Maintenance& Adjustments

6

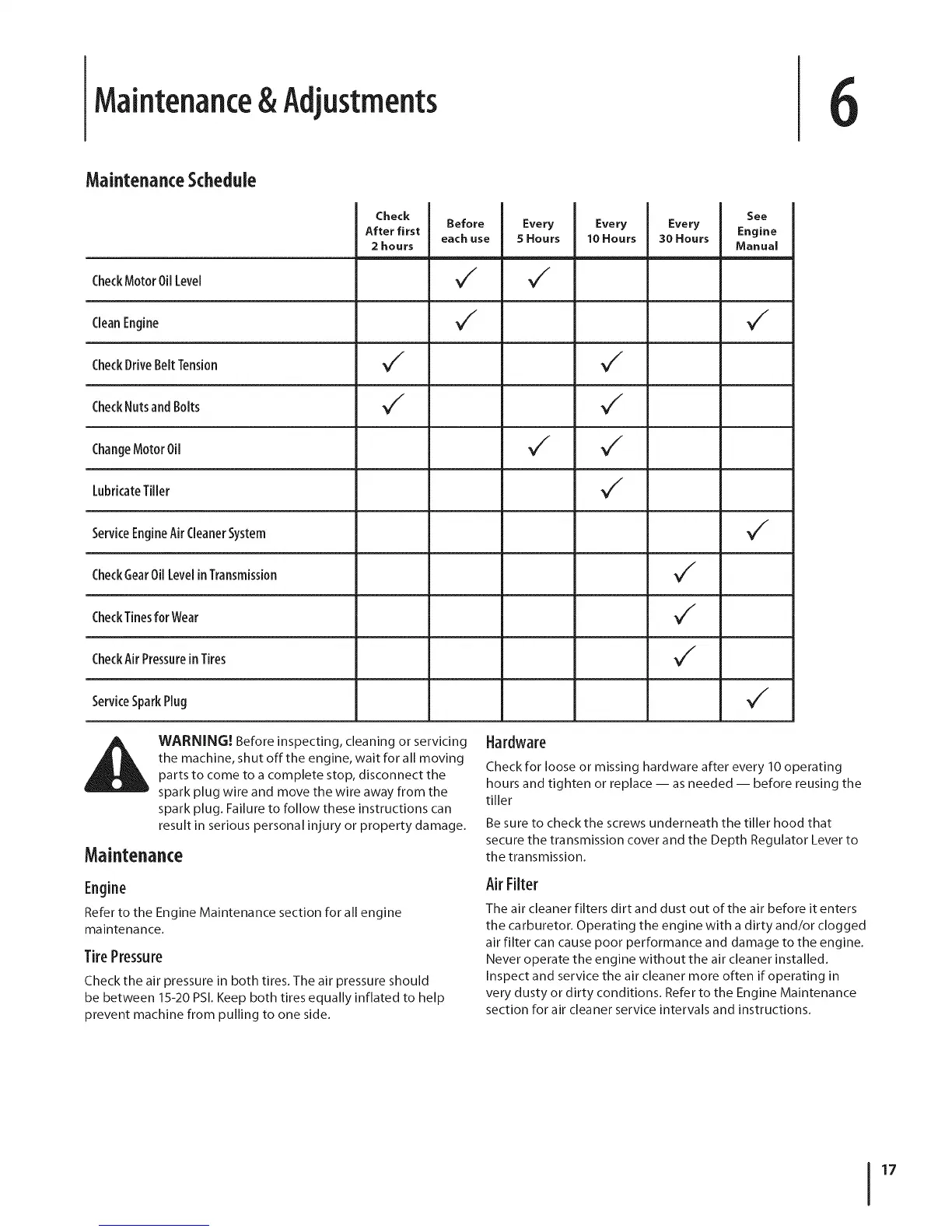

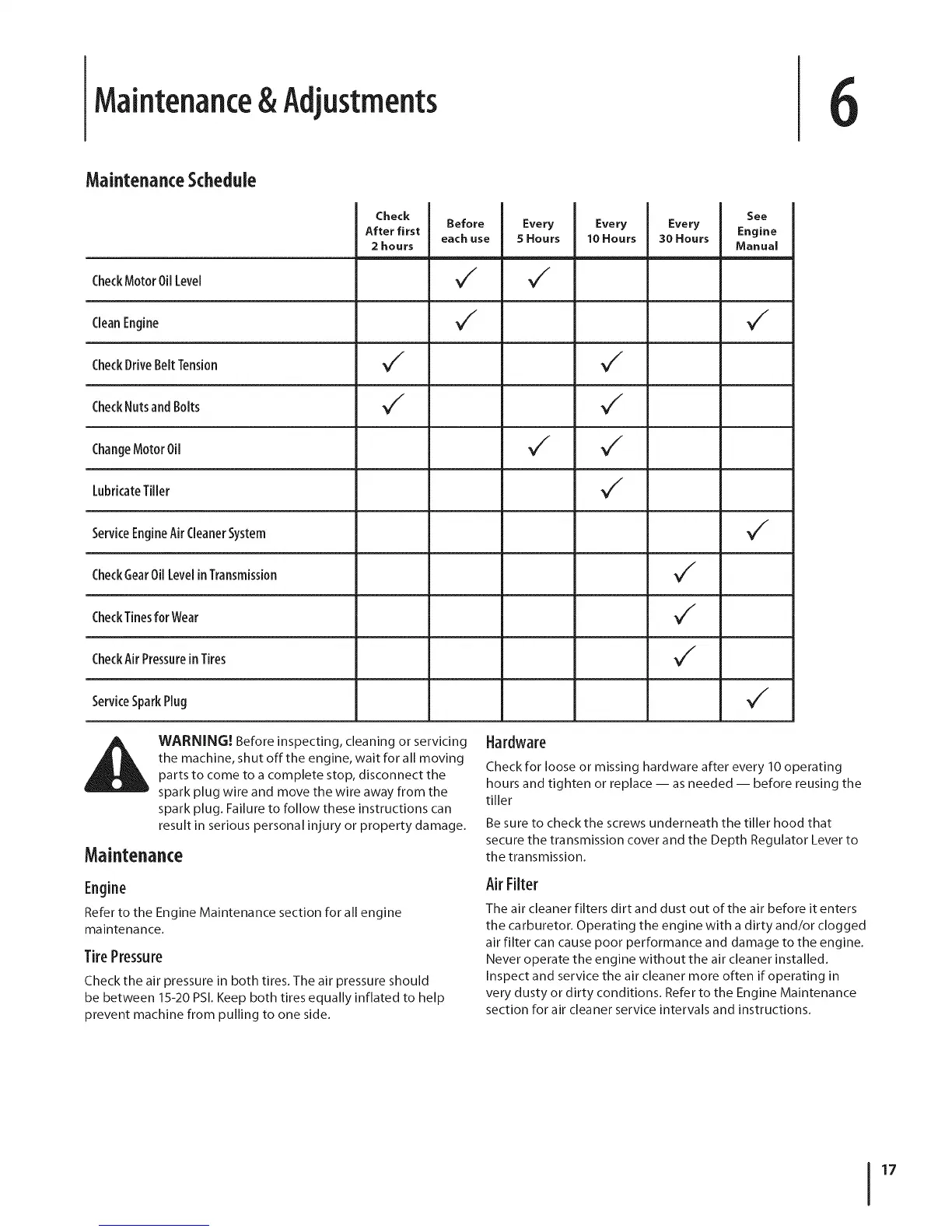

MaintenanceSchedule

Check

After first

2 hours

Every

5 Hours

Every

10 Hours

Every

30 Hours

See

Engine

Manual

CheckMotor OilLevel VII VII

CleanEngine _/ _/

CheckDriveBekTension VII VII

CheckNutsandBolts V / V /

ChangeMotor Oil V / V /

LubricateTiller V /

ServiceEngineAirCleanerSystem _/

CheckGearOilLevelinTransmission V /

CheckTinesfor Wear V f

CheckAir PressureinTires V /

ServiceSparkPlug V /

_ WARNING! Before inspecting, cleaning or servicing Hardware

the machine, shut off the engine, wait for all moving

parts to come to a complete stop, disconnect the

spark plug wire and move the wire away from the

spark plug. Failure to follow these instructions can

result in serious personal injury or property damage.

Maintenance

Engine

Refer to the Engine Maintenance section for all engine

maintenance.

TirePressure

Check the air pressure in both tires. The air pressure should

be between 15-20 PSI. Keep both tires equally inflated to help

prevent machine from pulling to one side.

Check for loose or missing hardware after every 10 operating

hours and tighten or replace -- as needed -- before reusing the

tiller

Be sure to check the screws underneath the tiller hood that

secure the transmission cover and the Depth Regulator Lever to

the transmission.

Air Filter

The air cleaner filters dirt and dust out of the air before it enters

the carburetor. Operating the engine with a dirty and/or clogged

air filter can cause poor performance and damage to the engine.

Never operate the engine without the air cleaner installed.

Inspect and service the air cleaner more often if operating in

very dusty or dirty conditions. Refer to the Engine Maintenance

section for air cleaner service intervals and instructions.

17

Loading...

Loading...