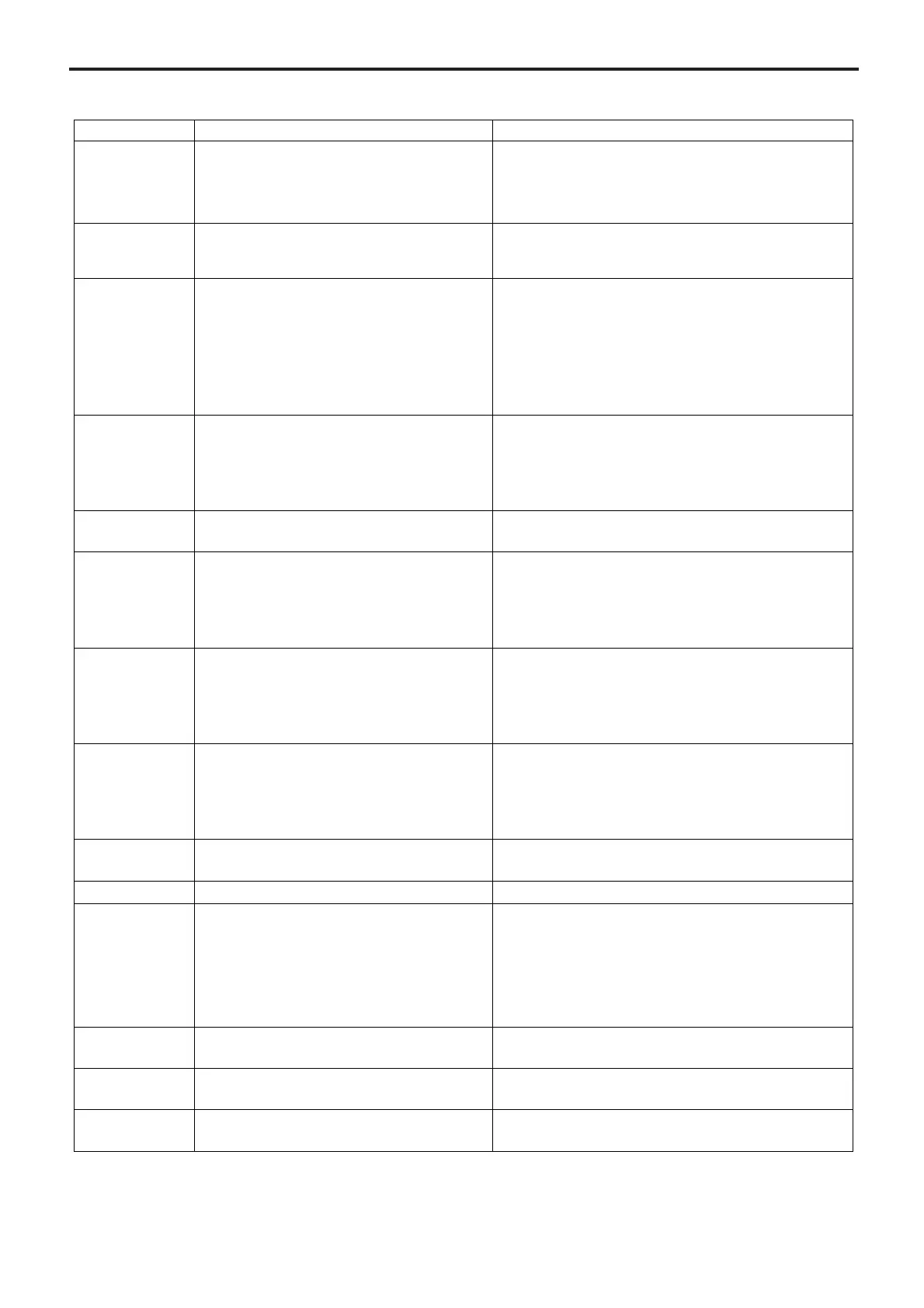

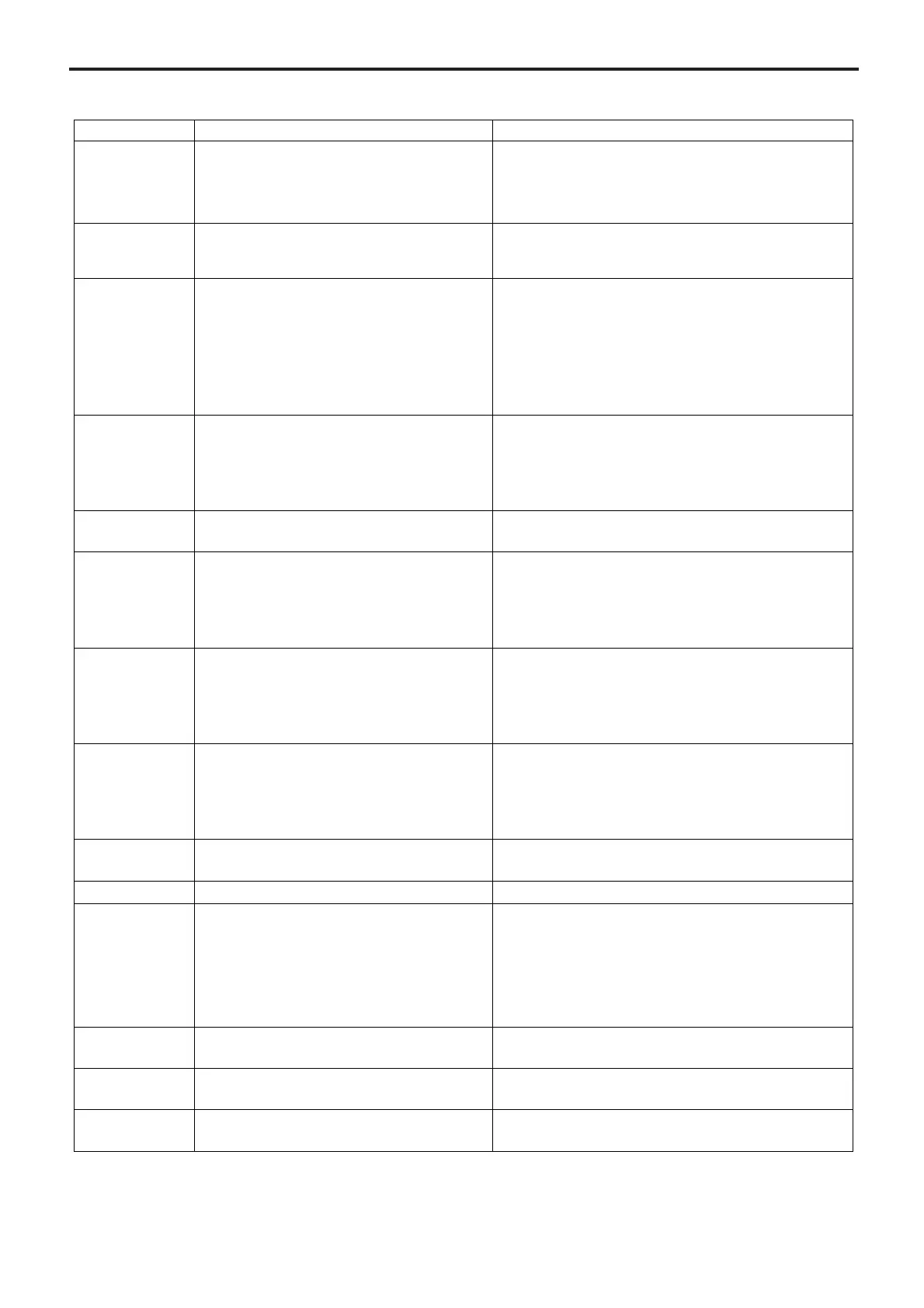

PROBLEM CAUSE CORRECTIVE ACTION

Aeration of the oil

(Oil goes milky)

Insufficient oil getting to the pump.

Air entering the system.

Water entering the system.

See “Cavitation”.

See “Air Entering the System”.

Tighten up all hose connections. Inspect suction pipe for splits.

Replace as required.

Air entering the

system

Low oil level in the tank.

Leaks in suction hose or fittings.

Fill reservoir and re-prime.

Tighten up all hose connections. Inspect suction pipe for splits.

Replace as required.

Cavitation

Suction line to small.

Suction line to long.

Pump is higher than tank.

Suction line has too many restrictions or elbows.

Pump speed is too high.

Use large bore pipe.

Move Hydrive closer to pump.

Re-position Hydrive to ensure there is a positive head pressure at

the pump inlet.

Re-route pipe, and keep number of fittings to a minimum.

Reduce pump speed or select smaller displacement pump.

Distorted / Cracked

tank

Tank under strain from piping.

Mounting surface is not flat.

Tank damaged by mishandling.

Vibration.

Install bulkhead fittings.

Use shims (if necessary), to ensure a flat mounting surface.

Do not step on Hydrive or use to carry extra weight.

See “Vibration”.

High/excessive

circuit pressure

Incorrect hydraulic pump selection.

Driven unit requires higher torque.

Re-check hydraulic calculations.

Check driven unit for seizure or blocked lines.

High/excessive oil

temperature

Insufficient fan speed.

Radiator blocked.

Relief valve opening.

Cold start bypass opened.

Check fan speed. Adjust if required.

Clean radiator.

See “Relief valve problems.

Clean cold start bypass.

Motor seals

damaged or

leaking

Seals worn.

Drain line not connected.

Excessive return line pressure.

High oil temperature.

Repair or replace.

Install case drain and replace motor seals.

See “Return line pressure too high”.

See “Excessive oil temperature”.

Motor not turning

at correct speed

Relief valve opening.

Pump or motor damaged.

Driven unit seized or blocked.

System design.

See “Relief valve problems”.

Overhaul unit.

See manual for driven unit.

Re-check hydraulic calculations.

Pump leaks

Seals worn.

Excessive circuit pressure

Repair or replace.

See “Excessive circuit pressure.

Radiator burst Return pressure to high See “Return pressure too high”.

Return pressure

too high

Return line too small.

Return line too long.

Excessive flow.

Blocked return.

Improperly installed quick release couplings.

Increase pipe size.

Reposition Hydrive.

Reduce speed of driven unit.

Replace return filter.

Ensure couplings are properly installed.

Relief valve

problems

Continuously opening.

Sticking or un-settable relief valve.

Reset the valve 10% above circuit pressure.

Replace with new relief valve.

Vibration –

Hydraulic

Relief valve opening intermittently.

Aeration of the oil.

See “relief valve problems”.

See “Aeration of oil”.

Vibration - Véhicle

Normal vibration from vehicle.

Whole vehicle vibrates badly.

Use anti vibration mounts to isolate Hydrive.

Ensure engine is not mis-firing.

14/16

NT 206-A00 10.11 Hydrive e

6. TROUBLESHOOTING

Loading...

Loading...