PAGE 42 — MAYCO LS450 CONCRETE PUMP • OPERATION MANUAL — REV. #2 (02/23/21)

MAINTENANCE

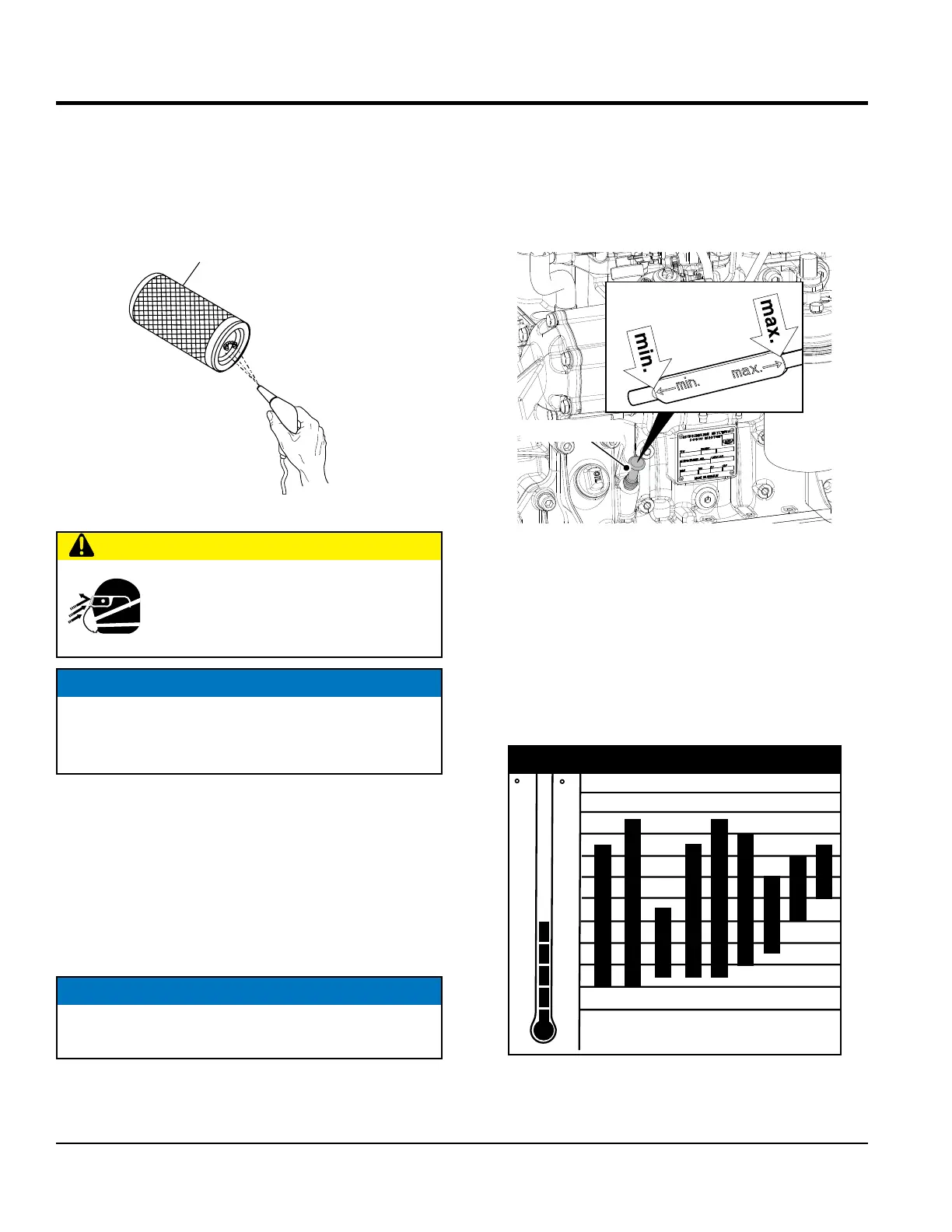

4. To clean the main element (paper air filter), tap the filter

element several times on a hard surface to remove dirt,

or blow compressed air—not to exceed 30 psi (207 kPa,

2.1 kgf/cm

2

)—through the filter element from the inside

out. See Figure 43.

Figure 43. Cleaning Paper Air Filter Elemen

5. Replace the element if it is damaged or excessively

dirty.

6. Clean the inside of the dust pan.

7. Reinstall the element or, if equipped, the precleaner

over the paper air cleaner element.

8. Reinstall the air cleaner dust pan and secure the

latches.

AIR FROM THE

INSIDE OUT

PAPER AIR FILTER

ELEMENT

CAUTION

Wear protective equipment such as

approved safety glasses or face shields

and dust masks or respirators when

cleaning air filters with compressed air.

NOTICE

DO NOT use excessive air pressure or the paper air

filter element will become damaged and will need to

be replaced.

NOTICE

NEVER run the engine with the air cleaner removed or

without an element.

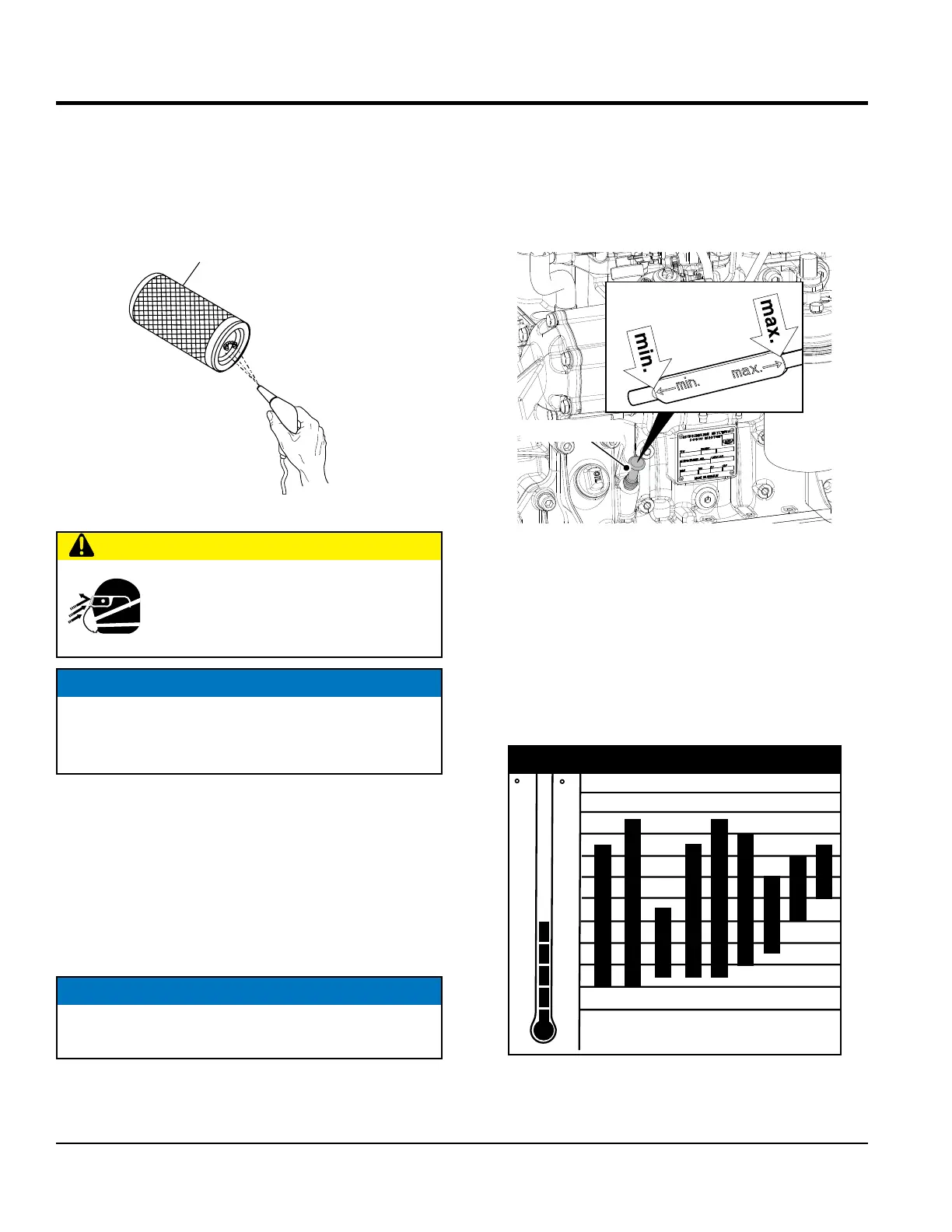

Checking Engine Oil (Daily)

1. When checking or adding oil, place the machine so

the engine is level.

2. Pull the engine oil dipstick (Figure 44) from its holder

and wipe it clean.

Figure 44. Checking Engine Oil Level

3. Reinsert the dipstick.

4. Pull out the dipstick and check the oil level. The oil

should be between the ‘min.’ mark and the ‘max.’ mark

(Figure 44) on the dipstick.

5. If the oil level is low, add the correct amount of engine

oil to bring it to a normal, safe level. See Table 6 for

recommended oil viscosity.

6. Allow enough time for any added oil to make its way

to the oil pan before rechecking the level.

DIPSTICK

Table 6. Oil Selection Chart

-40

-30

-10

-20

-22

-40

-4

-14

032

50

68

86

104

122

10

20

30

40

50

F

C

5W/30

5W/40

10W

10W/30

10W/40

15W/40

20W/20

30

40

OIL: SAE

Loading...

Loading...