CRANKSHAFT, PISTON AND CONNECTING ROD

71

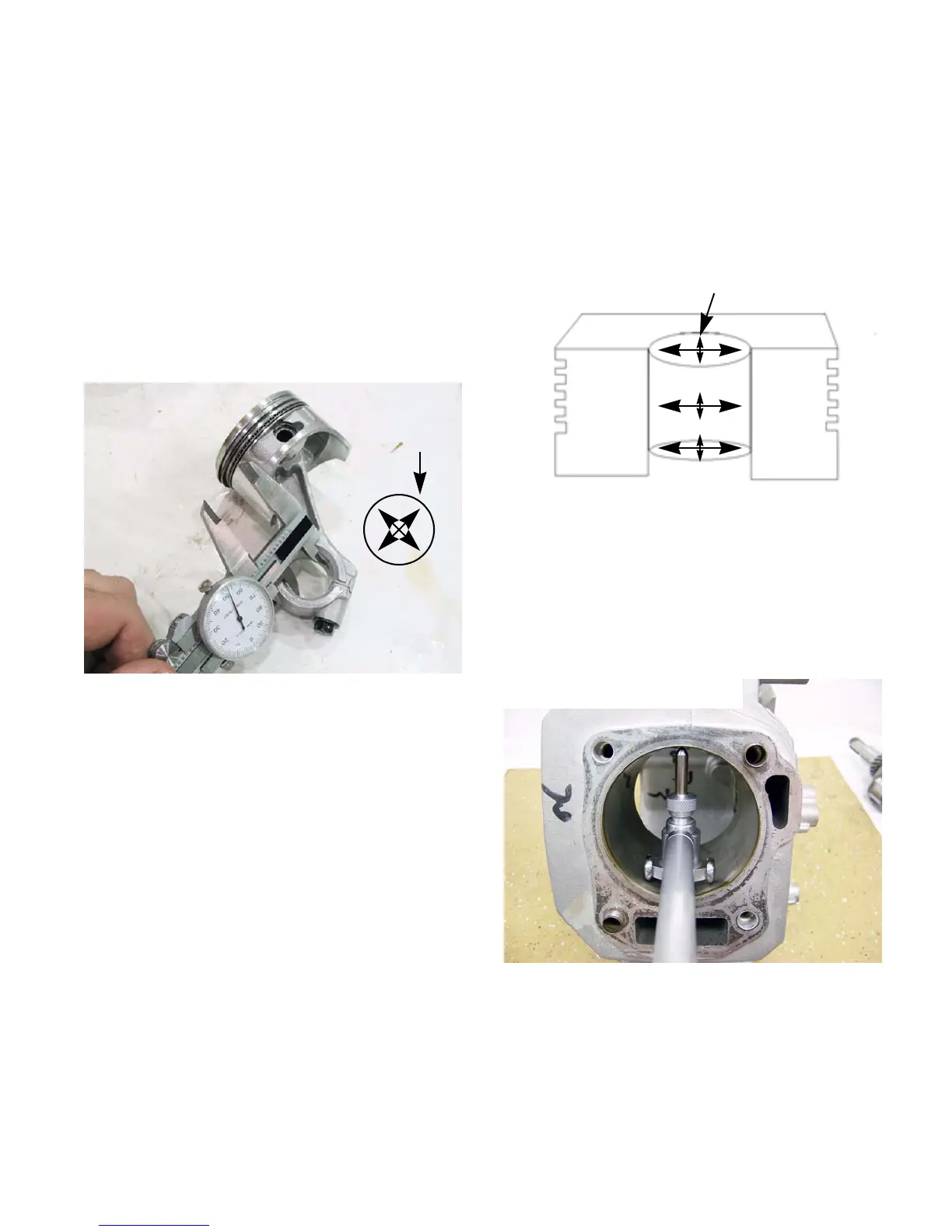

Connecting rod inspection

1. Inspect the connecting rod for cracks or any

signs of damage.

2. Install the rod cap and tighten to a torque of 106

-124 in-lbs (12 - 14Nm).

3. Measure the inside diameter of the connecting

rod and compare the measurements to those

listed in the chart at the end of this chapter.

See

Figure 10.12.

NOTE: Take two measurements 90 degrees

apart. This will check the out of roundness of the

connecting rod.

NOTE: Connecting rods are not available as ser-

vice parts. If the connecting rod is bad, the

engine must be short blocked.

4. Take the crank shaft journal measurement and

subtract it from the connecting rod measurement

to get the connecting rod to journal running

clearance. Compare that number to the one

listed in the chart at the end of this chapter.

NOTE: Plasti-gauge can be used to measure the

connecting rod to journal running clearance, but

it is very technique sensitive and it is not as reli

-

able as the method described above.

Figure 10.12

Measure at

right angles

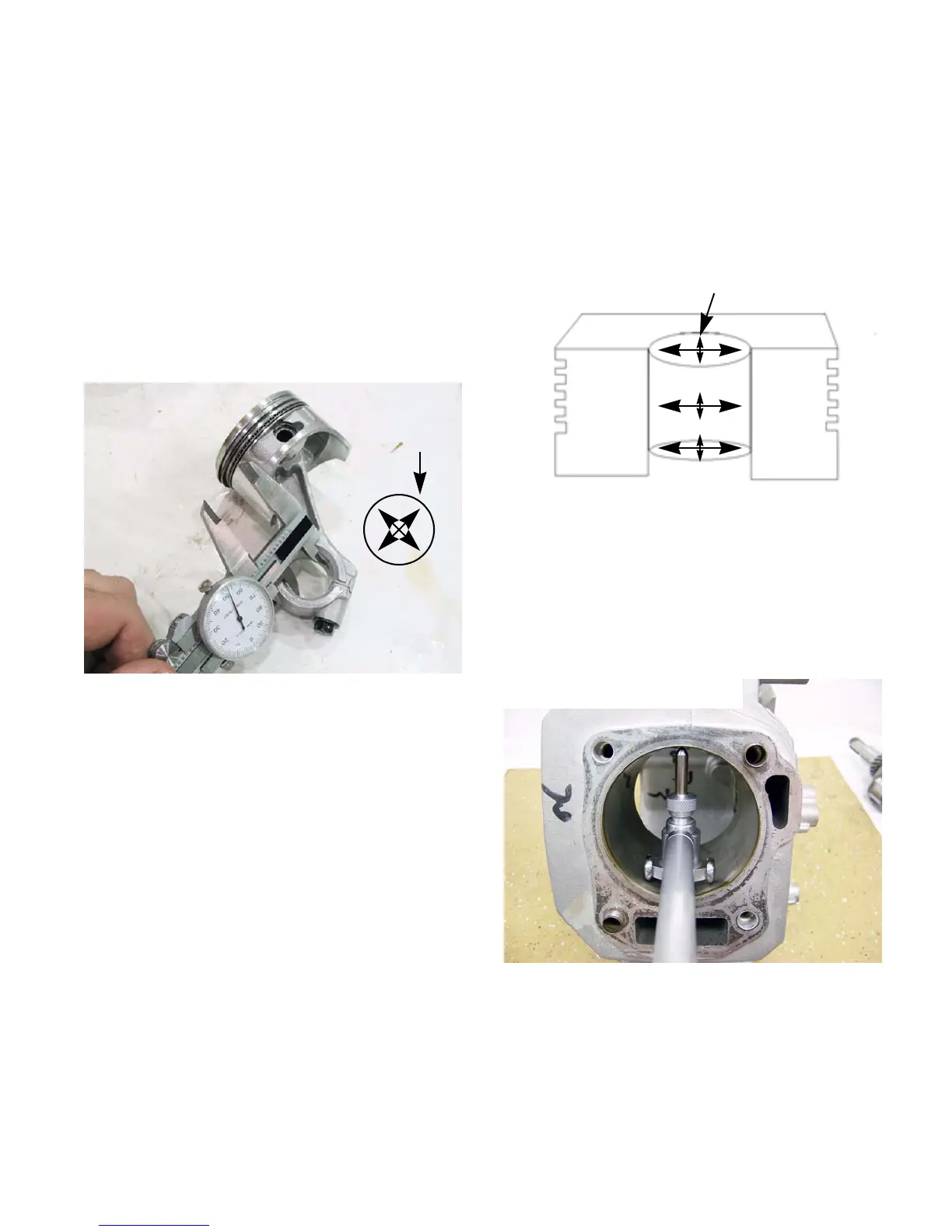

Cylinder inspection

1. Clean and inspect the cylinder, inside and out.

NOTE: If there is any sign of damage, especially

cracked cooling fins, short block the engine.

NOTE: Take two measurements of the cylinder

bore 90 degrees apart at the top, bottom and

middle of the cylinder.

See Figure 10.13.

NOTE: The measurements can be made using

telescoping gauges, inside micrometers or dial

indicating bore gauge.

See Figure 10.14.

Figure 10.13

Measure the cylinder bore

Figure 10.14

Measuring the cylinder bore using

a dial indicating bore gauge

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...