Temposonics

®

E-Series CANopen

Operation Manual

13

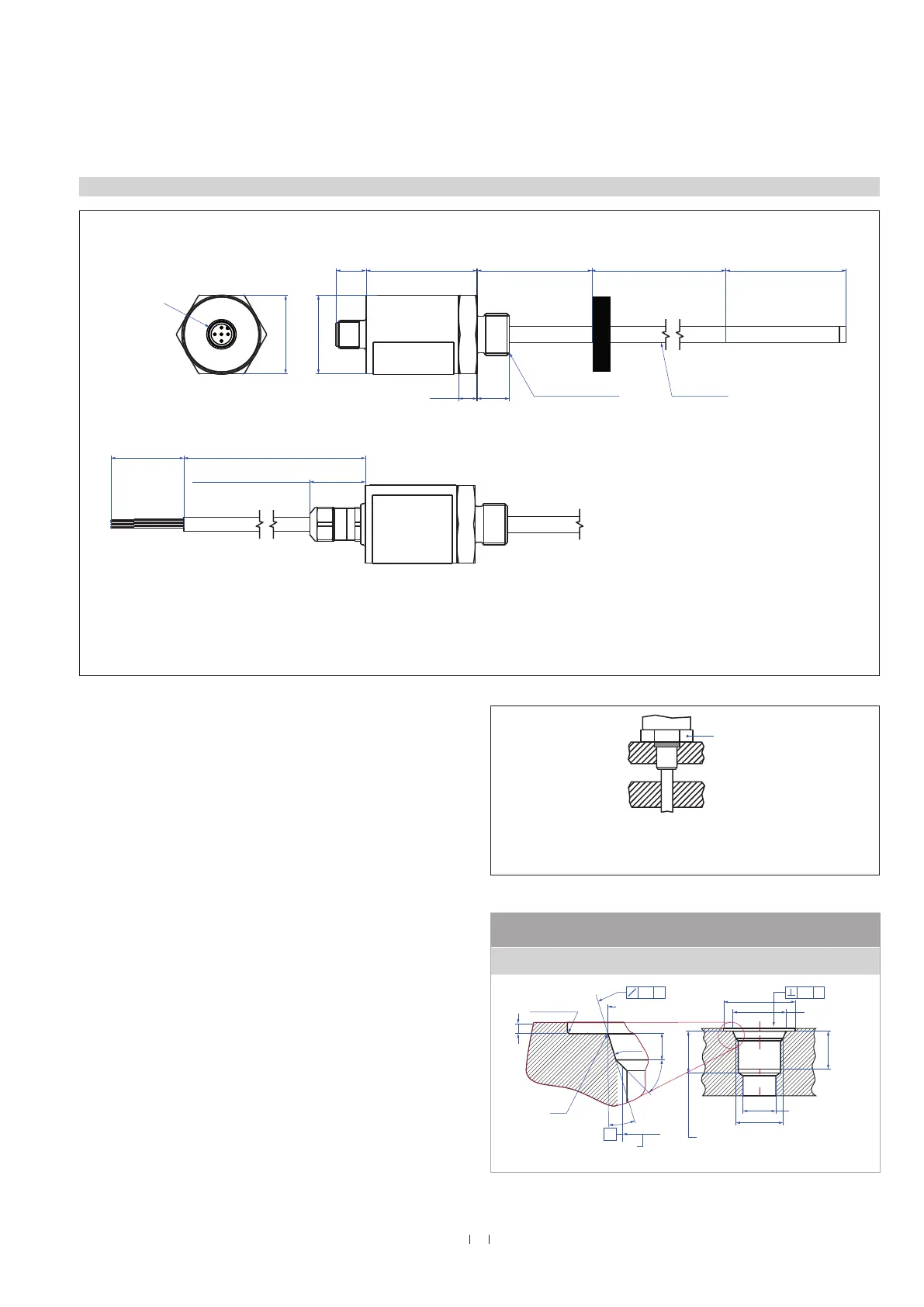

4.4 Styles and installation of E-Series EH

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Unless otherwise stated, apply to the general tolerances according to DIN ISO 2768-m

Fig. 8: Temposonics

®

E-Series EH

Magnet

Ø 34

(Ø 1.34)

AF 34

Sensor electronics housing

48

(1.89)

13

(0.51)

63.5

(2.5)

50…2540

(2…100)

8

(0.31)

Sensor rod

Type: Ø 7 ± 0.10 (Ø 0.28 ± 0.01)

Type: Ø 10 ± 0.13 (Ø 0.39 ± 0.01)

51

(2)

PUR cable: 24.3 (0.96)

Teflon

®

cable: 26 (1.02)

Cable length

60

(2.36)

14

(0.55)

Threaded flange

Type: M18×1.5−6g

or

Type: ¾"-16 UNF−3A

5 pin

Installation of EH

The rod-style version has been developed for direct stroke

measurement in a fluid cylinder.

Mounted on the bottom of the piston, the ring magnet travels over

the rod contactlessly and marks the position exactly through the

rod wall – independent of the hydraulic fluid.

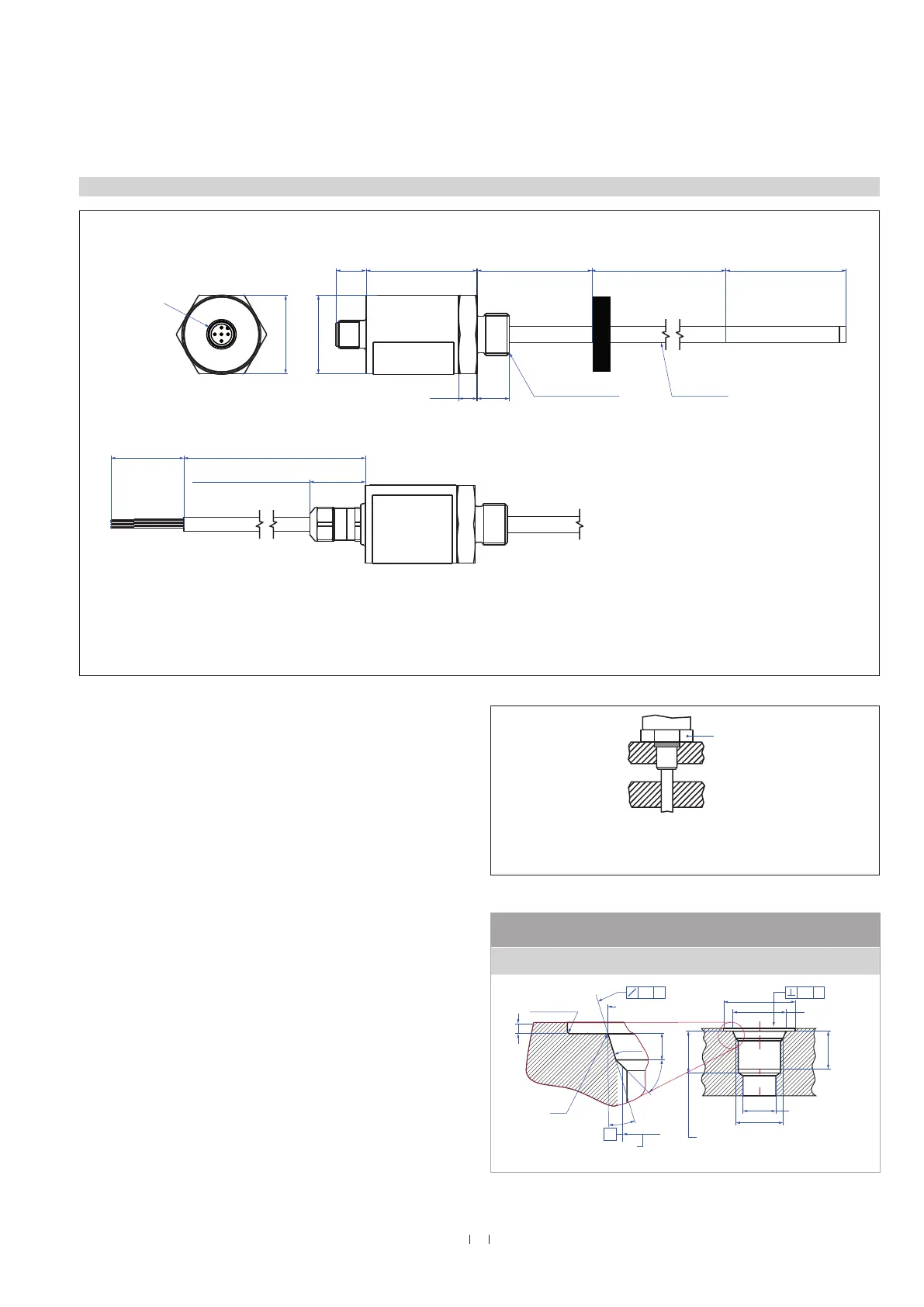

Hydraulics sealing

The sealing via a 15.3 × 2.2 O-ring in the undercut is possible (Fig. 9).

A screw hole based on ISO 6149-1 (Fig. 10) must be provided.

• The flange contact surface must be seated completely on the

cylinder mounting surface.

• The cylinder manufacturer determines the pressure-resistant gasket

(copper gasket, O-ring, etc.).

• The position magnet should not grind on the rod.

• The plunger borehole (Ø 10 mm rod: ≥ Ø 13 mm (≥ Ø 0.52 in.) /

Ø 7 mm rod: ≥ Ø 10 mm (≥ Ø 0.4 in.)) depends on the pressure

and piston speed.

• The peak pressure should not be exceeded.

• Protect the sensor rod from wear using suitable constructive

measures.

With M12 connector

With cable outlet

Fig. 10: Notice for threaded flange M18×1.5-6g lean on DIN ISO 6149-1

Thread

(d

1

×P)

d

2

d

3

d

4

d

5

L

1

L

2

L

3

L

4

Z°

M18×1.5 55 mm

13 mm /

10 mm

24.5 mm 19.8 mm 2.4 mm 28.5 mm 2 mm 26 mm 15°

This dimension applies

when tap drill cannot

pass through entire boss

Thread (d

1

×P)

(Reference size)

Applies at Ød

4

A

R 0.4 max.

L

3

L

1

45° ±5°

Ra 3.2

Ød

5

Ra 3.2

Ød

2

Ra 0.2

Ra 0.1

Pitch diameter

Z°

L

2

L

4

A

0.2 A0.2 A

Ød

3

Fig. 9: Sealing via O-ring 15.3 × 2.2 in the flange undercut

max.

Sealing via O-ring

15.3 × 2.2

(0.6 × 0.09)

Loading...

Loading...