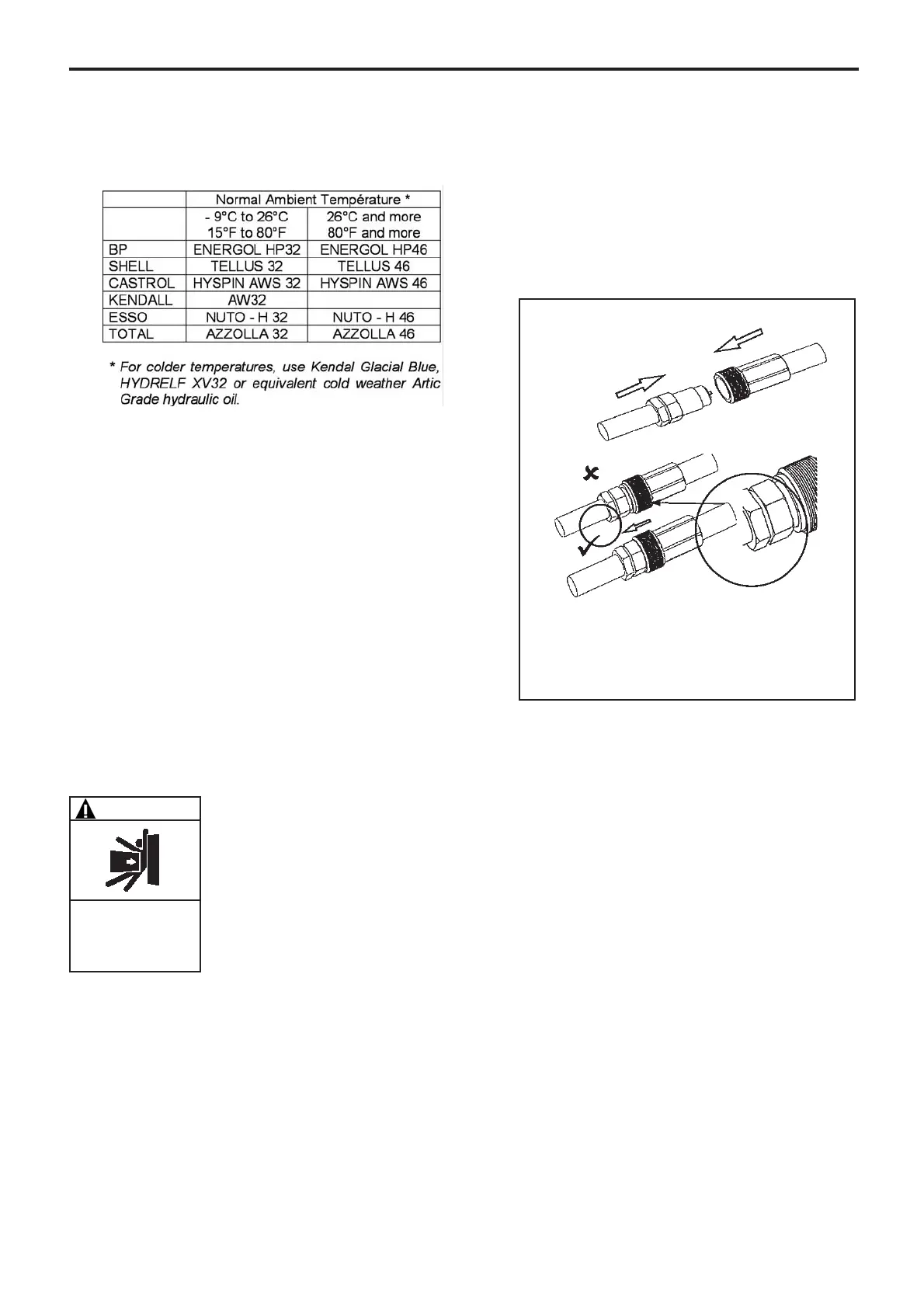

3.3 Hydraulic oil

The System must be filled with one of the following anti-

foaming hydraulic oils, or an equivalent oil :

* Flush all hoses, fittings and the HYDRIVE tank with

hydraulic oil prior to filling the HYDRIVE tank with

hydraulic oil, using the following procedure :

1. Fill the HYDRIVE oil reservoir with suitable hydraulic oil

(see examples above).

2. Disconnect HYDRIVE return hose at the HYDRIVE control

valve block and provide a suitable container to collect

waste hydraulic oil. Properly dispose of waste hydraulic oil.

3. Thoroughly flush the entire system, refilling the HYDRI-

VE reservoir as necessary, until free of all contamina-

tion.

4. Reconnect the HYDRIVE return hose.

NOTICE

DO NOT ALLOW DEBRIS TO ENTER THE HYDRAU-

LIC SYSTEM DURING INSTALLATION OR SERIOUS

DAMAGE TO SYSTEM COMPONENTS MAY OCCUR.

3.4 Priming the system

BEFORE Engaging the PTO follow these steps :

1. Fill the tank with the recommended hydraulic oil, until

the oil reaches the black mark in the sight glass 6.

2. If the HYDRIVE is equipped with a selector valve, move

the valve to the "NEUTRAL" (Center or Off) Position.

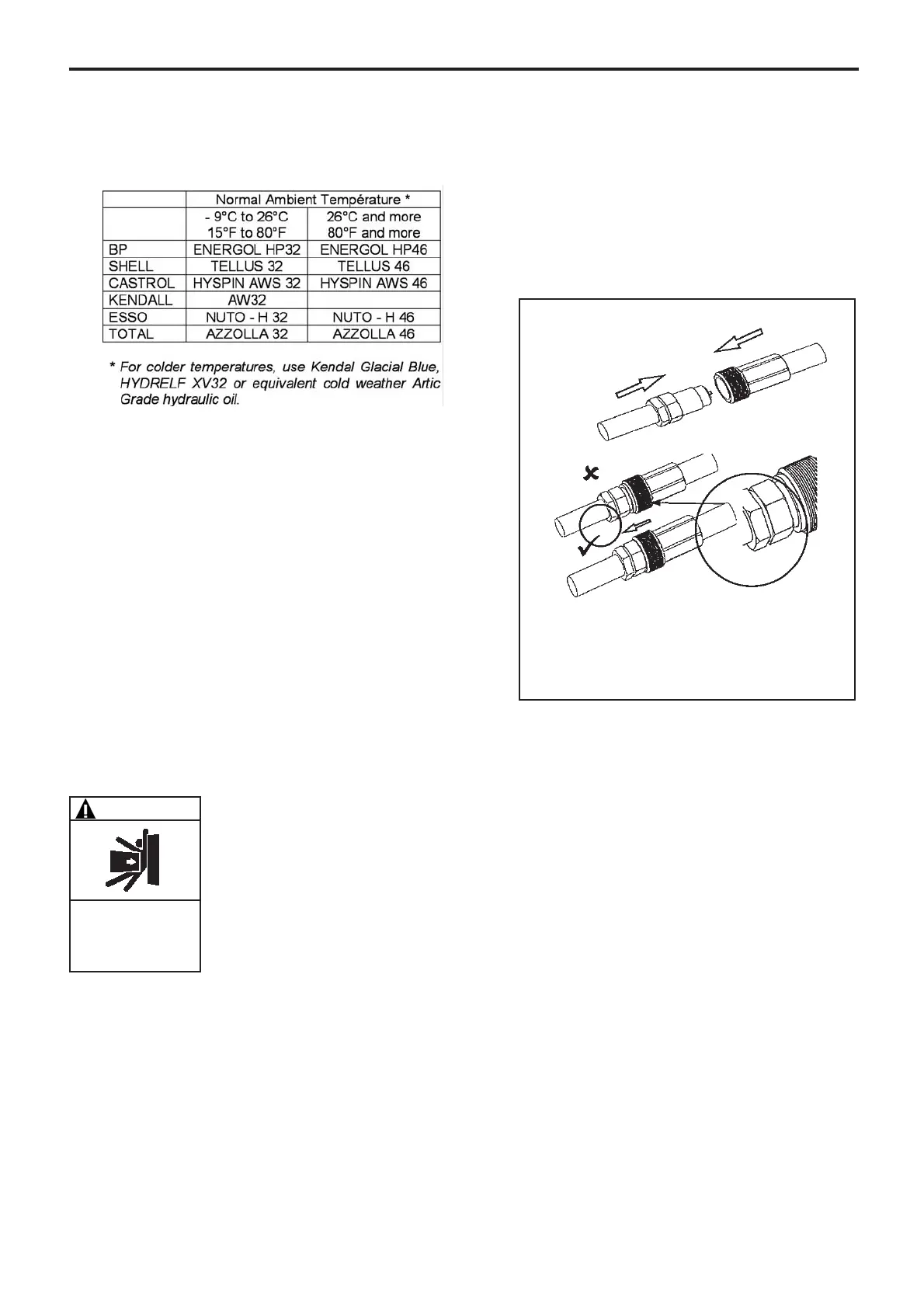

3. Non-spill (dry-break) couplings must be fully

connected. Failure to do so can damage the hydraulic

motor seals.

4. Have a container of suitable hydraulic oil available to

refill the HYDRIVE reservoir as necessary. DO NOT

OVERFILL.

NOTE

Do not fill the HYDRIVE reservoir while the hydraulic

system is running. The level drops during operation

and returns to the full level when not in operation.

5. Make sure the driven cargo pump (or compressor) is

vented and cannot develop pressure.

NOTICE

THE FOLLOWING SYSTEM PRIMING INSTRUCTIONS

MUST BE FOLLOWED TO AVOID ENTRAPPING AIR.

1. Depress the clutch and engage the PTO. Release the

clutch slowly. After approximately 2 seconds depress

the clutch and disengage the PTO.

2. To insure that all system components, hoses and fittings

are completely filled with hydraulic oil, crack the HYDRI-

VE return connection at the HYDRIVE control valve

block (16a or b) allowing any trapped air to escape.

3. During the priming procedure, insure that the hydraulic

oil does not drop below the RED mark on the HYDRI-

VE sight glass (6).

4. Operate any system selector valves and directional

control valves to insure that all hoses and fittings are

free of air.

5. Repeat steps 1 through 4 until system is fully primed.

6. Secure the HYDRIVE control valve block return

connection.

Badly connected return line couplings will damage the hydraulic

motor seals. Ensure the outer sleeve is fully seated in the direction

shown.

Figure 7

Coupling connection

Ensure both halves of the couplings are clean.

WARNING

Hazardous machinery

can cause severe

personal injury

or property damage.

SET THE VEHICLE EMERGENCY BRAKE

BEFORE ENGAGING THE PTO.

9/16

NT 206-A00 10.11 Hydrive e

3. INSTALLATION (continued)

Loading...

Loading...