BASIC TROUBLESHOOTING

17

Compression test

To perform a compression test:

NOTE: Compression should be in the range of

40-60 PSI (2.81-4.1 Bar).

• Disconnect the high-tension lead from the spark

plug and ground it well away from the spark plug

hole.

• Remove the spark plug using a 13/16” or 21mm

wrench. A flexible coupling or “wobbly” exten-

sion may help.

• Pull the starter rope several times to purge any

fuel or oil from the combustion chamber.

NOTE: Air compresses readily, liquid does not.

Liquid in the combustion chamber will result in

an artificially high compression reading.

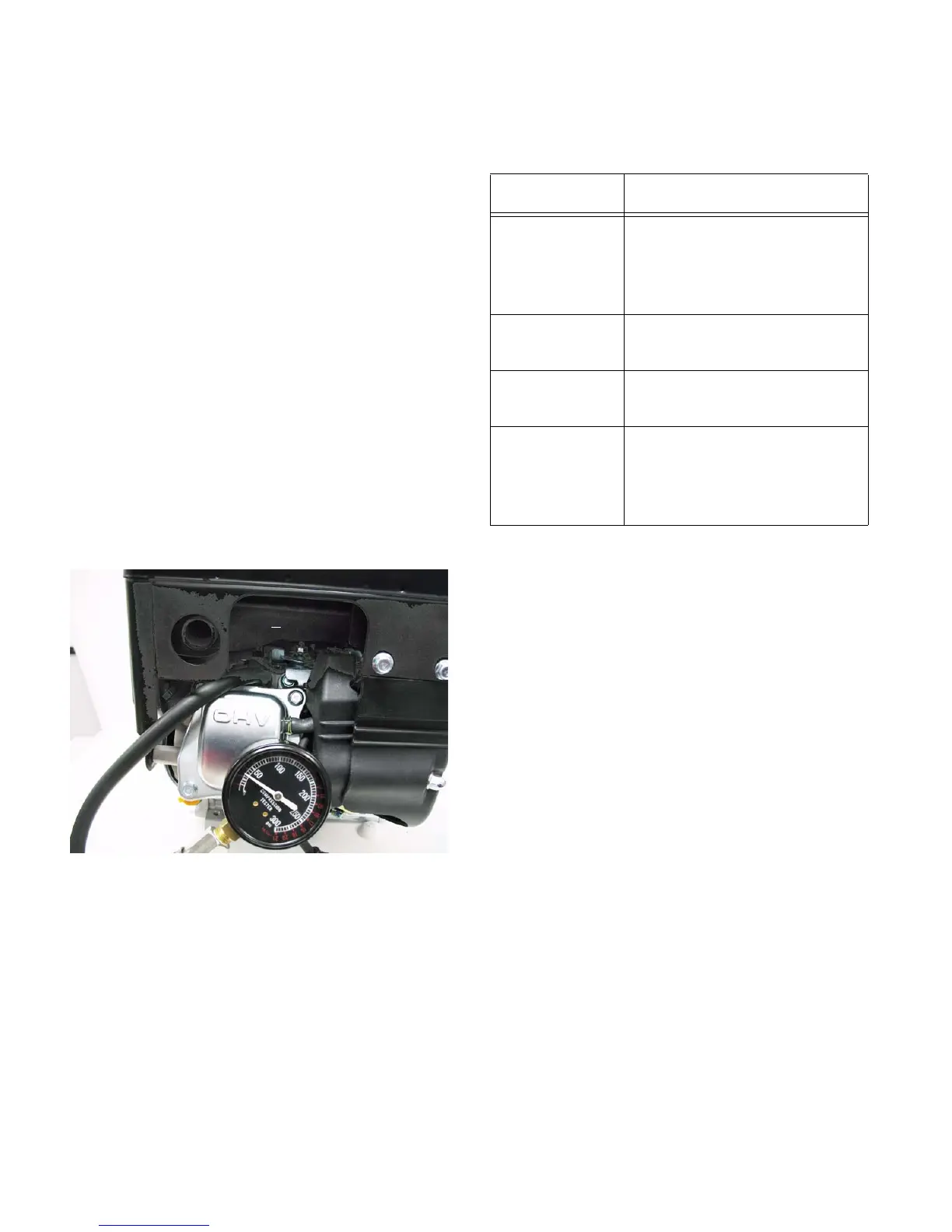

1. Install a compression gauge in the spark plug

hole.

2. Confirm that the gauge is “zeroed”, then pull the

starter rope repeatedly, until the needle on the

gauge stops rising.

See Figure 2.2.

3. Interpreting compression readings.

Figure 2.2

Compression gauge

Reading ~

40 PSI

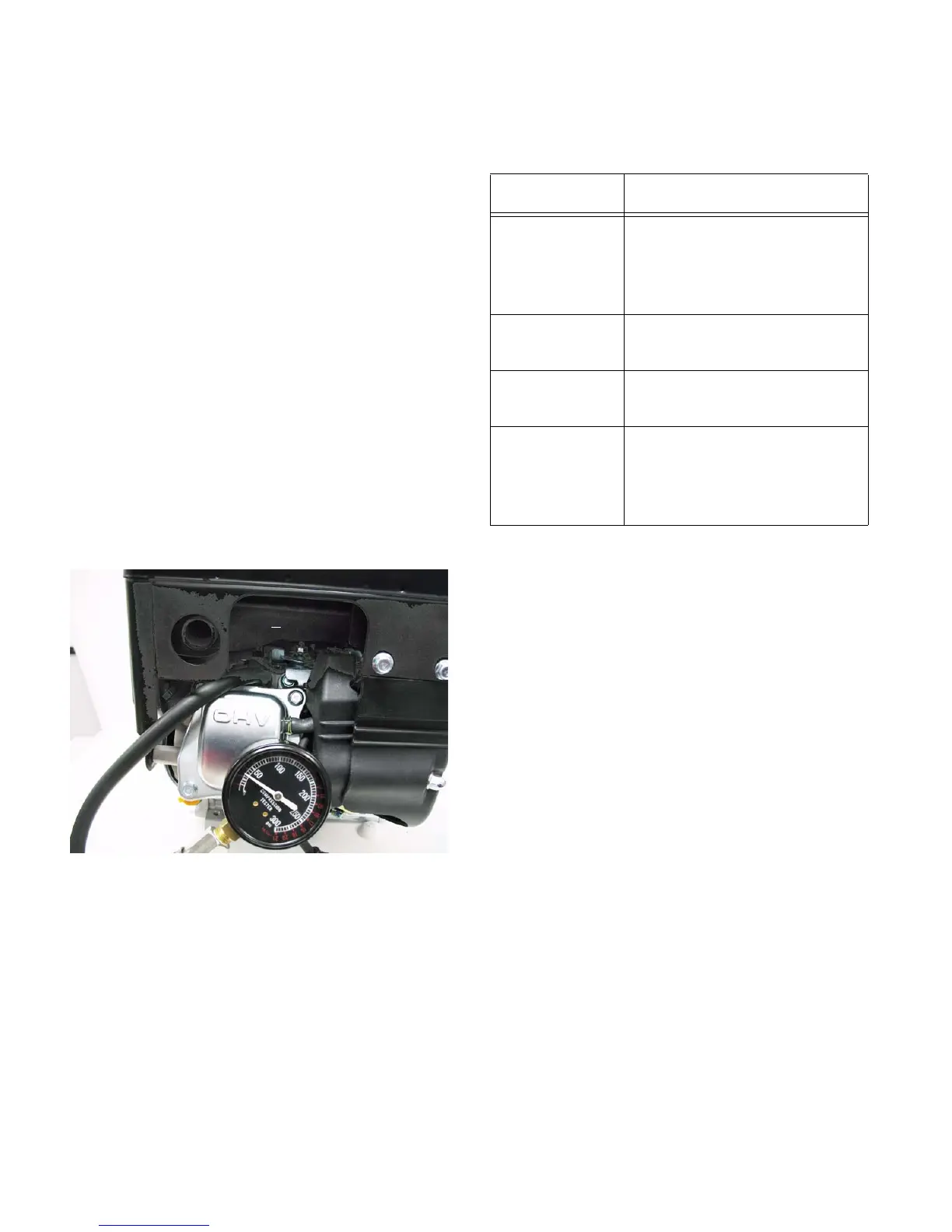

Table 2:

Readings in psi Possible causes

<20

(1.38 Bar)

Most likely a stuck valve or

too tight of a valve lash, pro-

vided the starter rope pulls

with normal effort.

20-35

(1.38-2.4 Bar)

Valve seat damage or piston

ring and/or cylinder wear.

35-95

(2.4-6.5 Bar)

Normal readings

>95

(>6.5 Bar)

Excessive valve lash, a partial

hydraulic lock, a bad cam or a

bad automatic compression

relief.

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...