a call for heat, 24 VAC is sent from the

thermostat “W” terminal to the contactor coil(s) causing the

contactor contacts to close which sends 208/240 VAC to the

electric heating elements. When the call for heat has been

satisfied, the contactor contacts open removing the 208/240

VAC from the heating elements.

3. Circuit Breaker(s) – The circuit breakers are designed as short

circuit protection for the electric heating elements and can also

be used to disconnect the electrical power to the furnace.

NOTE: The circuit breaker(s) are not intended to protect the

wiring from the main control panel (home circuit breaker box)

to the furnace, so the appropriate size breaker(s) or fuse(s) must

be selected (See furnace rating plate) and installed in the main

electrical panel to protect the electrical supply wiring and

furnace.

4. Transformer – The transformer is used to reduce the 208/240

VAC line voltage to 24 VAC which is used by the system control

circuit.

5. 3 Amp Low Voltage Fuse – This fuse is used for over-current

protection of the 24 VAC circuit and transformer.

Figure 8: Component Locations

Continuous Blower

When the thermostat fan switch is in the “ON” position

(continuous indoor fan operation), the circuit between the “R” and

“G” terminals in the thermostat is completed causing 24 VAC to be

sent through the GREEN wire to the “G” terminal on the furnace

low voltage terminal block (LVTB). This energizes the furnace

blower motor and air will be circulated through the ductwork

into the conditioned space. The indoor fan motor will operate

continuously until the thermostat fan switch is switched to the

“AUTO” position.

Intermittent Blower

When the thermostat fan switch is set in the “AUTO” position

(intermittent indoor fan operation), the indoor blower motor

is only energized when there is a call for cooling or heating

operation. Different motor speed taps are typically use for cooling

and heating operating. The indoor fan motor will operate until the

call for cooling or heating is satisfied.

Heating Cycle

When the thermostat is set in the “HEAT” mode and the fan switch

on the thermostat is set in the “AUTO” position, a call for heat

completes the circuit between the “R” and “W” terminals in the

thermostat and 24 VAC is sent from the “W” thermostat terminal

through the WHITE thermostat wire to the W” terminal on the low

voltage terminal block (LVTB).

24 VAC is sent from the LVTB “W” terminal through the limit

controls to the heater contactor coils which closes the contactor

contacts and energizes the heating elements with line voltage.

The blower motor heating speed lead is connected to the “W”

terminal on the LVTB so the blower is energized on the selected

heating speed tap.

The blower will continue to operate until the call for heat has

been satisfied. The electric heater contactor coil is de-energized

which opens the contactor contacts and de-energizes the heating

elements. The 24 VAC signal is also removed from the blower

motor heating speed tap which de-energizes the blower motor.

The furnace is now in standby mode awaiting the next heating

cycle.

The 12 kW, 15 kW and 20 kW models have a BLACK wire that can

be disconnected from the spade terminal on the back of the LVTB

“W” terminal and connected to the wire from the thermostat

“W2” terminal (2nd stage heat) for two-stage heating operation.

A thermostat that has the second stage (W2) heating feature

must be used. The 2nd stage heat cycle is enabled when the room

temperature falls approximately 3 below the thermostat set

point. Once the room temperature is within approximately 1 of

the thermostat set point, the 2nd stage of heat is de-energized

until the thermostat calls for the 2nd stage heat again.

For personal safety be sure to turn the electrical power

For personal safety, turn the electrical power “OFF” to the

furnace at the main electrical panel (circuit breaker box)

before performing service or maintenance on the furnace.

Homeowners/users should never attempt to perform any

servicing or maintenance which requires opening the furnace

control box covers.

Loading...

Loading...