The Test Bench MS300 for diagnostics and repair of brake calipers is intended for long lasting

operation under twenty-four-hour schedule. However, it is essential to inspect the equipment

and observe preventive measures described below with recommended intervals for trouble-free

enduring operation. It is recommended to clean the system from metal chip and other

contamination with a soft brush or cloth on nishing the daily operating shift.

Control the electric motor operation while using the test bench. Unusual sounds, excessive

heating, vibration signalize of a failure.

The recommended period for changing the hydraulic uid (DOT4) and the system lter element

(CR091C10R) is one year of operation. Besides, the brake uid condition and the necessity of its

change is assessed visually, according to its view. It should be transparent, homogeneous,

without sediment. The valve 15 (Fig. 1). is intended for drainage of the power uid. Filling and

relling of the test bench hydraulic system is carried out through the test bench drainage block.

The power uid volume in the hydraulic system is measured with the level sensor 14 (Fig. 1).

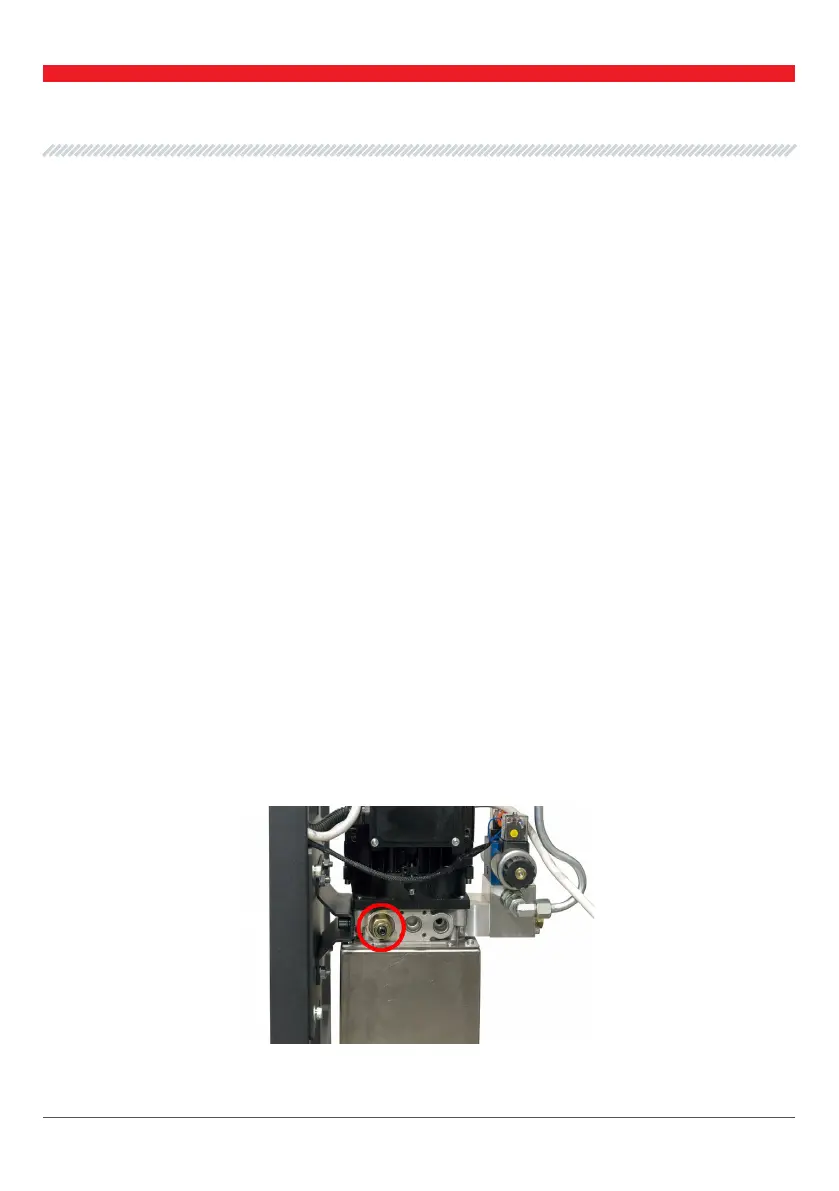

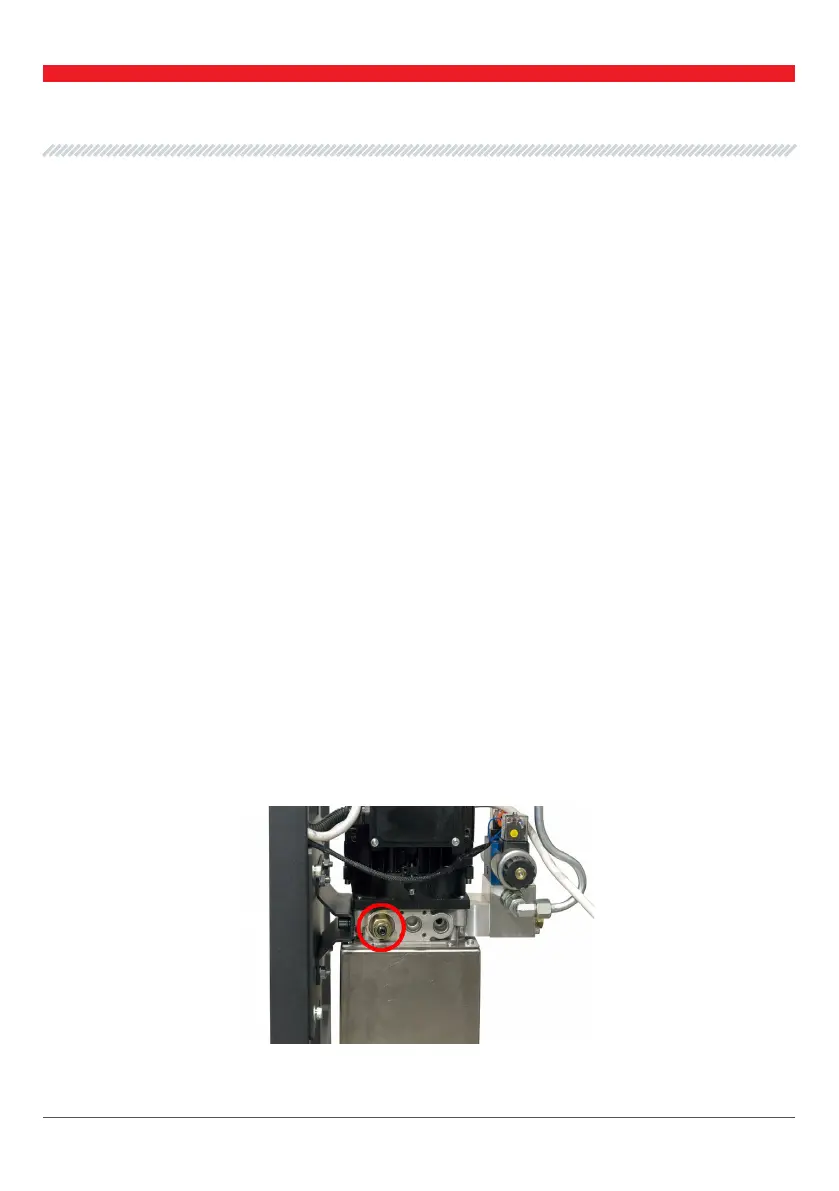

The hydraulic system power pressure adjustment is carried out with the help of the adjustment

valve (hexagon) (Fig. 9).

Fig. 9 – Pressure adjustment valve

6.1 Change of power uid

6.2 Hydraulic system power pressure adjustment

6. MAINTENANCE MS300

14

User Manual - Test bench MSG MS300

English

Loading...

Loading...