Special maintenance

After each 2000 hours of opera-

tion

Action 53. Checking the diesel engine

injectors

IMPORTANT! The injectors shall be

cleaned and adjusted in a dealer’s special -

ized worksh o p .

WARNING: Diesel fuel is injected under

high pressure and can be a source of se-

rious injuries, if the injector atomization is

checked by hand. Use a piece of paper

or cardboard for this purpose. Put on pro-

tective goggles. Prior to connection or

disconnection of fuel lines, stop the en-

gine to take pressure down. Prior to start-

ing the engine, tighten all connections of

fuel lines. In case of fuel injection on the

hand skin, immediately apply for medical

aid, otherwise blood poisoning is possi -

ble.

NOTE: It is convenient to have a spare

set of injectors verified and adjusted for

quick installation into the engine.

Take the injectors out and replace them.

To do this, proceed as follows:

• Prior to disconnection or loosening

of any fuel system parts, clean fully

the adjacent working surfaces.

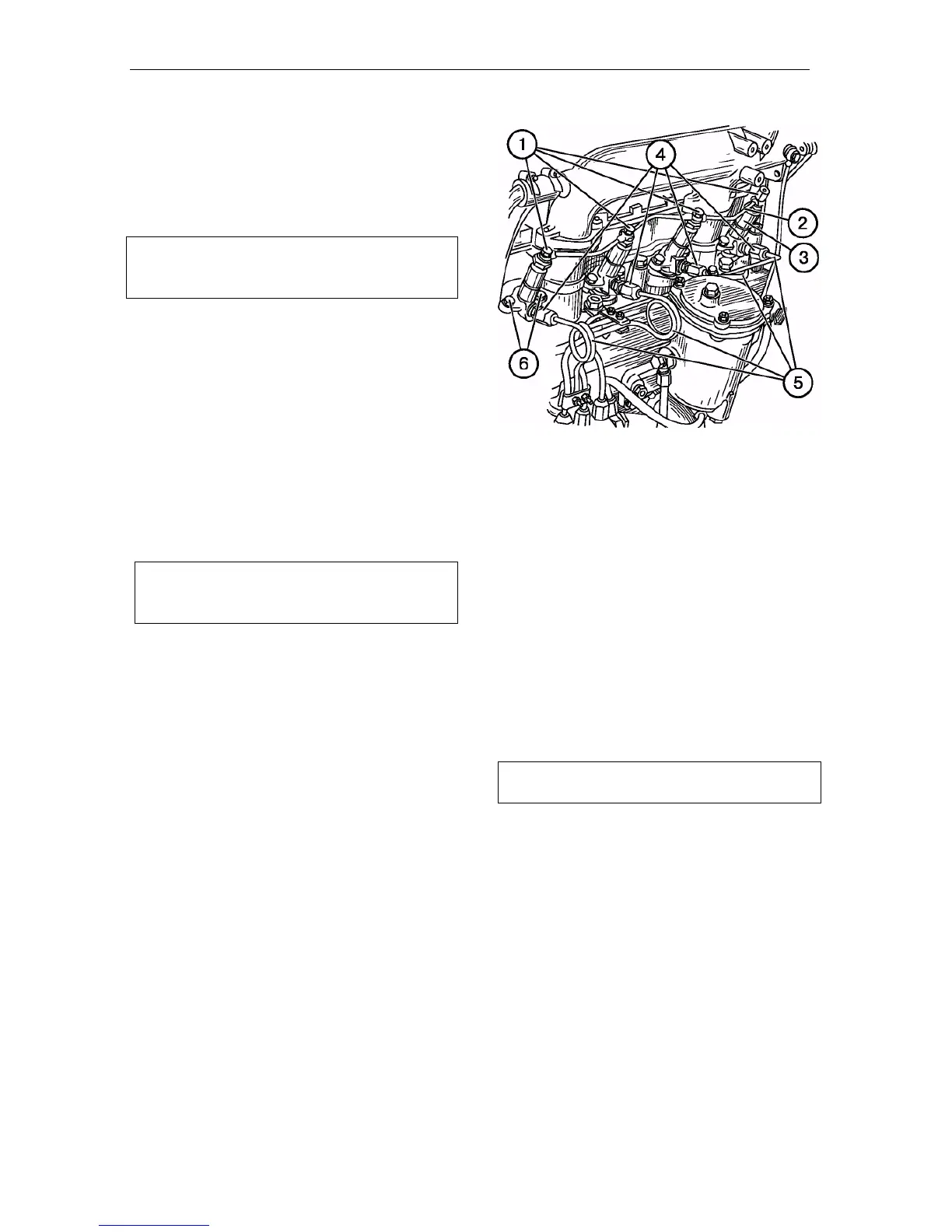

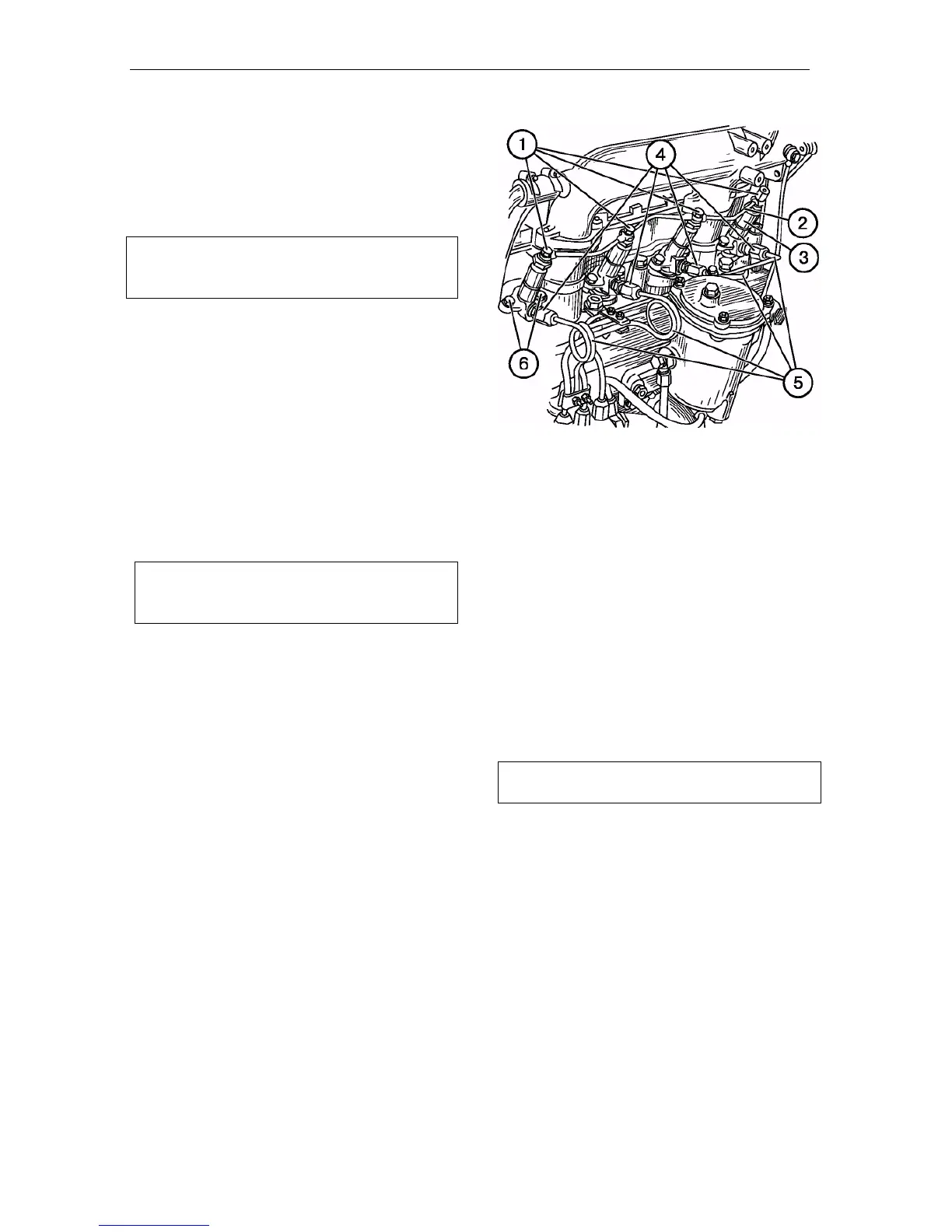

• Turn out the nuts (4) and disconnect

the high-pressure fuel piping (5) from

the injectors (3) and fuel pump.

• Remove the fuel piping.

• Turn out four bolts (1) of the drain

line and take the rundown fuel pip-

ing (2) away. Discard copper seal-

ing washers (two washers per each

“banjo” bolt).

• Unscrew the bolts (6) fastening the in-

jectors and remove the injectors (3).

• Send the injectors for servicing to

dealers workshop.

• Install the verified, cleaned and ad-

justed injectors by performing the

above specified step in the reverse

order.

• Remove air from the system.

IMPORTANT! During each injector in-

stallation, use new copper washers.

Loading...

Loading...