Operation

54 Series 505G2 SilentFlo™ Hydraulic Power Unit

5. If necessary, repeat steps 2 and 3 until the Auto-Cooling Valve is stable and the HPU cools

properly.

6. After the final adjustment, hold the HPU Output Pressure Control to prevent it from moving

while tightening the nut to secure the setting.

7. Verify the output pressure remained at the desired level and the nut to secure the setting.

A. Hold the Auto-Cooling Valve stem to prevent it from turning while tightening the nut.

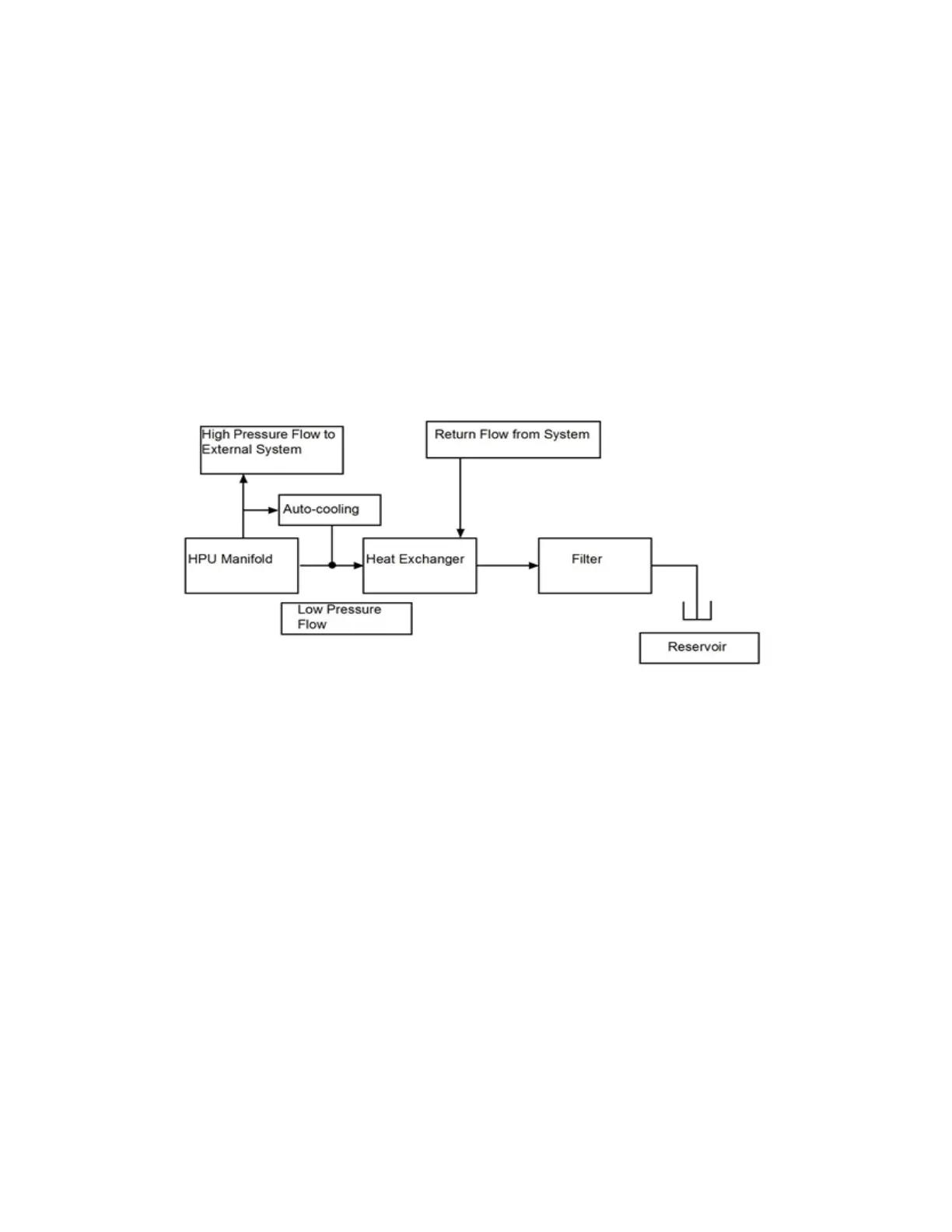

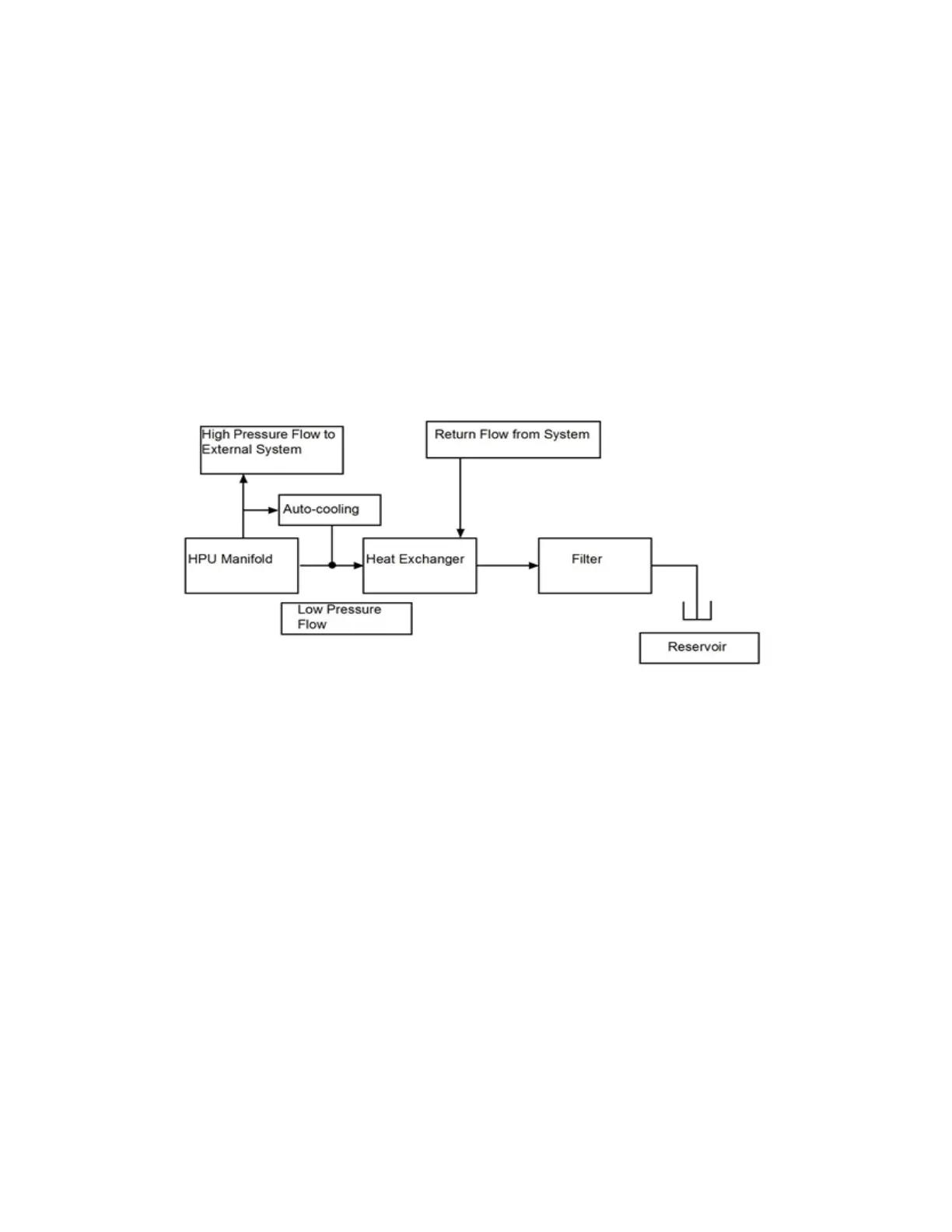

Low/High Pressure Functionality

This section clarifies the low and high pressure functionality of the HPU. There are certain cases

where it is advantageous to use the HPU in low pressure versus high pressure. Low/High functionality

is illustrated in the block diagram below:

Low pressure

Series 505 HPUs are started in low pressure to reduce the amount of current inrush at motor startup.

A solenoid valve that opens a direct flow path to the return line commands the pressure setting.

Because this direct path offers little resistance to the full flow, minimal system pressure is developed

(low pressure). Low pressure operation of a Series 505 HPU provides several useful functions when

high pressure is not required by the external system.

System commissioning

Best practices for system commissioning include flushing the hard line and related equipment. This

process “conditions” the hydraulic fluid to a cleanliness level that supports high performance

servovalve systems. (Refer to the Hydraulic Fluid Care Guide (part number 050-000-536) for

information on fluid cleanliness.)

A logical progression of fluid conditioning that begins at the HPU is required to minimize problems

when commissioning a system.

l With the HPU running in low pressure, acceptable particle counts are obtained in a relatively

short time.

Loading...

Loading...