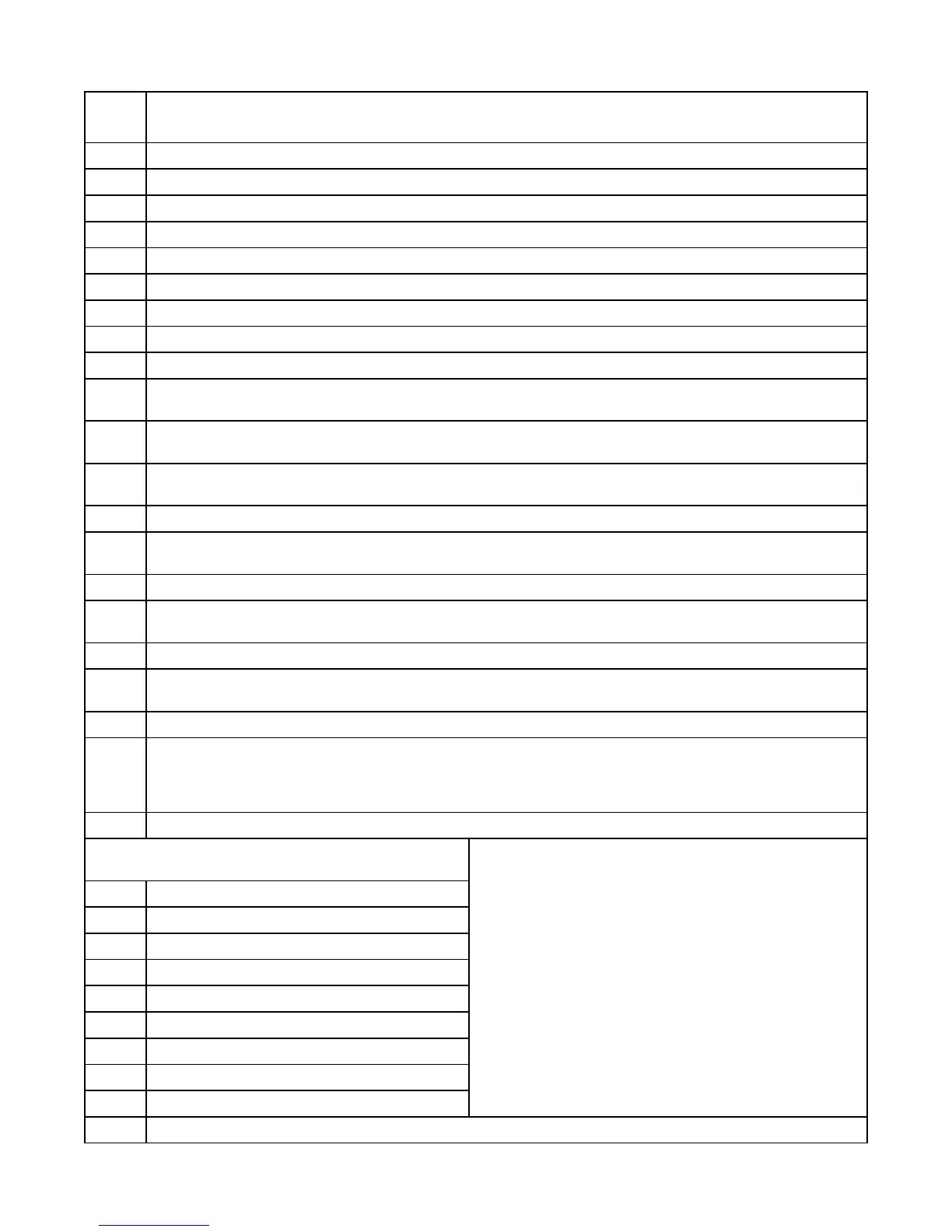

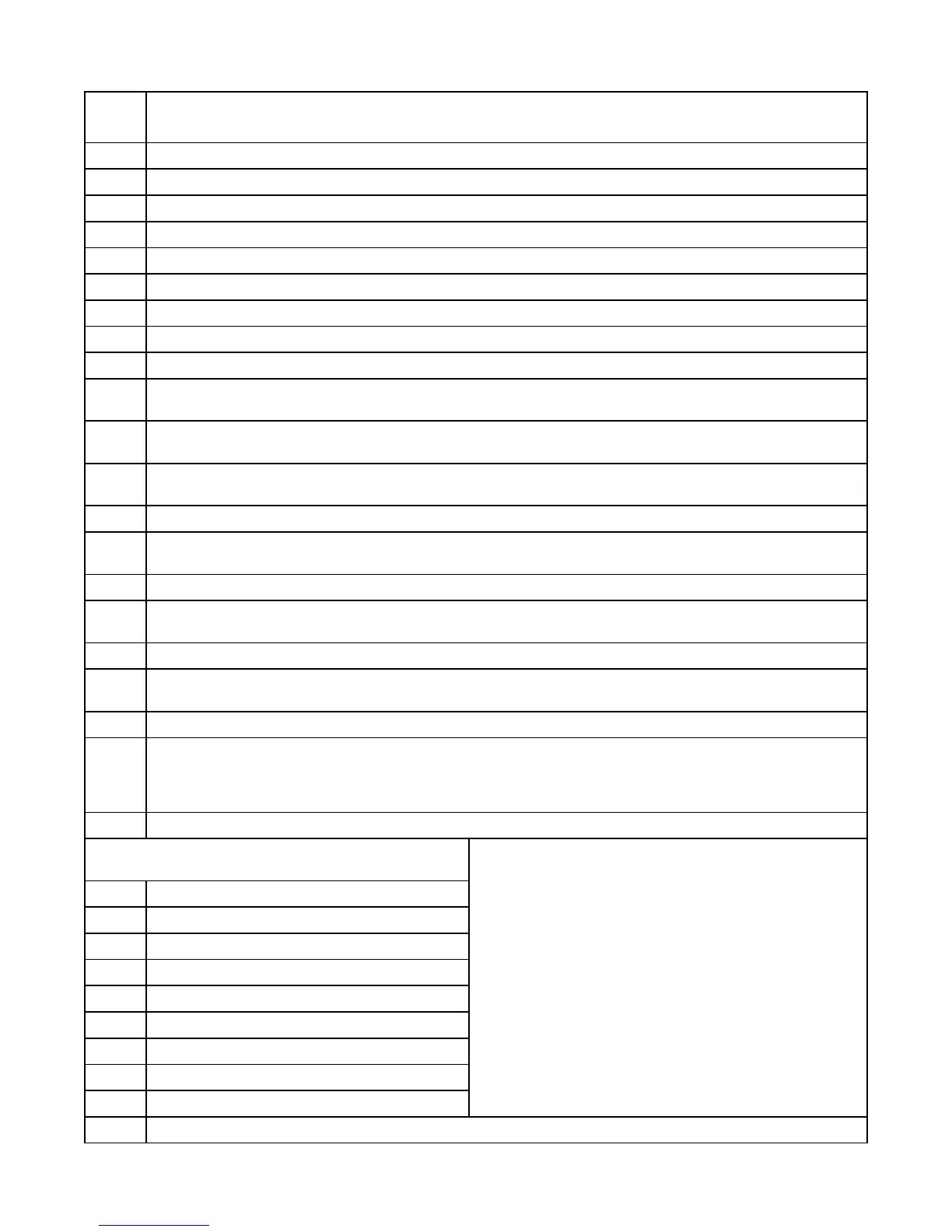

18

Fault

Code

Description of Condition

0 Normal

1 Communication Fault - Overrun Error reading incoming message.

2 Communication Fault - Time out error reading incoming message.

3 Communication Fault - Time out error responding to message.

4 Communication Fault - Incoming message failed Checksum Test.

5 Communication Fault - Invalid Modbus Function Code.

6 Communication Fault - Trying to preset more than 35 registers using Function Code No. 16.

7 Communication Fault - Trying to force to more than 100 Coils using Function Code No. 15.

8 Parameter Setup Fault - More than one Discrete Input is assigned to the same Function.

9

Parameter Setup Fault - Pump On & Pump Off parameters are set too close together. (They must be at least

0.2 feet apart with P.36 = 1, or 2 feet apart with P.36 = 0, or 0.02 feet apart with P.36 = 2.)

10

Parameter Setup Fault - Pump On & Pump Off parameters are upside down. (Pump Off Level must be lower

than the Pump On Level, for a pump down application.)

11

VFD Speed Reference Setup Fault - Level at Minimum Speed is set too close to Level at 100% speed. (They

must be at least 0.5 feet apart with P.36 = 1, or 5 feet with P.36 = 0, or 0.05 feet with P.36 = 2.)

12 VFD Speed Reference Setup Fault - Level at Minimum Speed and Level at 100% speed are backwards.

13

Communication Fault - The UART detected a Framing Error reading the incoming message. It did not find Stop

Bit where expected.

14 Communication Fault - Noise Detected on incoming message.

15

Normal Pump Operation Disabled - Discrete Input programmed for Function 31 is closed. Pump Operation will

only be allowed from Float Backup or Level Probe Backup.

16 Pump Operation on Float Backup.

17

Backup Float Switch Out of Sequence.

Note: Fault will clear when normal operation is verified.

18 All Pump Disable - Discrete Input programmed for Function 8 is closed (Typically connected to Phase Monitor).

19

One of the Pump On or Pump Off level control Parameters (or Parameters P.21, P.22, P.42, or P43) is set too

low. One of them is set in the part of the display range that is artificially created by the Level Offset Parameter

F.21. See page 5 for a description of Parameter F.21. All level control Parameters must be set higher than what

is set on Parameter F.21.

20 Level Probe Fault - Test Signal Status Below Normal Range. See Parameter L.11 on page 7.

Notes:

1.

Level Probe Fault Codes 21-29 must be present for at

least 60 seconds for the fault to be latched into memory.

2. To reset the fault, scroll to and view Parameter FLC. Re-

cord the Fault Code, then press the Down push-button

while viewing the Fault Code. Cycling power to the con-

troller will also reset the Fault Code.

3. The analog value associated with each of the Level Probe

Electrodes may be viewed from Parameters L.01 - L.10.

See page 7.

Fault Codes 21 - 29 Level Probe Fault

Electrodes Covered Out of Sequence

21 Electrode 1 Covered before Electrode 2

22 Electrode 2 Covered before Electrode 3

23 Electrode 3 Covered before Electrode 4

24 Electrode 4 Covered before Electrode 5

25 Electrode 5 Covered before Electrode 6

26 Electrode 6 Covered before Electrode 7

27 Electrode 7 Covered before Electrode 8

28 Electrode 8 Covered before Electrode 9

29 Electrode 9 Covered before Electrode 10

30 Pump(s) are Called to Operate by the Level Probe Backup Pump Control.

FAULT CODE TABLE

Loading...

Loading...