2202MYJE-MY-C8-N_2018.02.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 3225**C 5.5 Reassembly

5-48

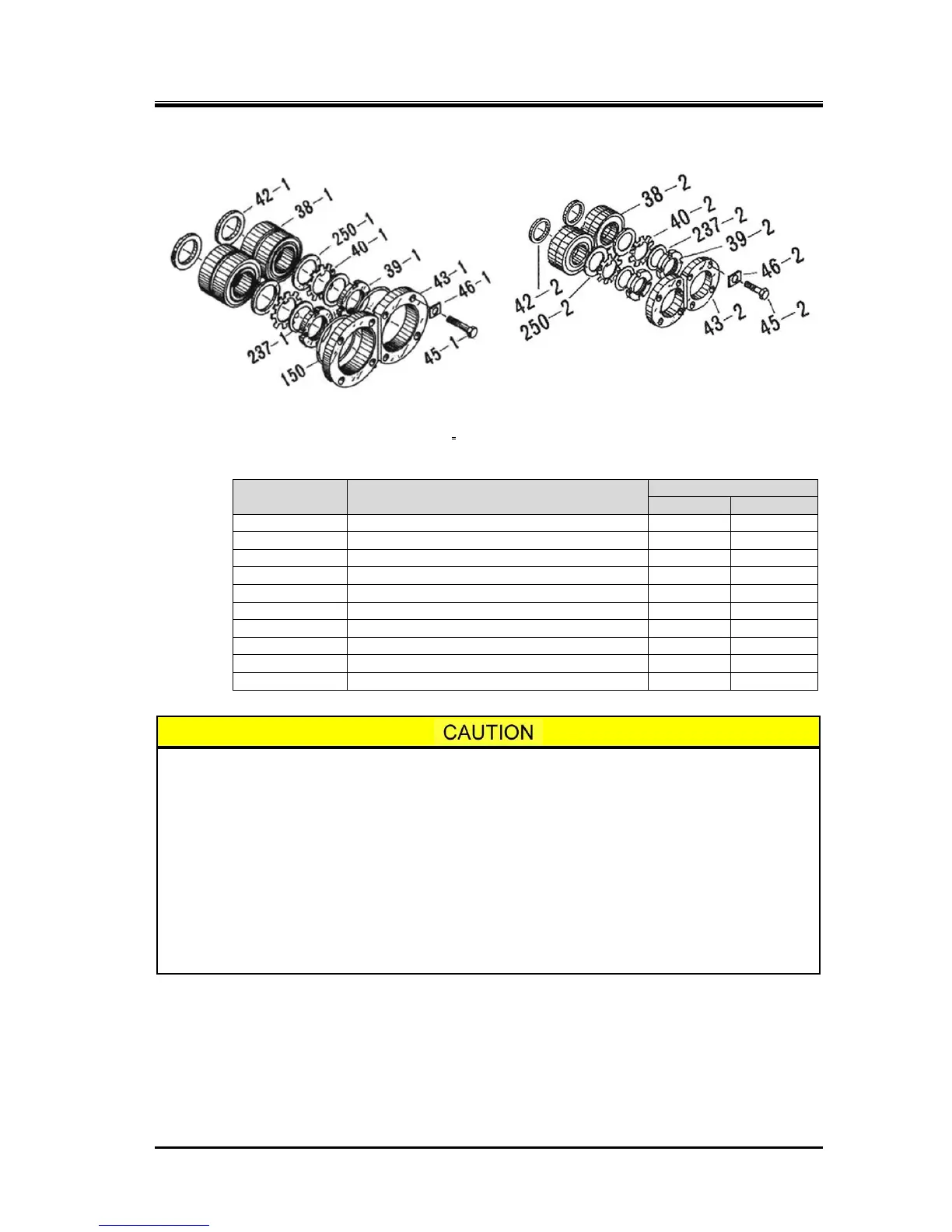

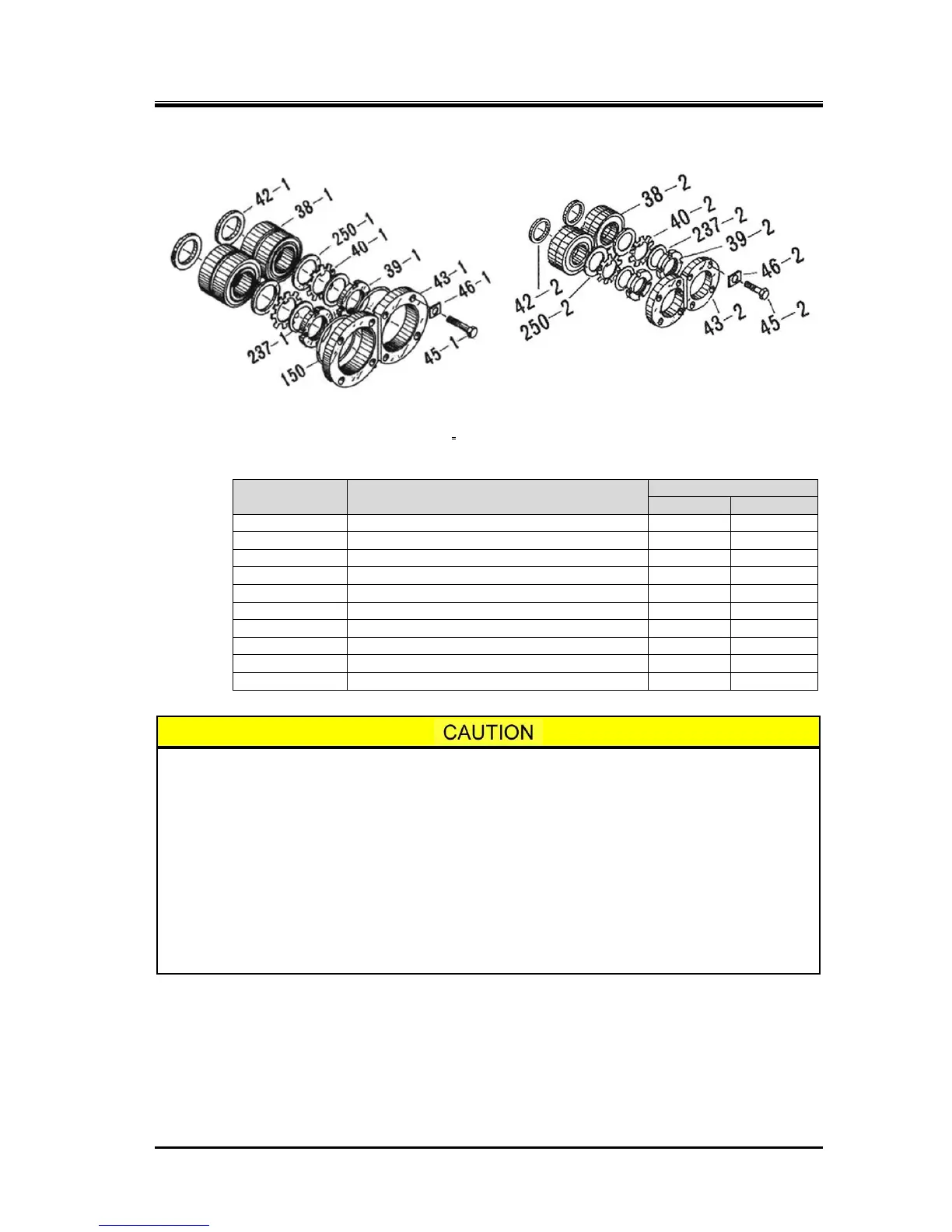

5.5.8 Thrust Bearing Block

The torsional slip washer [237] and lock washer [39] must be replaced with new ones.

If the removed thrust bearing is to be installed as it is, check the marking of "M" or

"F" on the thrust bearing alignment spacer and assemble it in the same combination

as it was disassembled. This is important in controlling the end clearance on the

discharge side of the rotor.

Even if the same bearing is installed, the work must be very carefully done as the

dimension can change if any foreign matter such as a chip of paint or dust is pinched

by the alignment spacer.

In determining the installation direction of the thrust bearing, there are two methods

depending on the existence of an alignment "V" marking on the outer circumference

of the bearing. Install the bearing according to the following procedure provided for

each case.

The assembly sequence for this block is as illustrated in Figure 5-15. The important points to be noted

in the procedure are described below:

a) Check the marking of either "M" or "F" on the thrust bearing alignment spacer to ensure that the

units are assembled in the same combination of parts.

The front and back of the thrust alignment spacer must be distinguished when it is installed. The

larger chamfering side is on the inner machine side, and the smaller chamfering side is on the thrust

bearing side.

Loading...

Loading...