PAGE 56 — MAYCO LS450 CONCRETE PUMP • OPERATION MANUAL — REV. #2 (02/23/21)

TRAILER MAINTENANCE

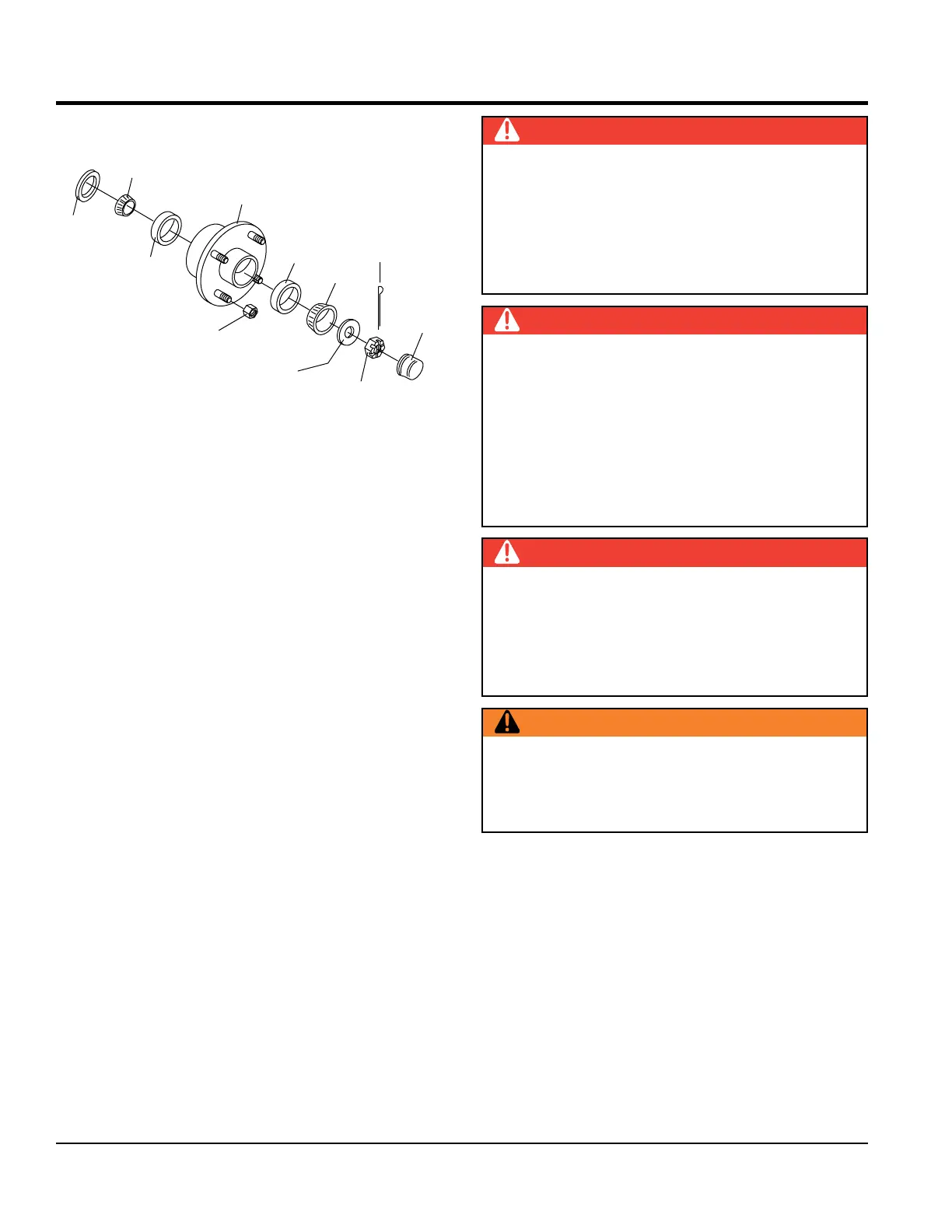

Follow the steps below to disassemble the wheel hub and

service the wheel bearings. See Figure 65.

Figure 65. Wheel Hub Components

1. After removing the dust cap, cotter pin, spindle nut and

spindle washer, remove the hub to inspect the bearings

for wear and damage.

2. Replace bearings that have flat spots on rollers, broken

roller cages, rust or pitting. ALWAYS replace bearings

and cups in sets. The inner and outer bearings are to

be replaced at the same time.

3. Replace seals that have nicks, tears or wear.

4. Lubricate the bearings with a high-quality, EP-2

automotive wheel bearing grease.

Wheel Hub Adjustment

Every time the wheel hub is removed and the bearings are

reassembled, follow the steps below to check the wheel

bearings for free running, and adjust.

1. Turn the hub slowly, by hand, while tightening the

spindle nut until you can no longer turn the hub by hand.

2. Loosen the spindle nut just until you are able to turn it

(the spindle nut) by hand. DO NOT turn the hub while

the spindle nut is loose.

3. Install a new cotter pin through the spindle nut and axle.

4. Check the adjustments. Both the hub and the spindle

nut should be able to move freely. (The spindle nut

motion will be limited by the cotter pin.)

WHEEL

HUB

BEARING

CUP

BEARING

CUP

BEARING

BEARING

OIL

SPINDLE

NUT

SPINDLE

WASHER

COTTER

PIN

CAP

LUG

NUT

DANGER

NEVER crawl under the trailer unless it is on firm and

level ground, resting on properly placed and secured

jack stands.

The possibility exists of the trailer falling, thus causing

equipment damage and severe bodily harm or even

DEATH!

DANGER

When performing trailer inspection and maintenance

activities, you must jack up the trailer using jacks and

jack stands.

When jacking and using jack stands, place them so as

to clear wiring, brake lines, and suspension parts (i.e.

springs and torsion bars). Place jacks and jack stands

inside the perimeter strip on the supporting structure

to which the axles are attached.

DANGER

Improper weld repair will lead to early failure of the trailer

structure and can cause serious injury or DEATH.

DO NOT repair cracked or broken welds unless you

have a certified welder perform the repair. Otherwise,

have the welds repaired by your dealer.

WARNING

If the trailer is involved in an accident, have it inspected

immediately by qualified personnel. In addition, the

trailer should be inspected annually for signs of wear

or deformation.

Loading...

Loading...