61, 65 and 70 Series Vertical Shaft Engines

98

IMPORTANT: The taper in flywheel and the on the

crankshaft must be clean and dry. The flywheel is

held in place by the friction fit between the flywheel

and the crankshaft, not the key. The key is only to

guide the flywheel to the proper position until it is

torqued down.

7. Install the flywheel nut to a torque of 47 - 52 ft lbs

(64-70 Nm).

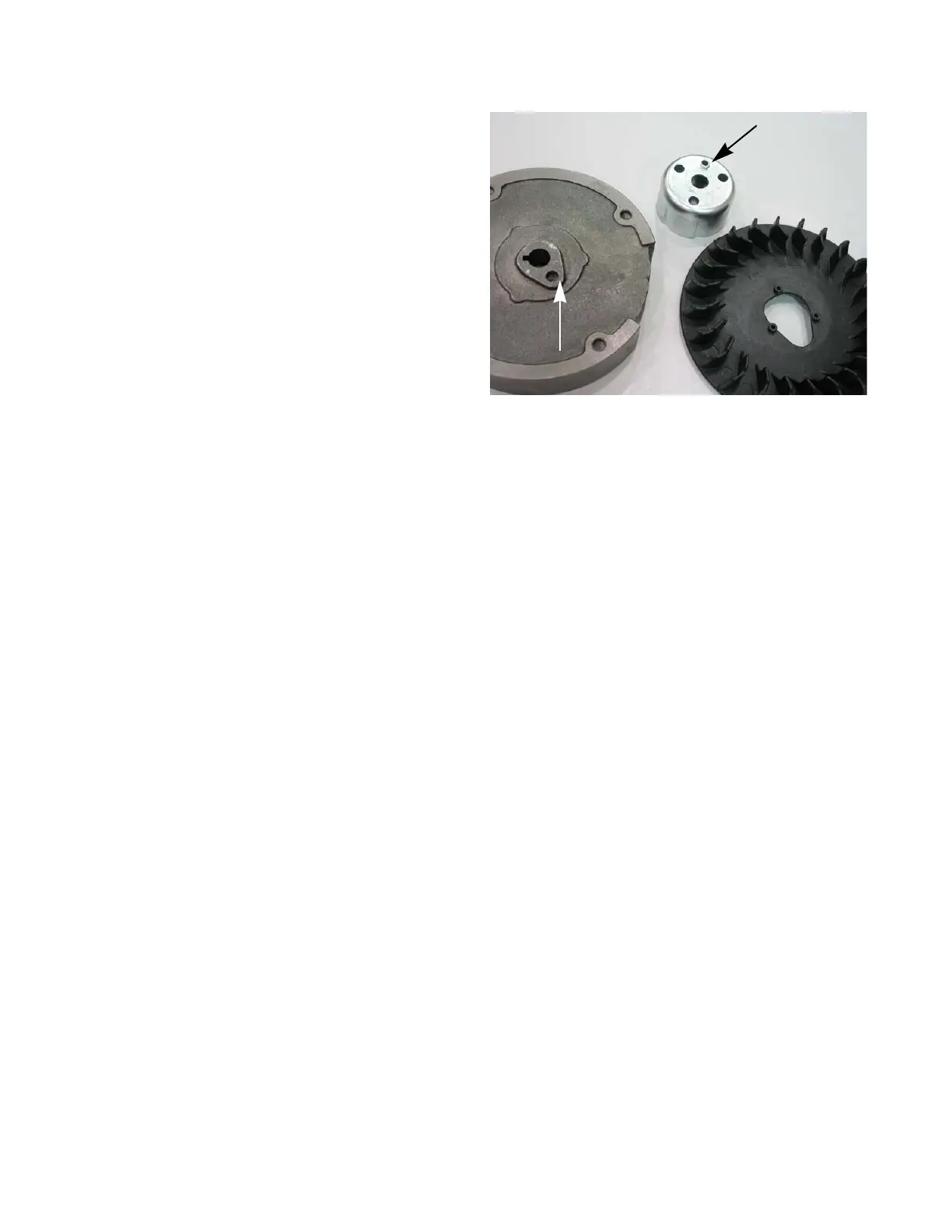

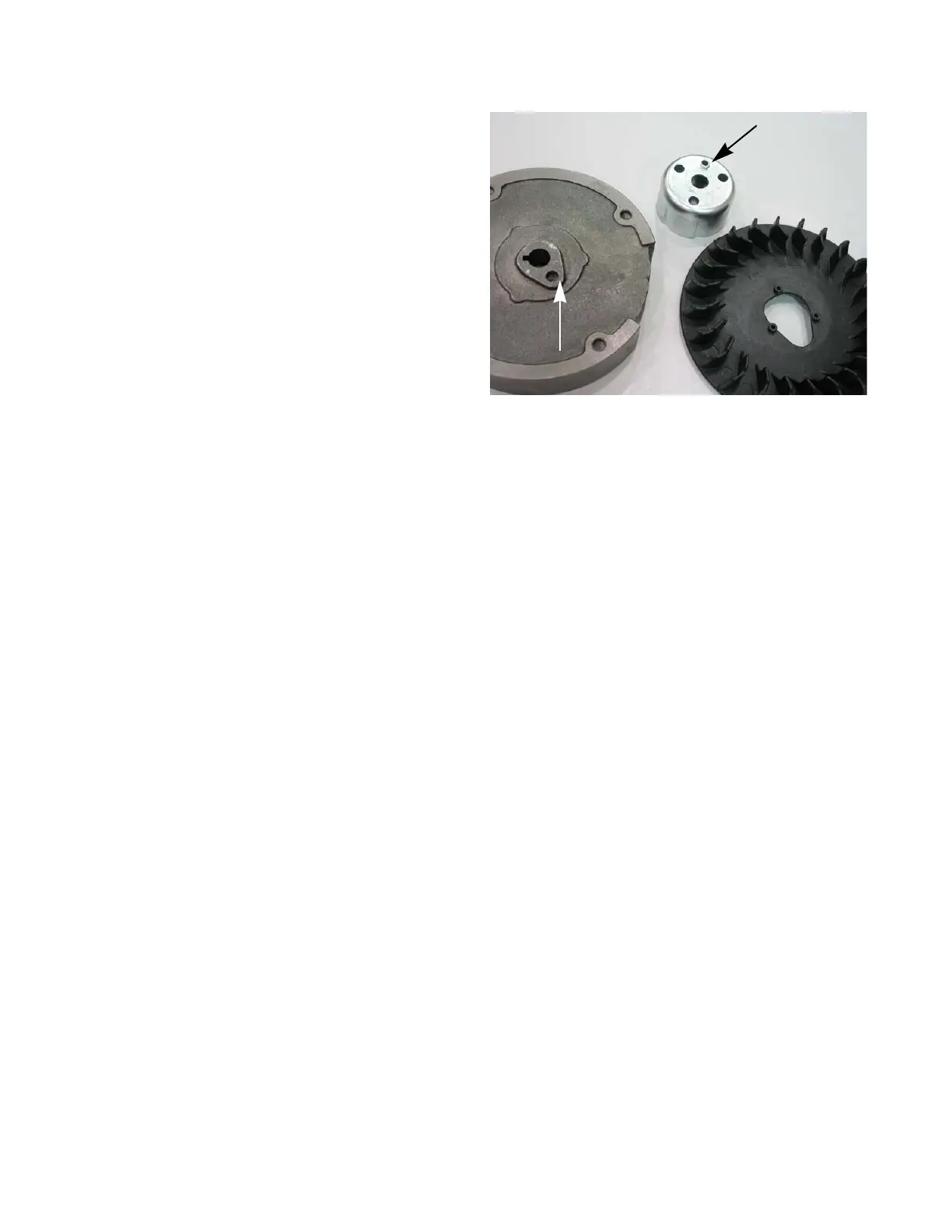

NOTE: If the engine has a cast iron flywheel; install

a starter cup by placing the starter cup on

the flywheel. Allow the protrusion on the bot-

tom of the starter cup to rest inside the dim-

ple in the flywheel with the plastic fan

trapped in between the two. See Figure

6.28.

8. Adjust the air gap by following the steps described in the previous section of this chapter.

9. Reassemble the engine.

10. Test run the engine before returning to service.

Figure 6.28

Starter cup protrusion

Flywheel dimple

Loading...

Loading...