Before any work is performed on the HYDRIVE, remove the

cover and thoroughly clean the unit to remove all traces of

dirt. Do not allow water vapor to enter the hydraulic system

during the cleaning process.

5.1 Maintenance schedule

After the first 10 hours of operation

1. Inspect hydraulic system for hydraulic oil leaks. If leaks

are observed, shut down system immediately and

repair as necessary.

2. Replace the HYDRIVE return filter (19).

3. Inspect all HYDRIVE mounting bolts, fittings and hoses.

Tighten and replace as necessary.

4. Check the HYDRIVE fan speed and relief valve setting.

Adjust as required, following the instructions in this

manual.

Every 3 months

1. Follow the sections 1, 3 and 4 provided in the "After 10

hours of operation" section.

2. When the HYDRIVE hydraulic oil is cold, the oil restric-

tion gauge (20) may read in the red area of the gauge.

After the HYDRIVE warms to operating temperature,

the oil restriction gauge MUST return to the GREEN

level. If the reading fails to return to the GREEN level

the return filter (19) MUST be replaced.

3. Inspect the HYDRIVE radiator (44) and fan (31) for

damage. Carefully clean with air or steam. DO NOT

remove the fan blade balancing clips.

Every 12 months

1. Follow ALL instructions provided in "Every 3 Months"

section.

2. Replace hydraulic oil following the instructions provided

in HYDRAULIC OIL and PRIMING THE HYDRIVE

SYSTEM sections of this manual.

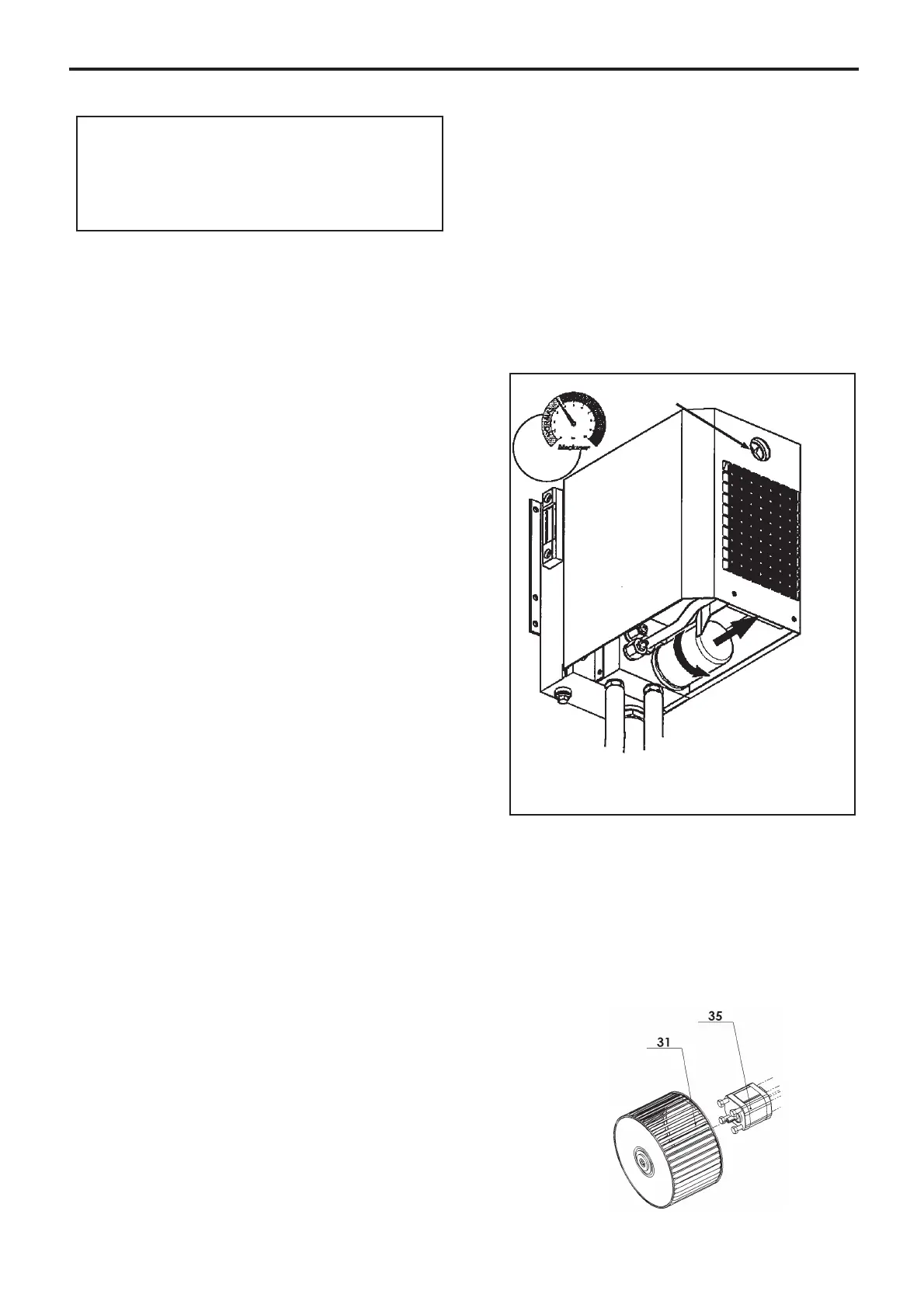

5.2 Return filter replacement

Check the return filter (19) at least every 3 months and

replaced at least every 12 months (see Figure 10).

1. Remove filter by turning it counter-clockwise. If neces-

sary use a filter wrench to remove canister. Properly

dispose of the old filter element.

2. Install new filter element (19). DO NOT overtighten filter

canister.

3. Refill the HYDRIVE resevoir following the instructions

in the HYDRAULIC OIL and PRIMING THE HYDRIVE

sections of this manual.

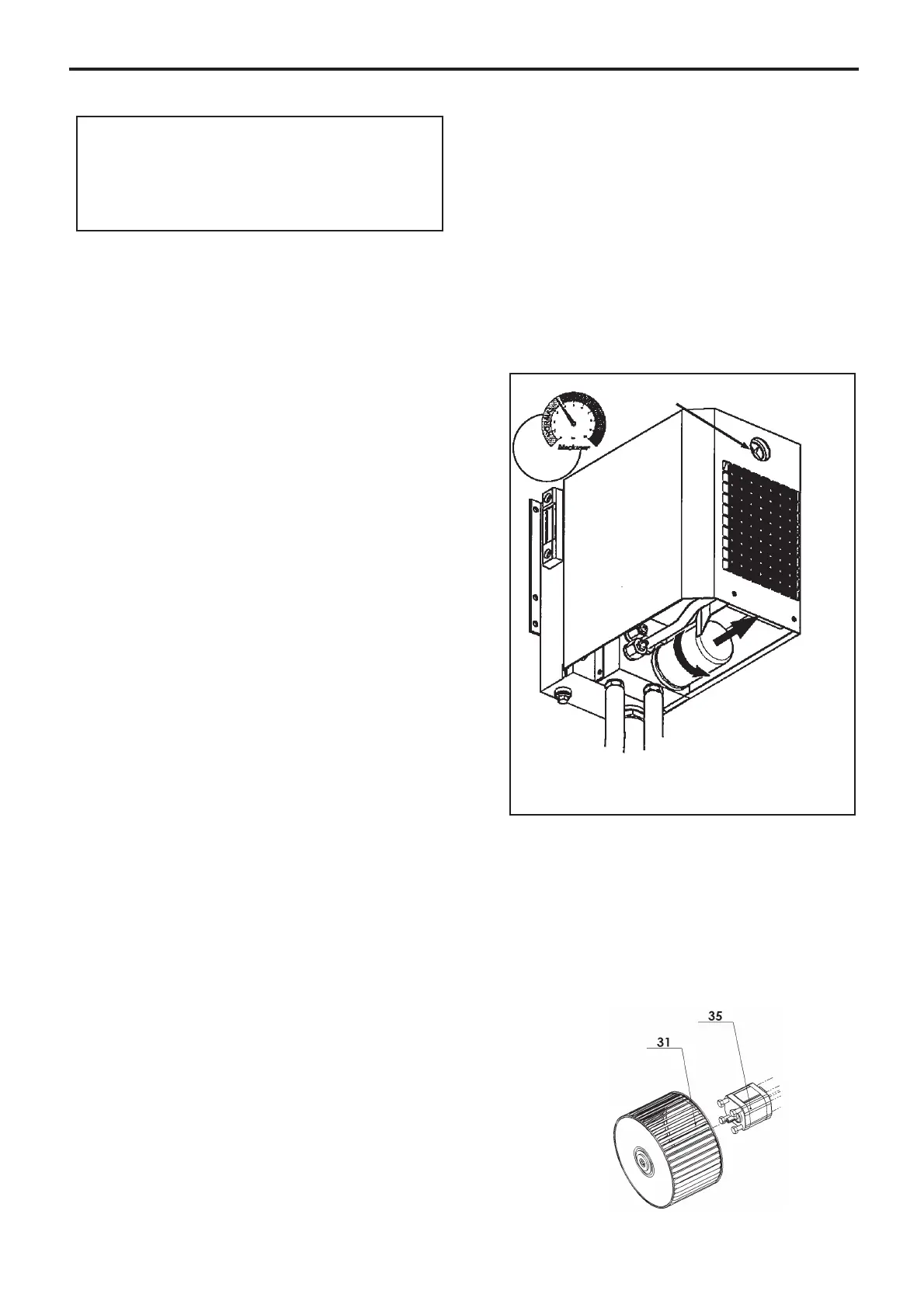

5.3 Fan replacement

The new fan (31) must be fitted on the hydraulic shaft

(35) without forcing :

• Remove any burrs.

• Apply some grease.

• After tightening, check that it rotates perfectly round

and doesn’t touch the structure.

Figure 10

Return filter

Filter gauge

Remove the HYDRIVE return filter

by turning it counterclockwise

NOTICE

HYDRIVE SERVICE SHALL BE PERFORMED BY

QUALIFIED TECHNICIANS ONLY. SERVICE SHALL

CONFORM TO ALL APPLICABLE LOCAL AND

NATIONAL REGULATIONS AND SAFETY STANDARDS.

13/16

NT 206-A00 10.11 Hydrive e

5. MAINTENANCE

Loading...

Loading...